The phrase “Made in China” has long been synonymous with affordability, conjuring images of a vast marketplace brimming with products at prices that seem too good to be true. For entrepreneurs and established businesses alike, the allure of sourcing goods from China is a powerful magnet, promising higher profit margins and a competitive edge. The ultimate question, however, remains a complex one: what is the cheapest way to import from China? The answer, contrary to popular belief, is not found in a simple price tag. The truly cheapest path is not about finding the lowest unit price but about mastering the intricate dance of logistics, supplier relationships, quality control, and strategic planning.

To import cheap products from China successfully is to understand that the advertised price of a product is merely the tip of the iceberg. Beneath the surface lies a substantial body of costs—shipping, tariffs, inspection fees, and potential losses from scams or poor quality—that collectively form the “total landed cost.” This is the real figure you pay to get a product from a factory floor in Guangzhou to your warehouse or customer’s doorstep. Therefore, the most cost-effective import strategy is a holistic one. It involves meticulous China factory sourcing, shrewd negotiation, optimized logistics, and a proactive approach to risk management. This guide will navigate the complexities of sourcing goods from China, moving beyond superficial price points to reveal the comprehensive strategies that genuinely lead to the most economical and sustainable import business.

Before you can minimize your import costs, you must first understand them in their entirety. Focusing solely on the Free on Board (FOB) or Ex-Works (EXW) price is a common mistake that can lead to unexpected expenses and erode your profit margins. The Total Landed Cost (TLC) is the comprehensive calculation of every expense involved in your import journey. Mastering the TLC is the first and most critical step in finding the cheapest way to import from China.

This is the most straightforward component, but it’s not without its nuances. The price you negotiate with your supplier is your starting point. How to contact chinese manufacturers? This is typically quoted in one of two ways:

EXW (Ex-Works): This is the raw cost of the product at the factory gate. You, the buyer, are responsible for all subsequent costs, including transporting the goods from the factory to the port, customs clearance in China, and all shipping and import fees.

FOB (Free on Board): This price includes the cost of the product plus the expense of transporting it to the port of departure in China and clearing it for export. For most importers, FOB is a more manageable starting point as it places the responsibility of local logistics on the supplier, who is better equipped to handle it.

While a lower unit price is always attractive, it’s crucial to balance it against the Minimum Order Quantity (MOQ). A very low price might be tied to a very high MOQ, which increases your upfront investment and inventory risk. Effective negotiation can often lead to a favorable balance between unit cost and MOQ.

This is often the largest and most variable expense in your landed cost calculation. The cost of moving your goods from China to your destination country can fluctuate wildly based on mode, volume, weight, and global demand.

Sea Freight: The most common and cost-effective method for larger shipments. You can choose between a Full Container Load (FCL), where you book an entire container, or Less than Container Load (LCL), where your goods share container space with others.

Air Freight: Significantly faster but also much more expensive than sea freight. It’s suitable for high-value, low-volume goods or urgent shipments.

Express Courier (e.g., DHL, FedEx): The fastest and most expensive option, often used for samples or very small, high-margin orders.

The “cheapest” shipping method is entirely dependent on your specific needs. We will delve deeper into making this choice in a dedicated section later in this guide.

This is a mandatory and often complex cost. When your goods arrive in your country, they must be declared to customs, and you will be required to pay import duties and taxes.

Import Duties/Tariffs: This is a tax levied on imported goods, calculated as a percentage of the total value of the goods plus shipping and insurance costs (the Customs Value). The percentage varies dramatically depending on the product’s category, determined by its Harmonized System (HS) code. Researching the correct HS code for your product before you import is essential for accurate cost planning.

Value Added Tax (VAT) / Goods and Services Tax (GST): Most countries apply a consumption tax to the customs value of the imported goods. This is a significant expense that must be factored into your final retail price.

Failing to declare goods properly or using the wrong HS code can lead to significant fines and delays, adding substantial and unexpected costs.

Inspection & Quality Control Costs

While it may seem like an optional expense, budgeting for quality control (QC) is one of the wisest financial decisions you can make. The cost of a third-party inspection in China (typically a few hundred dollars) is minuscule compared to the potential cost of receiving a shipment of thousands of defective or unsellable products. A proper QC check ensures the goods meet your standards before you make the final payment and ship them, preventing catastrophic losses. Learn about the top 10 inspection companies in China

Payment & Transaction Fees

How you pay your supplier also affects your total cost. International wire transfers (T/T) are common but come with bank fees. Other platforms like PayPal offer more protection but charge higher percentage-based fees, which can be substantial on large orders. Choosing the right payment method for importing from China is a balance between security and cost-efficiency.

The Hidden Costs of a “Cheap” Price

The most significant threats to finding the cheapest way to import from China are the hidden costs that arise from poor planning and execution.

Scams: Falling for a fraudulent supplier who disappears with your deposit.

Defects and Returns: The cost of unsellable goods due to poor quality.

Production Delays: The opportunity cost of missed market windows or stockouts.

Customs Delays: Fees and lost sales from goods being held at the port due to incorrect paperwork.

IP Infringement: The devastating cost of a supplier stealing your design.

Ultimately, the cheapest price on paper can quickly become the most expensive mistake. A strategic approach to sourcing goods from China focuses on minimizing the Total Landed Cost, not just the initial product price.

Your choice of sourcing channel is a primary determinant of your product’s base cost and the level of risk you are willing to assume. The landscape of made in China sourcing is vast and varied, offering multiple avenues to find suppliers. Each channel has a distinct profile of costs, benefits, and risks. Understanding these differences is key to aligning your sourcing strategy with your goal to import cheap products from China.

For most newcomers, the journey begins on massive B2B platforms like Alibaba. These websites are incredible tools, offering a seemingly endless directory of suppliers for virtually any product imaginable. How to order from Alibaba?

Pros:

- Accessibility: Easy to search, filter, and make initial contact with thousands of suppliers from your desk.

- Vast Selection: Unparalleled variety of products and suppliers.

- Low Barrier to Entry: Anyone can start a conversation and request quotes.

Cons & Cost Implications:

- The Middleman Factor: A significant percentage of listings on these platforms are not from actual factories but from trading companies. These middlemen add their own markup, immediately inflating your product cost. It takes considerable skill and effort to differentiate a trading company from a genuine manufacturer.

- Price Inflation: Prices listed are often not the “real” prices. They can be bait-to-switch, or they may not include all specifications, leading to price increases once you are engaged in the process.

- High Risk of Scams and Poor Quality: The anonymity and scale of these platforms make them a breeding ground for scams and low-quality producers. While platforms have introduced verification systems, like the Alibaba Gold Supplier, they are not a foolproof guarantee of quality or reliability. The cost of a bad production run from an unvetted online supplier can be financially devastating.

While B2B platforms are a good starting point for research, relying on them as your sole China factory sourcing method without rigorous, independent verification is rarely the cheapest long-term strategy.

For importers looking to buy existing products in smaller quantities, physical wholesale markets like the famous Yiwu International Trade City are a compelling option. Click for Yiwu wholesale market guide

Pros:

- Low MOQs: You can often buy products in very small quantities, sometimes just a single carton.

- Vast Product Variety: These markets are a physical manifestation of the online B2B platforms, allowing you to see, touch, and compare millions of products.

- Immediate Availability: Products are often in-stock and ready to ship, drastically reducing lead times.

Cons & Cost Implications:

- Higher Unit Prices: Prices here are generally higher than buying directly from a factory in bulk, as you are buying from a wholesaler who has already added their margin.

- Not for Customization: These markets are primarily for off-the-shelf goods. If you need private labeling or custom product development, this is not the right channel.

- Logistical Complexity: You are buying from multiple vendors in a massive complex. Consolidating your goods, arranging quality checks, and managing export logistics can be a nightmare without local assistance. A trip to a place like the Yiwu Market can be overwhelming without a plan.

China wholesale markets can be the cheapest option for retail businesses that need a wide variety of products in small quantities, but the unit price will not be the absolute lowest available in China.

Engaging directly with a Chinese factory is the most straightforward way to eliminate middlemen and achieve the lowest possible unit price. This is the essence of true China factory sourcing.

Pros:

- Lowest Unit Cost: By removing the trading company’s margin, you get the best possible price for the product itself.

- Full Control over Customization: You can work directly with the factory’s engineers to develop custom products, implement private labeling, and control every aspect of production.

- Relationship Building: Direct communication allows you to build a long-term, strategic relationship with your manufacturing partner.

Cons & Cost Implications:

- High MOQs: Factories are set up for mass production and typically require large order quantities to make a production run profitable.

- Difficult to Find and Vet: Finding a reliable, high-quality factory that is willing to work with foreign businesses can be extremely difficult. Many of the best factories do not have a presence on B2B platforms and do not have English-speaking sales staff.

- Communication & Cultural Barriers: Navigating negotiations, production monitoring, and problem-solving can be challenging without a deep understanding of the local business culture and language.

Direct sourcing offers the lowest price ceiling but has the highest barrier to entry and requires the most expertise to execute successfully.

For many businesses, the most effective and, paradoxically, the cheapest way to import from China is by partnering with a professional sourcing company in China. While they charge a fee for their services, their value lies in their ability to dramatically reduce your Total Landed Cost.

Pros & Cost-Saving Mechanisms:

- Access to Better Suppliers: Experienced agents have an established network of pre-vetted, reliable factories that are not accessible to the public. They can match you with the right factory for your specific needs, ensuring a balance of quality and cost.

- Superior Negotiation: A local agent negotiates on your behalf in the local language, leveraging their experience and relationships to secure better prices, lower MOQs, and more favorable payment terms than you could likely achieve on your own.

- Reduced Risk: They perform on-the-ground due diligence, factory audits, and quality control inspections, drastically minimizing your risk of scams and quality issues. This preventative action saves enormous amounts of money in the long run.

- Logistical Efficiency: They manage the entire process, from placing the order to consolidating goods and coordinating shipping, ensuring a smooth and cost-effective logistics chain.

A good sourcing partner, like our team at Maple Sourcing, is an investment in cost reduction. Their fee is often more than offset by the savings they generate in product cost, mistake prevention, and logistical optimization. Exploring professional sourcing services can be the most strategic shortcut to making your import venture both cheaper and safer.

Click for Sourcing Agent Fee Structure

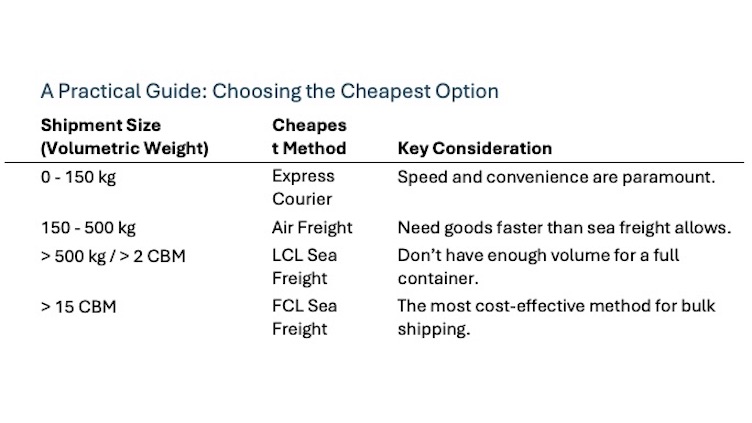

Shipping is the great variable in the import cost equation. The right choice can save you thousands of dollars, while the wrong one can turn a profitable order into a loss. The cheapest way to import from China from a logistics perspective is not a one-size-fits-all answer; it is a strategic decision based on the volume, weight, and urgency of your shipment.

This is the all-in-one, door-to-door service that most people are familiar with. It is by far the fastest and simplest option, but also the most expensive for anything other than very small shipments.

Best For: Shipments under 150kg, product samples, urgent orders.

Cost Structure: Priced per kilogram, with rates decreasing as weight increases. The price is all-inclusive, covering transport, customs clearance, and delivery to your door.

When is it “Cheapest”? Express courier is the cheapest method only when speed is your absolute priority or for very light shipments (e.g., under 45kg) where the convenience outweighs the higher cost per kilogram compared to air freight. For product samples, it is the undisputed best choice.

Air freight is a step down from express courier in terms of speed and cost. It involves moving goods from one major airport to another. It does not typically include door-to-door service; you or a customs broker will need to handle customs clearance and final delivery.

Best For: Shipments between 150kg and 500kg, high-value goods, time-sensitive inventory.

Cost Structure: Priced per kilogram, but generally cheaper than express courier for heavier shipments. The cost includes transport to the destination airport. You will have additional costs for customs brokerage, duties, and inland transportation.

When is it “Cheapest”? Air freight hits a sweet spot for medium-sized shipments that are too heavy to be cost-effective for express but are still needed faster than a sea voyage would allow. It offers a balance of speed and cost for valuable or seasonal products.

For any shipment over about 2 cubic meters or 500kg, sea freight is almost always the cheapest option per unit. It is the backbone of global trade. The journey is much slower (30-40 days on average), but the cost savings are immense for bulk orders. You have two primary choices in sea freight. For a detailed comparison, understanding FCL vs. LCL is crucial.

FCL (Full Container Load)

You rent an entire container (typically 20ft or 40ft). You have exclusive use of the space.

Best For: Large shipments, typically over 15 cubic meters.

Cost Structure: You pay a flat rate for the container. This is extremely cost-effective if you can fill it, as the cost per cubic meter becomes very low.

When is it “Cheapest”? FCL is the absolute cheapest way to ship goods on a per-unit basis if your order volume is large enough to justify a full container. It is also faster and safer than LCL, as the container is sealed at the factory and not opened until it reaches you, reducing the risk of damage or loss.

LCL (Less than Container Load)

Your goods are consolidated with other importers’ goods to fill a container.

Best For: Shipments that are too large for air freight but too small for FCL (e.g., 2-15 cubic meters).

Cost Structure: You pay based on the volume (in cubic meters) or weight of your goods, whichever is greater. While the total cost is less than booking a full container, the price per cubic meter is significantly higher than FCL.

When is it “Cheapest”? LCL is the cheapest option for small-to-medium-sized bulk orders. It allows businesses to benefit from the low cost of sea freight without needing to place massive factory orders. However, LCL shipments are more prone to delays (due to the consolidation/deconsolidation process) and have a slightly higher risk of damage.

The Incoterm you agree upon with your supplier has a direct impact on your logistics costs and responsibilities. The most common are:

EXW (Ex-Works): You are responsible for all shipping costs, including picking up the goods from the factory. This can seem cheap upfront but adds local logistics costs in China.

FOB (Free on Board): The supplier’s price includes getting the goods to the Chinese port. You pay for the sea/air freight and all subsequent costs. This is the most common and often the most balanced term for importers.

CIF (Cost, Insurance, and Freight): The supplier’s price includes shipping to your destination port. This seems convenient, but you often pay a premium as the supplier chooses the freight forwarder, and you can face high, unexpected destination charges. FOB generally gives you more control and is often cheaper in the end.

Mastering logistics is a core part of the strategy for sourcing goods from China economically.

Finding the cheapest way to import from China is not about one-time tricks; it’s about building a system of smart, repeatable practices that continuously drive down your Total Landed Cost. These proactive strategies focus on preventing costly errors, optimizing relationships, and making informed decisions at every stage of the import process. This is where the art of made in China sourcing truly shines.

Your cost-saving efforts begin before you even contact a supplier. The type of product you choose to import has inherent cost implications.

Research HS Codes: Before committing to a product, research its Harmonized System (HS) code to determine the import duty rate in your country. Some products have very low or even zero tariffs, while others can be prohibitively high. Choosing products in lower tariff bands is an immediate and significant cost saving.

Simplicity and Durability: Complex products with many components or fragile materials are more expensive to manufacture and have a higher risk of defects and shipping damage. Sourcing simpler, more durable products can lead to lower production costs and fewer quality-related losses.

Size and Weight: As established, shipping costs are a major factor. Sourcing smaller, lighter products will dramatically reduce your logistics expenses, making it easier to import cheap products from China profitably.

Negotiation is a critical skill, but it’s not just about haggling for a lower price. A holistic negotiation strategy can reduce costs across the board.

Go Beyond Price: While negotiating the unit price is important, also focus on the Minimum Order Quantity (MOQ). A lower MOQ reduces your upfront capital investment and inventory risk. Also, negotiate payment terms. Moving from a 30/70 (30% deposit, 70% on completion) to a 20/80 or even 10/90 split can significantly improve your cash flow. Click to learn How to negotiate lower MOQ?

Demonstrate Long-Term Value: Suppliers are more likely to offer better terms to customers they see as long-term partners. Share your business goals and growth plans. Position your initial order as a trial for a larger, ongoing relationship.

Be Specific and Prepared: The more detailed your product specifications are, the more accurate your quote will be and the less room there is for unexpected price increases later. Provide clear technical drawings, material requirements, and packaging standards.

In Chinese business culture, the concept of "Guanxi" is paramount. It translates roughly to relationships, networks, or connections, but its significance runs much deeper. It’s a system of mutual trust, obligation, and goodwill built over time. While foreign importers can’t be expected to become masters of Guanxi overnight, understanding and respecting its principles can be a powerful tool for cost reduction. A supplier who views you as a long-term, respectful partner—not just a transactional customer—is more likely to:

Offer Better Pricing: They will often provide their best prices to trusted partners, sometimes even absorbing small increases in material costs to maintain the relationship.

Provide Production Priority: When the factory is busy, your orders may get moved to the front of the line, reducing lead times and preventing costly delays.

Be More Flexible: A trusted partner is more willing to negotiate on MOQs, offer better payment terms, or work with you to solve problems collaboratively when they arise. Building this relationship involves clear communication, paying on time, visiting the factory if possible, and showing loyalty. This “soft” investment in the relationship often yields hard, tangible cost savings that won’t appear on any initial quote.

Choosing the wrong supplier is the single most expensive mistake you can make. The “cheap” price from an unreliable factory can lead to total loss. A thorough vetting process is a crucial investment.

Background Checks: Go beyond the supplier’s website. Ask for their business license, quality certifications (like ISO 9001), and bank account details. Verify that the company name is consistent across all documents.

Factory Audits: For any significant order, a physical factory audit is non-negotiable. An China supplier reliability audit, which can be performed by a third-party service or a sourcing agent, verifies that the factory is a real, capable manufacturer and not just a trading company in a small office. Factory audit in China assesses their production capacity, quality management systems, and social compliance. This upfront cost prevents you from sending thousands of dollars to a supplier who is incapable of delivering.

Skipping quality control (QC) inspections to save a few hundred dollars is the definition of “penny wise, pound foolish.” A China quality control inspection service is your insurance policy against catastrophic quality failure.

Pre-Shipment Inspection in China (PSI): This is the most common type. An inspector visits the factory when your order is 100% complete and at least 80% packed. They perform a random inspection based on established standards (AQL - Acceptance Quality Limit) to check for defects, verify specifications, and ensure proper packaging.

Catching Problems Early: A PSI allows you to identify and address any quality issues before you make the final payment and the goods leave China. It gives you the leverage to have the supplier fix the defects or to renegotiate the price. Without this step, your only recourse is to deal with a container of faulty products that have already arrived at your warehouse, a far more expensive problem.

For businesses that don’t have enough volume from a single supplier to fill a container, shipment consolidation is a highly effective cost-saving strategy. Instead of shipping multiple small LCL or air freight shipments from different suppliers—each with its own set of fixed destination and clearance fees—you can have them consolidated into a single, larger shipment. A sourcing agent or a good freight forwarder can manage this process. They provide a warehouse address where your various suppliers can send their goods. Once all orders have arrived and been inspected, they are packed together into a single LCL or FCL shipment under one bill of lading. This approach saves a significant amount of money by minimizing redundant handling fees, customs clearance charges, and inland transportation costs at the destination. It transforms multiple expensive, small shipments into one larger, more economical one.

Your payment strategy can also yield significant savings. Click for Best Online Payment Processors for Small Business

Avoid 100% Upfront: Never pay 100% of the order value upfront. This gives you no leverage if something goes wrong. A standard split is 30% to start production and 70% after a successful pre-shipment inspection.

Choose Cost-Effective Methods: For large transactions, international wire transfers (T/T) are generally the most cost-effective, despite the flat fees. For smaller orders or samples, platforms like PayPal or Wise can be good options, but be mindful of their percentage-based fees on larger amounts. Always clarify who pays the fees with your supplier.

By implementing these proactive strategies, you move from being a reactive buyer to a strategic sourcer, building a resilient and cost-effective supply chain that is the true hallmark of successful China factory sourcing.

The pursuit of the cheapest way to import from China is a journey that leads to a profound conclusion: the cheapest path is rarely the most obvious one. It is not found by simply sorting search results by “price: low to high.” It is a strategic process built on a deep understanding of the Total Landed Cost, a diligent approach to sourcing and vetting partners, and an unwavering commitment to quality control.

To import cheap products from China sustainably is to recognize that true cost savings come from preventing expensive mistakes. A few extra dollars spent on a factory audit can save you from a five-figure loss on a fraudulent order. A few hundred dollars invested in a quality inspection can prevent a container of unsellable goods from ever leaving the port. The time invested in building a strong relationship with a reliable supplier will pay dividends in better pricing, consistent quality, and smoother operations for years to come.

Ultimately, the most cost-effective strategy involves leveraging expertise at every turn. Whether it’s the expertise you develop yourself through meticulous research and experience, or the on-the-ground expertise of a professional partner, knowledge is your greatest cost-saving tool. A sourcing partner can be an accelerator, providing immediate access to the networks, negotiation skills, and risk-mitigation processes that would take years to build independently. They transform the complex landscape of China factory sourcing into a manageable and profitable venture.

So, what is the cheapest way? It is the smartest way. It is the way of diligence, foresight, and strategic partnership. It is the path that looks beyond the price tag to build a resilient, efficient, and truly profitable supply chain from the heart of global manufacturing to your front door. To begin your journey on this smarter path, we encourage you to learn more about how expert product sourcing from China can redefine your business.