For any business involved in importing goods, particularly from manufacturing hubs like China, maintaining product quality is paramount. Receiving a shipment of substandard products can lead to financial losses, damaged reputation, customer dissatisfaction, and even legal issues. While 100% inspection of every single item might seem like the ideal solution, it’s often impractical, time-consuming, and prohibitively expensive, especially for large orders. This is where a statistically sound method known as AQL sampling comes into play. Understanding what is AQL sampling and how to effectively use it can be a game-changer for your import business, allowing you to manage quality control efficiently and make informed decisions about your shipments.

This comprehensive guide will delve into the intricacies of the AQL standard, explain how to use an AQL sampling chart or AQL sampling table, and demonstrate how to apply AQL inspection to safeguard your import business.

Before diving deep into AQL, it’s essential to underscore why quality control (QC) is non-negotiable in international trade. When you’re sourcing products from overseas suppliers, thousands of miles away, you lose the direct oversight you might have with local production. Issues like:

Supplier Misunderstanding: Your specifications might be misinterpreted.

Production Shortcuts: Factories might cut corners to save costs, especially if unsupervised.

Inconsistent Output: Quality can vary significantly from one batch to another or even within the same batch.

Damage During Transit: Goods might be perfectly manufactured but poorly packed, leading to damage.

A robust QC process helps mitigate these risks. It involves setting clear quality expectations, verifying that these expectations are met before goods are shipped, and having a plan to address any deviations. An AQL inspection is a cornerstone of such a process for many importers. Learn about our comprehensive Product Sourcing Service that include quality management.

So, what is AQL sampling? AQL stands for Acceptance Quality Limit (sometimes referred to as Acceptable Quality Level). It is a statistical sampling method used for quality control inspections, predominantly for product inspections before shipment.

In essence, AQL represents the maximum percentage of defective items in a batch (or lot) that, for the purpose of sampling inspection, can be considered satisfactory as a process average. It’s crucial to understand that AQL is not a guarantee that a batch contains no more than that percentage of defects. Instead, it’s a statistical tool that helps an importer decide whether to accept or reject a production lot based on the inspection of a randomly selected sample of units.

Benefits of Using AQL Sampling for Importers:

Cost-Effective: Inspecting a sample is significantly cheaper and faster than inspecting 100% of the goods.

Statistically Valid Decisions: Provides a scientific and objective basis for accepting or rejecting a shipment, rather than relying on gut feelings or haphazard checks.

Clear Expectations: Sets a clear, measurable AQL standard for your suppliers regarding acceptable quality levels.

Risk Management: Helps manage the risk of accepting a batch with an unacceptably high number of defects.

Versatility: Can be applied to a wide range of products, from electronics and textiles to furniture and toys.

Understanding what is AQL sampling is the first step towards implementing a more professional and effective quality control system for your import business.

To effectively use AQL sampling, you need to be familiar with its key components and terminology, which are primarily found within the AQL sampling chart or AQL sampling table.

1. Lot Size (N)

The “lot size” refers to the total number of units in the production batch being inspected. For example, if you ordered 5,000 t-shirts, your lot size (N) is 5,000. This is the starting point for determining your sample size.

2. Inspection Levels

Inspection levels determine the relationship between the lot size and the sample size. There are generally two types:

General Inspection Levels (I, II, III): These are the most commonly used.

Level I: Used when less discrimination is needed (e.g., when a supplier has a good track record, or inspection costs are very high relative to the value of the product). It results in a smaller sample size.

Level II: This is the default and most commonly used level for consumer products. It offers a good balance between inspection cost and risk assurance. Unless specified otherwise, Level II is typically assumed for an AQL inspection.

Level III: Used when more discrimination is needed (e.g., for high-value items, critical safety components, or when a supplier has a poor quality history). It results in a larger sample size, providing greater confidence.

Special Inspection Levels (S-1, S-2, S-3, S-4): These are used for specific types of tests, particularly when inspections are destructive, very costly, or time-consuming, and only a very small sample size is practical. For example, testing the breaking strength of a chair leg might be destructive. These levels result in much smaller sample sizes than General Inspection Levels.

The choice of inspection level directly impacts the number of units you will inspect.

3. Defect Classification

Not all defects are created equal. In AQL sampling, defects are typically categorized into three types:

Critical Defects: A defect that fails to meet mandatory regulations or poses a safety hazard to the user. For example, a sharp edge on a toy, incorrect electrical wiring, or presence of banned substances. Products with even one critical defect are generally considered unacceptable. Therefore, the AQL for critical defects is almost always set to 0%, meaning if even one critical defect is found in the sample, the entire lot is typically rejected.

Major Defects: A defect that is likely to result in product failure, significantly reduce its usability or saleability, or is a very obvious appearance flaw. Examples include a non-functional electronic device, a garment with a large tear, or a piece of furniture that is unstable. Importers typically set an AQL of 1.5% or 2.5% for major defects.

Minor Defects: A defect that does not significantly affect the product’s usability or function but represents a deviation from the agreed specifications. It might be a minor cosmetic flaw or an imperfection that most users wouldn’t notice or be bothered by. Examples include a loose thread on a garment, a small scratch on an inconspicuous part of a product, or slightly inconsistent color. A common AQL for minor defects is 4.0%.

Defining these defect classifications clearly in your product specification sheet is crucial for an effective AQL inspection.

4. AQL Values

The AQL value itself is the maximum percentage of a specific type of defect (Critical, Major, or Minor) that is considered acceptable in the batch. For instance, if you set an AQL of 2.5% for major defects, you are indicating that you are willing to accept batches that, on average, have no more than 2.5% major defects. Different AQLs are set for each defect category (e.g., Critical 0%, Major 2.5%, Minor 4.0%).

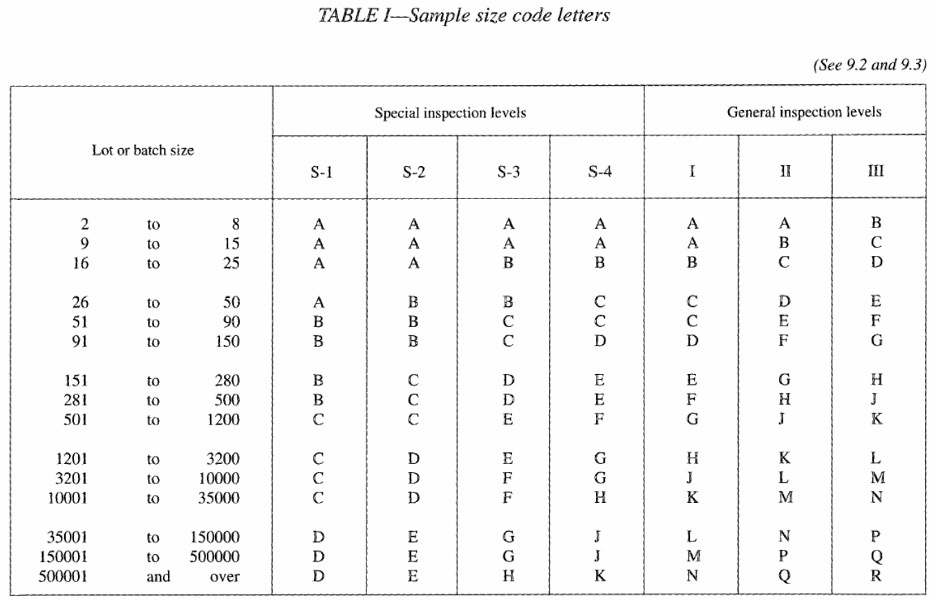

5. Sample Size Code Letter

This is a letter (e.g., A, B, C… Q, R) derived from the AQL sampling chart (specifically Table I) based on your chosen Lot Size and General Inspection Level. This code letter is then used to find the actual sample size.

6. Sample Size (n)

This is the specific number of units that will be randomly selected from the total lot for inspection. It is determined using the Sample Size Code Letter and referring to the main AQL sampling table (Table II).

7. Acceptance Number (Ac) and Rejection Number (Re)

For each defect type and its corresponding AQL, the AQL sampling table will provide two numbers:

Acceptance Number (Ac): The maximum number of defects of that type allowed in the inspected sample for the lot to be accepted.

Rejection Number (Re): The minimum number of defects of that type that will cause the lot to be rejected. Typically, Re = Ac + 1.

For example, if for major defects, Ac = 5 and Re = 6, it means if 5 or fewer major defects are found in the sample, the lot is accepted (for major defects). If 6 or more major defects are found, the lot is rejected.

Using an AQL sampling table (like those based on ISO 2859-1 or ANSI/ASQ Z1.4) might seem intimidating at first, but it’s a straightforward process once you understand the steps. There are typically two main tables involved.

Table I: Sample Size Code Letters This table cross-references the Lot Size with the chosen Inspection Level (General I, II, III, or Special S-1 to S-4) to give you a Sample Size Code Letter.

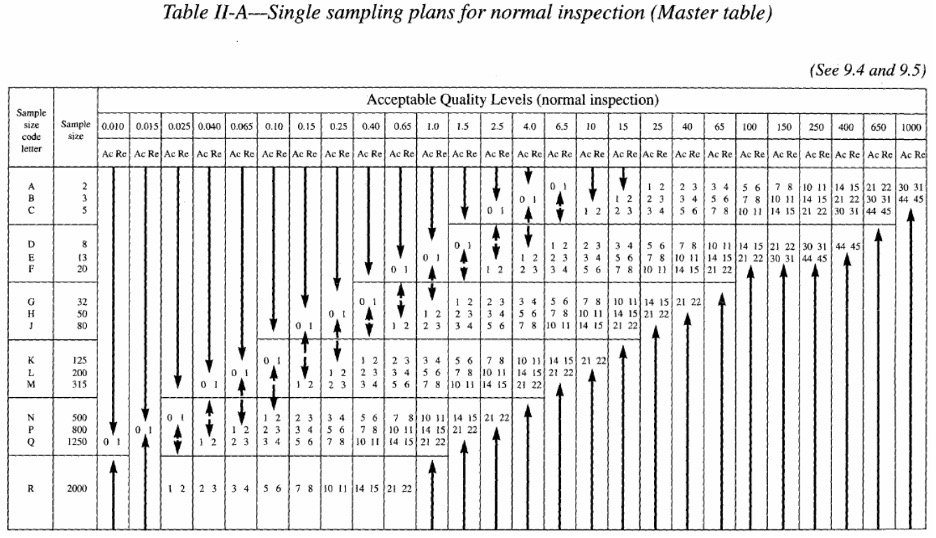

Table II: Single Sampling Plans for Normal Inspection (Master Table) This table uses the Sample Size Code Letter (from Table I) and your chosen AQL values for critical, major, and minor defects to determine:

* The Sample Size (n) to inspect.

* The Acceptance (Ac) and Rejection (Re) numbers for each defect type.

Step-by-Step Guide:

Let’s walk through an example. Suppose you are importing 8,000 units of a product (Lot Size = 8,000). You decide to use General Inspection Level II, and your desired AQLs are: * Critical Defects: 0% * Major Defects: 2.5% * Minor Defects: 4.0%

1. Determine Lot Size (N):

N = 8,000 units.

2. Choose Inspection Level:

You’ve chosen General Inspection Level II.

3. Find the Sample Size Code Letter (from Table I):

Look at Table I. Find the row corresponding to your lot size range (e.g., 3,201 to 10,000). Move across that row to the column for General Level II.

This will give you a Sample Size Code Letter. For a lot size of 8,000 and Level II, the code letter is typically L.

4. Choose AQL Values for Critical, Major, and Minor Defects:

Critical: 0%

Major: 2.5%

Minor: 4.0%

5. Use the Sample Size Code Letter and AQL values in Table II to find Sample Size (n) and Ac/Re numbers:

Look at Table II-A (Single sampling plans for normal inspection). Find the row corresponding to your Sample Size Code Letter (L).

The first column in this row will tell you the Sample Size (n). For code letter L, the sample size is typically 200 units.

Now, look across row L to the columns corresponding to your chosen AQLs:

For Critical Defects (AQL 0%): Find the column for AQL 0%. The table will likely show Ac=0, Re=1. This means if even 1 critical defect is found in the sample of 200, the lot is rejected for critical defects.

For Major Defects (AQL 2.5%): Find the column for AQL 2.5%. For sample size 200 (Code L), you might find Ac=10, Re=11. This means if 10 or fewer major defects are found, the lot is accepted for major defects. If 11 or more are found, it’s rejected.

For Minor Defects (AQL 4.0%): Find the column for AQL 4.0%. For sample size 200 (Code L), you might find Ac=14, Re=15. This means if 14 or fewer minor defects are found, the lot is accepted for minor defects. If 15 or more are found, it’s rejected.

So, for your order of 8,000 units, using General Level II and AQLs of 0/2.5/4.0, you would need to randomly inspect 200 units. The lot passes if:

0 critical defects are found, AND

No more than 10 major defects are found, AND

No more than 14 minor defects are found.

If any of these conditions are not met, the AQL inspection “fails,” and the lot is considered rejected according to the AQL standard.

Knowing how to read an AQL sampling chart is one thing; applying it effectively is another.

1. When to Conduct an AQL Inspection

The most common time to perform an AQL inspection is during a Pre-Shipment Inspection (PSI). A PSI is typically conducted when 100% of the goods are produced and at least 80% are packed for export. This is your last chance to check quality and make a data-driven decision before the goods leave the factory and payment is finalized.

2. Integrating AQL Standard into Agreements

Your chosen AQL levels should be clearly communicated and agreed upon with your supplier before production begins. Include them in your Purchase Order (PO) and any formal Quality Agreement. This sets clear expectations and provides a basis for action if quality issues arise. For example, your PO could state: “Quality inspection will be performed as per AQL General Level II, Critical 0%, Major 2.5%, Minor 4.0%, based on ISO 2859-1.”

3. Clear Defect List

Alongside AQLs, provide your supplier and inspection team with a detailed “defect classification list” specific to your product. This list should clearly define what constitutes a critical, major, and minor defect for your item, ideally with photographic examples. This reduces subjectivity during the AQL inspection. For instance, for furniture, a “wobbly leg” might be a major defect, while a “small scratch on an underside surface” might be minor.

If the number of defects found in the sample exceeds the acceptance number (Ac) for any category (Critical, Major, or Minor), the lot fails the AQL inspection. You then have several options:

1. Reject the Entire Lot: You can refuse the shipment. This is a strong stance and depends on your contract terms.

2. Negotiate a Re-work: Ask the supplier to sort out the defective items and re-work or replace them. A re-inspection would then be necessary (often at the supplier’s expense).

3. Require Supplier to Sort the Batch: The supplier inspects all units and removes/reworks defective ones.

4. Pay for a Third-Party to Sort: If feasible and urgent, you might arrange for a third party (or your own team if locally present) to sort the goods, with the cost potentially borne by the supplier.

5. Accept the Lot with a Discount: If the defects are not critical and you can still use or sell the products, you might negotiate a discount from the supplier.

The decision will depend on the severity of the defects, your relationship with the supplier, contractual terms, and market urgency.

The “right” AQLs and inspection levels are not one-size-fits-all. They depend on several factors:

Product Type and Value: For high-value products (e.g., electronics, medical devices) or items where safety is critical, you’d use stricter AQLs (e.g., Major 1.0% or 1.5%) and potentially a higher inspection level (Level III). For low-cost promotional items, you might accept a higher AQL (e.g., Major 4.0%) and use Level I or II.

Target Market Expectations: Luxury markets demand near-perfect quality, necessitating stricter AQLs. Discount markets might tolerate more minor imperfections.

Importer’s Risk Tolerance: How much risk are you willing to take? A more risk-averse importer will opt for stricter AQLs and higher inspection levels.

Supplier’s Historical Performance: If a supplier has a proven track record of excellent quality, you might eventually move to a reduced inspection level (e.g., Level I). Conversely, if a supplier has previous quality issues, you might enforce Level III.

Cost of Inspection vs. Cost of Defects: Balance the cost of performing more rigorous inspections against the potential cost of dealing with defective products (returns, reputation damage, lost sales).

Commonly Used AQLs for Consumer Goods: A very common starting point for general consumer goods is:

* Critical Defects: 0%

* Major Defects: 2.5%

* Minor Defects: 4.0%

And General Inspection Level II.

When to Use Different General Inspection Levels:

* Level I: Use if your supplier has a great track record, or if the product is low risk/low value. Fewer samples are inspected, saving time and money, but with less assurance.

* Level II: Standard choice, offering a good balance.

* Level III: Use for high-risk products, new suppliers, or if previous shipments had issues. More samples are inspected, providing higher assurance but at a greater cost.

When to Use Special Inspection Levels (S-1, S-2, S-3, S-4): These are chosen when the inspection process itself is particularly involved or destructive. For example:

* Carton dropping test for packaging.

* Cycle testing for a switch (e.g., 5,000 on/off cycles).

* Fabric GSM (grams per square meter) check requiring a piece to be cut.

These levels lead to very small sample sizes (e.g., 2, 3, 5, 8 units) and are used for specific tests on an attribute, not for the overall workmanship assessment which would still use General Levels.

The advantages of properly implementing AQL sampling are significant:

1. Objective Decision-Making: Removes guesswork and emotional bias from the acceptance/rejection decision. The data from the AQL inspection guides your choice.

2. Cost-Effectiveness: Far more economical than 100% inspection, especially for large volumes, while still providing a reasonable level of quality assurance.

3. Proactive Risk Management: Helps identify and mitigate quality risks before products are shipped and paid for in full.

4. Supplier Accountability: Clearly defined AQL standard makes suppliers aware of your quality expectations and holds them accountable for meeting them.

5. Consistency in Quality Assessment: Provides a standardized and repeatable method for evaluating product quality across different suppliers and shipments.

6. Improved Product Quality Over Time: Consistent application of AQL inspections often motivates suppliers to improve their internal QC processes to avoid rejections.

7. Reduced Defects Reaching Customers: Leads to higher customer satisfaction and fewer returns or warranty claims.

While powerful, AQL sampling is not a silver bullet and has limitations:

1. Not a Guarantee of Zero Defects: A key misconception is that an accepted lot under AQL means it’s defect-free. An AQL of 2.5% for major defects explicitly allows for up to 2.5% major defects in the batch on average. You are accepting a certain level of risk.

2. Statistical Risk: Since only a sample is inspected, there’s always a statistical chance that the sample is not perfectly representative of the entire lot. A good lot might be rejected (producer’s risk), or a bad lot might be accepted (consumer’s risk). AQL plans are designed to balance these risks.

3. Doesn’t Improve Quality Directly: AQL inspection is an assessment tool, not a quality improvement tool. It tells you the quality level of a batch; it doesn’t fix underlying production process issues. Quality must be built into the product from the design and manufacturing stages.

4. Effectiveness Depends on Correct Application:

Accurate Lot Size: If the reported lot size is incorrect, the sample size might be inappropriate.

Proper Random Sampling: The sample must be randomly selected to be representative. Inspectors must be trained to avoid easily accessible or pre-selected units.

Clear Defect Classification: Ambiguous defect definitions lead to inconsistent inspection results.

Inspector Integrity: The inspector must be objective and follow the defined procedure.

5. Focus on End-of-Line Inspection: AQL is typically used for final inspection. It doesn’t prevent defects from occurring in the first place. It should be part of a broader quality management system.

Importers new to AQL sampling can sometimes make mistakes that undermine its effectiveness:

1. Choosing Inappropriate AQL Levels: Setting AQLs too strict (leading to unnecessary rejections and higher costs) or too lenient (allowing too many defects through). This should be based on product risk and market.

2. Using an Incorrect Lot Size: If the factory under-reports the lot size, the sample size will be too small, reducing the inspection’s reliability. Always verify the total quantity produced.

3. Vague or Incomplete Defect Classification: If inspectors don’t have a clear, product-specific list of what constitutes critical, major, and minor defects, their judgment will be subjective and inconsistent.

4. Inspector Issues:

Lack of Training: The inspector may not fully understand AQL methodology or your specific product requirements.

Factory Influence: Risk of inspectors being pressured or bribed by the factory (less common with reputable third-party agencies).

Non-Random Sampling: Inspectors taking easily accessible samples rather than truly random ones.

5. Not Acting on Inspection Results: Ignoring a “failed” AQL inspection report and shipping the goods anyway defeats the purpose. Have a clear protocol for how to handle failed inspections.

6. Relying Solely on AQL for All QC: AQL is primarily for final batch inspection. It doesn’t replace the need for good design, supplier vetting, and potentially in-process checks.

7. Misunderstanding “Acceptance”: Thinking that an “accepted” lot is defect-free. Remember, AQL implies an acceptable level of defects.

For businesses, especially SMEs or those new to importing, managing the AQL inspection process from afar can be challenging. This is where a professional reliable China sourcing agent can add significant value.

A sourcing agent can typically assist with:

Defining AQL Standards: Helping you determine appropriate inspection levels and AQL values for your specific products and risk profile.

Creating Defect Lists: Working with you to develop clear, illustrated defect classification lists.

Communicating with Suppliers: Clearly conveying all QC requirements to the factory in their local language.

Coordinating Inspections: Arranging for independent third-party inspectors or using their own qualified staff to conduct AQL inspections.

Interpreting Reports: Analyzing inspection reports and advising you on the best course of action if issues are found.

Troubleshooting: Helping to mediate any disputes with the factory regarding quality problems.

Using a trustworthy China sourcing agent can provide peace of mind and a professional layer of quality management, which is particularly beneficial when navigating complex supply chains like those in China.

Understanding what is AQL sampling and how to effectively use the AQL standard, AQL sampling chart, and AQL sampling table is a fundamental skill for any successful import business. It is a powerful statistical tool that, when applied correctly, provides an objective and cost-effective method for assessing product quality before shipment.

While AQL inspection has its limitations and is not a guarantee of defect-free products, it is an indispensable part of a proactive quality management strategy. By setting clear AQLs, defining defects meticulously, ensuring inspections are conducted properly, and integrating AQL with other QC practices, you can significantly reduce the risk of importing substandard goods, protect your brand reputation, and build a more resilient and profitable import business. Embrace AQL sampling as a key ally in your quest for quality and consistency from your overseas suppliers.