In an era defined by unprecedented connectivity, the world has transformed into a vast, interconnected marketplace. For businesses with ambitions that transcend national borders, understanding and leveraging the global economic landscape is no longer an option—it’s the cornerstone of competitive strategy. At the heart of this global paradigm lies a powerful concept: what is global sourcing. This is not merely about buying goods from another country; it is a strategic business philosophy aimed at identifying, evaluating, contracting with, and managing suppliers from across the globe to acquire goods and services. The objective is to harness the immense potential of the international market to achieve a sustainable competitive advantage. For companies worldwide, this often means turning to manufacturing powerhouses like China, a nation synonymous with production scale, diversity, and cost-effectiveness. A well-executed global sourcing strategy can revolutionize a company’s supply chain, unlocking significant cost savings, fostering innovation, and enhancing product quality. However, navigating this complex terrain requires expertise, diligence, and a deep understanding of both the opportunities and the inherent risks. This comprehensive guide will delve into the intricacies of global sourcing, exploring its profound benefits, the strategic processes involved, and how businesses can effectively leverage this approach to thrive in the modern economy. We will also explore the critical role of a global sourcing partner in demystifying and optimizing this complex but rewarding endeavor.

To truly grasp the concept, it’s essential to understand that global sourcing is a significant evolution from traditional, domestic procurement. It represents a fundamental shift in mindset from tactical purchasing to strategic supply chain management.

At its core, what is global sourcing is the strategic process of scouring the globe to find the most cost-effective and highest-quality sources for goods and services to meet a company’s specific business needs. It is an intentional, proactive, and analytical approach. Unlike international purchasing, which can be a reactive, one-off transaction, global sourcing involves establishing long-term relationships with offshore suppliers to integrate them into a cohesive supply chain.

This strategy requires a holistic view that encompasses a multitude of factors beyond the initial purchase price. A company engaged in global sourcing will meticulously analyze:

Total Cost of Ownership: This includes not just the unit price but also logistics, tariffs, insurance, inventory holding costs, and quality control expenses. The goal is to optimize the total cost, not just the ticket price.

Supplier Capabilities: Evaluating a supplier’s manufacturing capacity, technological prowess, quality management systems, and financial stability is paramount.

Risk Assessment: This involves a thorough analysis of geopolitical stability, currency fluctuations, intellectual property protection, and potential supply chain disruptions.

Innovation Potential: Partnering with suppliers who can contribute to product development, offer new materials, or suggest more efficient manufacturing processes.

A mature global sourcing strategy is deeply integrated with a company’s overall business objectives, whether they are focused on cost leadership, product differentiation, or market agility. The importance of a strategic sourcing partner cannot be overstated in this context, as they provide the on-the-ground expertise to manage these variables effectively. For a deeper understanding of the foundational principles, exploring the topic of Supplier Relationship Management is highly recommended.

The journey from local procurement to a sophisticated global sourcing model is driven by a confluence of technological, economic, and political factors.

Technological Advancements: The rise of the internet, advanced communication platforms, and sophisticated logistics software has made it easier than ever to identify, communicate with, and manage suppliers thousands of miles away.

Globalization of Economies: The reduction of trade barriers, the establishment of free trade agreements, and the integration of emerging economies into the global market have opened up a vast new landscape of sourcing opportunities.

Increased Competition: In nearly every industry, companies face intense pressure to reduce costs and improve quality. Global sourcing provides a powerful lever to achieve these goals and stay ahead of the competition.

Access to Specialized Skills and Resources: Certain countries or regions have developed deep expertise and infrastructure in specific industries. Global sourcing allows companies to tap into these specialized ecosystems, whether it’s for electronics in Shenzhen, textiles in India, or automotive parts in Mexico.

This evolution demands that businesses develop new competencies. They must become adept at cross-cultural communication, international logistics, and global risk management. The role of a sourcing business partner becomes crucial in bridging these knowledge gaps and ensuring a smooth operational flow.

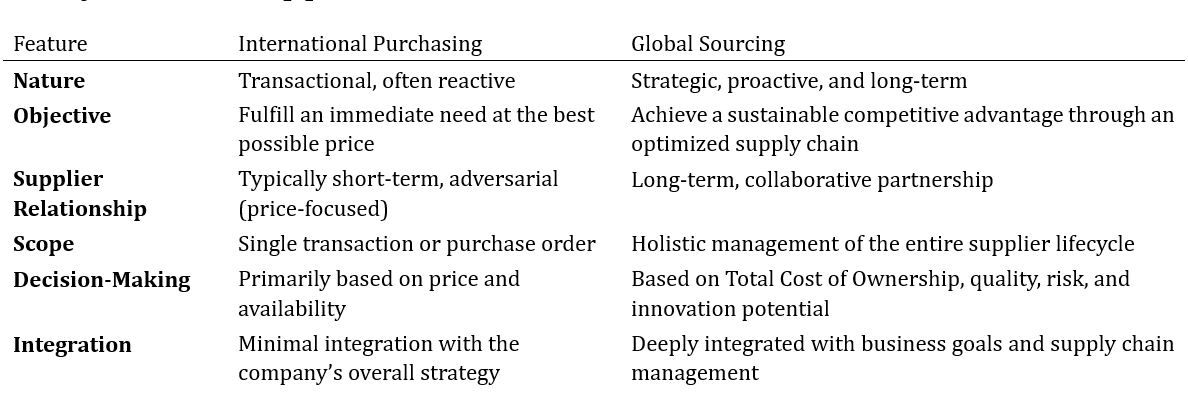

It is critical to distinguish between global sourcing and international purchasing, as the terms are often used interchangeably but represent vastly different approaches.

For instance, a company making a one-time purchase of promotional t-shirts from a Vietnamese vendor is engaging in international purchasing. In contrast, a fashion brand that establishes a long-term, collaborative relationship with a network of factories in China to handle its entire production line—from material sourcing and manufacturing to quality control and logistics—is practicing global sourcing. The latter approach requires a significant investment in relationship building and process management, often facilitated by a dedicated global sourcing partner.

Embracing a global sourcing strategy offers a multitude of benefits that can fundamentally reshape a company’s competitive position and financial performance. These advantages extend far beyond simple cost reduction, touching every aspect of the business from product development to market responsiveness.

This is often the most immediate and compelling driver for companies to adopt global sourcing. The potential for cost savings is multi-faceted and stems from several key economic principles.

Lower Labor Costs: Sourcing from countries with lower wage rates can dramatically reduce the labor component of a product’s cost. For labor-intensive industries like apparel, footwear, and electronics assembly, this can result in savings of 50% or more on manufacturing expenses.

Economies of Scale: Manufacturing hubs like China have developed vast industrial ecosystems that benefit from immense economies of scale. Suppliers can procure raw materials in massive quantities at lower prices, and their highly specialized, high-volume production lines operate with incredible efficiency, leading to a lower per-unit cost.

Reduced Overhead: Suppliers in many sourcing destinations have lower overhead costs related to factory space, utilities, and administrative expenses. These savings are passed on to the buyer.

Favorable Exchange Rates: Strategic sourcing can take advantage of favorable currency exchange rates, further reducing the cost of goods when converted back to the buyer’s home currency.

By strategically sourcing from low-cost countries, businesses can either pass these savings on to consumers to gain market share or reinvest them into other areas of the business, such as research and development or marketing. To maximize these savings, understanding the nuances of shipping is crucial; for instance, knowing why sea freight is cheaper than air freight can be a game-changer for budget planning.

No single country has a monopoly on talent, technology, or resources. Global sourcing opens the door to a worldwide pool of suppliers, each with unique capabilities and specializations.

Specialized Manufacturing Expertise: Certain regions are world-renowned for their expertise in specific industries. For example, China’s Guangdong province is a global hub for consumer electronics, while Zhejiang is a center for textiles and furniture. Tapping into these established ecosystems provides access to a skilled workforce, experienced engineers, and a network of specialized sub-suppliers that would be impossible to replicate domestically.

Technological Advancement: Competition among suppliers in major manufacturing hubs drives rapid technological adoption. A strategic sourcing partner can connect you with factories that have invested in the latest manufacturing technologies, such as advanced robotics, CNC machining, and automated quality control systems, often far beyond what a domestic supplier might offer at a comparable price.

Increased Capacity and Scalability: When a business experiences rapid growth, domestic suppliers may struggle to keep up. Global sourcing provides access to manufacturers with massive production capacities, allowing businesses to scale their operations quickly and efficiently without being constrained by the limitations of their local market.

Contrary to outdated beliefs, sourcing from low-cost countries does not have to mean sacrificing quality. In fact, a strategic global sourcing program can lead to significant improvements in product quality and innovation.

Access to World-Class Quality Management: Many top-tier suppliers in countries like China have implemented rigorous quality management systems, such as ISO 9001, Six Sigma, and Lean Manufacturing. They have dedicated quality control departments and invest heavily in testing equipment to meet the stringent standards of their international clients.

Material and Component Innovation: A global supply base provides access to a wider variety of raw materials and components, some of which may not be available or affordable domestically. Suppliers can often recommend alternative materials that improve performance or reduce cost.

Collaborative Product Development: Treating suppliers as partners fosters an environment of collaboration. A good sourcing business partner can facilitate a process where the supplier’s engineering team works closely with your designers to optimize a product for manufacturability. This collaborative process can lead to better product design, reduced defects, and faster time-to-market. Understanding the difference between OEM and ODM manufacturing is also key to leveraging supplier innovation.

In today’s fast-paced consumer environment, speed is a critical competitive weapon. A well-managed global sourcing strategy can help businesses become more agile and responsive to market changes.

Shorter Product Development Cycles: By leveraging the supplier’s expertise and rapid prototyping capabilities, companies can significantly shorten the time it takes to go from concept to finished product. Many Chinese suppliers, for example, can produce molds and first samples in a fraction of the time it would take in North America or Europe.

Flexible Production: A diverse supplier base allows for greater flexibility. If one supplier is facing a production bottleneck, a company with a well-developed network can quickly shift production to another qualified partner, minimizing delays.

Market Responsiveness: Global sourcing allows companies to quickly launch new products or variations in response to emerging trends. The ability to rapidly test new ideas in the market without massive upfront investment in domestic tooling and manufacturing provides a significant competitive advantage. This agility is what allows many e-commerce brands to stay ahead of the curve.

Relying on a single domestic source for critical components creates significant risk. A disruption at that one supplier—whether from a fire, a labor strike, or a financial issue—can bring your entire business to a halt.

Geographic Diversification: Sourcing from different countries or even different regions within a single large country like China mitigates the risk of localized disruptions. A natural disaster or a regional lockdown in one area is less likely to impact your entire supply chain if you have alternative suppliers in other regions. This is the core idea behind the China +1 supply chain strategy.

Reduced Supplier Dependence: Having multiple qualified suppliers for key products reduces your dependence on any single partner. This not only mitigates risk but also improves your negotiating leverage.

Building Resilience: A diversified global supply chain is inherently more resilient. It can better withstand shocks and adapt to changing geopolitical and economic conditions. The COVID-19 pandemic highlighted the critical importance of supply chain resilience, and companies with diversified global sourcing networks were generally better able to navigate the disruptions than those who were single-sourced. A robust approach to risk management in sourcing is a hallmark of a mature global sourcing strategy.

Successfully implementing a global sourcing strategy is not a simple task. It requires a systematic, well-defined process that covers everything from initial market research to ongoing supplier management. A disciplined approach is essential to maximize the benefits while minimizing the risks. This process can be broken down into several key phases, each requiring careful planning and execution.

This foundational phase is about setting the stage for success. Before you even think about contacting a supplier, you must do your homework and align your sourcing strategy with your business goals.

Define Objectives and Specifications: What are you trying to achieve? Is the primary goal cost reduction, access to new technology, or increased production capacity? Clearly define your objectives. Simultaneously, develop a detailed product specification sheet. This document should include all technical drawings, material requirements, quality standards, packaging instructions, and target costs. The more detailed your specifications, the easier it will be to find and evaluate qualified suppliers.

Market and Country Analysis: Not all countries are created equal when it comes to manufacturing. Conduct a thorough analysis to determine the best country or region for your specific product. Factors to consider include:

- Manufacturing Capabilities: Does the country have a strong industrial base for your product category?

- Labor Costs and Skills: What are the prevailing wage rates, and is there a skilled workforce available?

- Infrastructure: How developed are the ports, roads, and communication networks?

- Trade Policies and Tariffs: Are there any free trade agreements in place? What are the import duties and taxes?

- Political and Economic Stability: What is the level of geopolitical risk? For many product categories, an introduction to key manufacturing hubs of China can provide a valuable starting point for this analysis.

Develop a Sourcing Plan: Based on your objectives and research, create a formal sourcing plan. This plan should outline the project timeline, budget, key milestones, and the roles and responsibilities of your team members. It should also define the criteria you will use to evaluate and select suppliers.

This is the search and discovery phase. The goal is to cast a wide net initially and then systematically narrow down the field to a shortlist of highly qualified potential partners.

Supplier Discovery Channels: There are several ways to find potential suppliers:

- Online B2B Marketplaces: Platforms like Alibaba, Global Sources, and Made-in-China.com are popular starting points, offering access to millions of supplier profiles.

- Trade Shows: Attending major industry trade shows allows you to meet suppliers face-to-face, examine product samples, and build initial relationships.

- Industry Associations and Referrals: Networking within your industry can often lead to referrals for trusted suppliers.

- Hiring a Global Sourcing Partner: This is often the most efficient and secure method. A professional sourcing business partner like Maple Sourcing has an existing, pre-vetted network of reliable suppliers, saving you significant time and reducing the risk of working with unqualified factories. They can provide a curated list of potential suppliers that perfectly match your requirements.

Initial Vetting (Request for Information - RFI): Once you have a long list of potential suppliers, send out a formal RFI. This document should request basic information about the company, such as their size, history, production capacity, key customers, and quality certifications (e.g., ISO 9001). This initial screening will help you weed out suppliers who are clearly not a good fit.

Detailed Evaluation (Request for Quotation - RFQ): For the suppliers that pass the RFI stage, send out a more detailed RFQ. This package should include your full product specification sheet and request detailed pricing based on different order volumes, as well as information on tooling costs, sample costs, and production lead times. The quality of the supplier’s response—its professionalism, clarity, and attention to detail—is a valuable indicator of their capabilities.

Supplier Audits: For your top two or three candidates, a physical factory audit is non-negotiable. This is the only way to verify the claims they have made and to get a true sense of their operations. The audit should be conducted by an experienced professional and cover:

- Quality Management Systems: Do they have documented processes for quality control?

- Production Capabilities: Is their equipment well-maintained? Are their facilities clean and organized?

- Social Compliance: Do they adhere to ethical labor practices?

- Financial Stability: Are they a viable, long-term partner? Many importers find that relying on a trusted partner for why China factory audits are key to your success is the most reliable way to get an unbiased assessment.

With a qualified supplier selected, the next step is to finalize the terms of your partnership and formalize it in a legally binding agreement.

Strategic Negotiation: Negotiation is about more than just haggling over the price per unit. It’s about creating a mutually beneficial agreement that covers all aspects of your relationship. Key negotiation points include:

- Price: Based on volume, with clear terms for future price adjustments.

- Payment Terms: A typical structure is 30% upfront to cover materials and 70% upon completion and successful final inspection. Avoid paying 100% upfront under any circumstances.

- Incoterms: Define the shipping terms (e.g., FOB, EXW) to clarify who is responsible for logistics costs and risks at each stage.

- Production Lead Time: Agree on a realistic timeline from order placement to shipment.

- Intellectual Property (IP) Protection: Ensure it is crystal clear that you own all IP related to your product.

Drafting a Comprehensive Contract: Your purchase agreement is your most important legal protection. It should be drafted by a lawyer with experience in international trade law and should be bilingual (English and Chinese). A robust contract will include:

- Detailed product specifications and quality standards.

- Clear definitions of defects and acceptance criteria.

- Penalties for delays or quality failures.

- Clauses on IP ownership and confidentiality.

- A clear process for dispute resolution. It’s also wise to implement a separate NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreement to further protect your product idea when you outsource from China.

Once the contract is signed and the purchase order is placed, the focus shifts to managing production and getting your goods from the factory to your warehouse.

Production Monitoring: Don’t just wait for the lead time to be over. Maintain regular communication with your supplier throughout the production process. A good global sourcing partner will have staff on the ground to monitor progress, identify potential delays early, and ensure everything is on track.

Quality Control Inspections: A multi-stage inspection process is critical. This typically includes:

- Pre-Production Inspection: To verify raw materials and components.

- During Production Inspection: To catch any issues early in the manufacturing process.

- Pre-Shipment Inspection: A final random inspection of finished goods to ensure they meet your quality standards before you make the final payment. Understanding the different types of inspection in production management is fundamental to ensuring product quality.

Logistics and Shipping: Coordinate with a reliable freight forwarder to handle the transportation of your goods. They will manage the booking of cargo space (sea or air), inland transportation, customs clearance at both the port of origin and destination, and final delivery. The choice between FCL and LCL container shipping will depend on the volume of your shipment.

Customs and Compliance: Ensure that your product complies with all the safety standards and import regulations of your target market. Your supplier should provide all necessary documentation, such as test reports and certificates of origin, and your freight forwarder or customs broker will handle the customs declaration process.

Global sourcing is not a one-time event; it’s the beginning of a long-term relationship. Continuously monitoring performance and investing in the relationship is key to sustained success.

Performance Tracking (KPIs): Establish Key Performance Indicators (KPIs) to measure your supplier’s performance objectively. Key metrics include:

- On-Time Delivery Rate: The percentage of orders that arrive on schedule.

- Quality Defect Rate: The percentage of products that fail inspection.

- Cost Variance: How the actual cost compares to the target cost.

- Communication Responsiveness: How quickly and effectively the supplier responds to issues.

Regular Business Reviews: Hold regular review meetings with your key suppliers to discuss performance, address challenges, and plan for the future. This demonstrates your commitment to the partnership and fosters open communication.

Collaborative Improvement: Work with your strategic suppliers to identify opportunities for improvement. This could involve joint process mapping to reduce waste, sharing demand forecasts to improve planning, or collaborating on new product development. The goal is to move beyond a simple buyer-seller dynamic to a true strategic sourcing partner relationship. Investing in effective supplier relationship management is what separates the most successful importers from the rest.

While the benefits of global sourcing are immense, it is not without its challenges. A naive or poorly executed sourcing strategy can lead to costly mistakes, including supply chain disruptions, quality issues, and hidden costs that erode any potential savings. Acknowledging and proactively managing these challenges is a critical component of a successful global sourcing program. A seasoned global sourcing partner is invaluable in helping businesses navigate these complexities.

Effective communication is the lifeblood of any successful business relationship. When dealing with suppliers in different countries, this becomes significantly more complex.

Language Differences: While many international sales representatives speak English, misunderstandings can still easily occur, particularly with technical specifications. Nuances can be lost in translation, leading to errors in production. A simple word choice can have different implications, and what seems like a clear instruction in English might be ambiguous to a non-native speaker.

Cultural Nuances: Different cultures have distinct approaches to business communication, negotiation, and relationship building. For example, in many Asian cultures, building a personal relationship (“guanxi” in China) is considered a prerequisite for doing business, and a direct, confrontational negotiation style may be seen as disrespectful. Western business culture, in contrast, often prioritizes directness and getting straight to the point. Failing to understand and adapt to these cultural norms can create friction and undermine trust.

Time Zone Differences: A 12-hour time difference can create significant communication delays. An urgent question sent in the afternoon from North America may not get a response until the next day, slowing down decision-making and problem-solving.

Mitigation Strategy: Working with a local sourcing business partner is the most effective way to overcome these barriers. They act as a cultural and linguistic bridge, ensuring your specifications are clearly understood and facilitating smooth, culturally appropriate communication. They operate in the same time zone as the factory, enabling real-time problem-solving.

Maintaining consistent product quality across thousands of miles is one of the biggest anxieties for importers. You cannot simply walk down to the factory floor to check on a production run.

Variation in Standards: What is considered “acceptable quality” can vary significantly between countries and even between different factories. Without explicitly defined and enforced standards, you may receive products that do not meet your expectations or those of your customers.

“Quality Fade”: This is a common phenomenon where a supplier produces perfect initial samples and a high-quality first order, but the quality gradually declines over subsequent production runs as they begin to cut corners to increase their profit margins, perhaps by using slightly inferior materials or rushing production steps.

Difficulty in Enforcement: If a quality issue is only discovered after the goods have been shipped and arrived in your home country, your options are limited and costly. Returning a container of defective goods to China is often not financially feasible, leaving you with a significant loss.

Mitigation Strategy: A robust, multi-stage inspection strategy is non-negotiable. This must be managed by a trusted third party or your own on-the-ground team. Never rely solely on the factory’s internal QC team. A comprehensive plan for inspection and quality control in manufacturing is essential. This includes inspecting raw materials, monitoring the production line, and conducting a thorough final inspection before the final payment is released and the goods are shipped.

Global supply chains are inherently longer and more complex than domestic ones, which introduces more variables and potential points of failure.

Longer Lead Times: The entire process, from placing an order to receiving the goods, can take months. This includes production time (30-60 days is common), ocean freight (30-45 days), and customs clearance. These long lead times require businesses to be much better at demand forecasting and inventory management.

Logistics Complexity: International shipping involves a complex chain of handlers, including factory transport, freight forwarders, shipping lines, ports, customs brokers, and domestic carriers. A delay at any one of these points can have a domino effect on the entire timeline.

Customs and Regulatory Hurdles: Every country has its own set of import regulations, documentation requirements, and customs procedures. An error in paperwork or a product that fails to meet specific compliance standards can lead to significant delays, fines, or even seizure of the shipment by customs authorities. Navigating the complexities of importing goods from China to USA under new tariff policy, for example, requires specialized knowledge.

Mitigation Strategy: Work with experienced freight forwarders and customs brokers. Plan for longer lead times in your inventory management and build in a buffer for potential delays. A strategic sourcing partner can often manage the entire logistics process for you, coordinating with all parties to ensure a smooth flow of goods from the factory to your door.

Protecting your product designs, brand name, and proprietary technology is a major concern when sourcing from overseas, particularly from China.

Counterfeiting: Unscrupulous suppliers may produce and sell unauthorized copies of your product directly to the market, sometimes even before your official launch.

IP Theft: A supplier may take your design or invention and file for a patent in their own country, effectively blocking you from the market or even claiming that you are infringing on “their” IP.

“Supplier Creep”: Your supplier might sell your product to your competitors or through online marketplaces without your permission.

Mitigation Strategy: A multi-layered IP protection strategy is essential. This includes:

1. Legal Agreements: Use a China-enforceable NNN agreement before sharing any sensitive information. Your manufacturing contract should have strong IP protection clauses.

2. Register Your IP: Proactively register your trademarks and patents in the country you are sourcing from. In China, trademark rights are granted on a “first-to-file” basis, so it’s critical to register your brand before someone else does.

3. Smart Supplier Management: For highly sensitive products, consider using multiple factories for different components so that no single supplier has the complete “recipe” for your product.

The global landscape is constantly changing, and these shifts can have a direct impact on your supply chain.

Tariffs and Trade Wars: Sudden changes in trade policy can impose significant tariffs on your imported goods, dramatically increasing your costs and eroding your profit margins.

Ethical Sourcing and Social Compliance: There is growing consumer and regulatory pressure to ensure that products are made in safe and ethical conditions. A scandal involving child labor or unsafe working conditions at one of your suppliers can cause irreparable damage to your brand’s reputation. This is why understanding ethical and sustainable procurement is becoming increasingly important.

Currency Fluctuation: The value of currencies can change, affecting the cost of your goods. A sudden strengthening of the supplier’s currency against your own can lead to unexpected price increases.

Supplier Financial Instability: A key supplier could face bankruptcy, leaving you scrambling to find a new source and potentially disrupting your production for months.

Mitigation Strategy: Stay informed about the global political and economic climate. Diversify your supply base to avoid over-reliance on a single country. Conduct thorough factory audits that include a social compliance component. For financial risk, use structured payment terms that limit your exposure and consider hedging strategies for currency risk.

For many businesses, particularly small and medium-sized enterprises (SMEs), the complexities and challenges outlined in the previous chapter can seem overwhelming. The investment required to build an in-house team of global sourcing experts—with the necessary language skills, cultural understanding, and technical expertise—is substantial. This is where a global sourcing partner becomes an indispensable asset. Acting as an extension of your own business, a sourcing partner provides the on-the-ground presence and specialized knowledge needed to navigate the global sourcing landscape successfully, efficiently, and securely.

A sourcing business partner, often referred to as a sourcing agent or sourcing company, is a firm that manages the entire sourcing and production process on behalf of its clients. They are not simply middlemen who find a factory and then disappear. A true partner is a long-term collaborator who works to understand your business, protect your interests, and optimize your supply chain. Their role encompasses every phase of the sourcing journey, from initial product development to final delivery.

Their value proposition is built on three pillars:

1. Expertise: They possess deep knowledge of the local manufacturing landscape, industry specializations, and the legal and logistical intricacies of international trade.

2. Network: They have an established and pre-vetted network of reliable factories, material suppliers, and logistics providers.

3. Presence: Their physical presence in the sourcing country allows for real-time communication, hands-on management, and immediate problem-solving.

Engaging a strategic sourcing partner like Maple Sourcing transforms the sourcing process from a series of daunting challenges into a streamlined, managed operation.

1. Supplier Identification and Verification:

Instead of sifting through thousands of unverified profiles on B2B websites, a sourcing partner presents you with a curated shortlist of 2-3 highly qualified factories that have already been audited and vetted for their reliability, quality systems, and financial stability. This single step saves countless hours of research and dramatically reduces the risk of choosing the wrong supplier. Understanding how to find trusted wholesale suppliers is part of their core expertise.

2. Product Development and Engineering Support:

A good partner has an engineering team that can review your product design and provide DFM (Design for Manufacturing) feedback. They can work with the factory to optimize your design for efficiency and cost-effectiveness, suggest alternative materials, and manage the prototyping and tooling process to ensure the final product meets your exact specifications.

3. Price and Contract Negotiation:

Leveraging their local market knowledge, language skills, and established relationships, a sourcing partner can negotiate more effectively than an outside buyer. They know the true market rates for materials and labor and can secure better pricing and more favorable payment terms on your behalf. They also manage the creation of a robust, bilingual manufacturing contract that protects your interests.

4. Hands-On Project Management:

The partner acts as your single point of contact, managing all communication with the factory. Their project managers provide regular, consolidated updates on production status, eliminating the need for you to chase down information across different time zones. They proactively manage the production schedule to ensure your deadlines are met.

5. Rigorous Quality Assurance:

This is one of the most critical functions. A sourcing partner deploys their own team of inspectors to the factory to conduct quality control checks at every stage of production. They are your eyes and ears on the factory floor, ensuring that your quality standards are being met long before the products are shipped. This provides a level of security and peace of mind that is impossible to achieve from a distance. A deep dive into choosing third party quality control services highlights the importance of this independent oversight.

6. Logistics and Shipping Coordination:

The partner manages the entire shipping process, from factory pickup to final delivery. They work with their network of trusted freight forwarders to find the most cost-effective and reliable shipping solutions, handle all documentation, and manage the customs clearance process, ensuring a seamless flow of goods.

7. Problem Solving and Crisis Management:

When issues inevitably arise—a production delay, a quality problem, a case of customs hold-up—your partner is on the ground to manage the situation immediately. Their ability to quickly diagnose the problem and implement a solution can be the difference between a minor hiccup and a major disaster.

While any business can benefit from the expertise of a sourcing partner, it becomes particularly critical for:

* Startups and Small Businesses: Companies that lack the resources, experience, or personnel to manage international sourcing in-house.

* Companies Sourcing for the First Time: The learning curve for global sourcing is steep. A partner can help you avoid common and costly “rookie mistakes.”

* Businesses with Complex Products: Products that require tight tolerances, multiple components, or complex assembly benefit greatly from the hands-on oversight a partner provides.

* Companies Looking to Scale: When your order volumes are growing rapidly, a partner can help you manage the transition to larger, more capable factories and ensure a stable supply chain.

* Brands Where Quality is Paramount: For premium brands, ensuring flawless product quality is essential. The rigorous QA processes of a top-tier sourcing partner are a vital investment in brand protection.

The central question to ask is: what is the cost of getting it wrong? The financial and reputational damage from a single bad production run can far exceed the fees paid to a professional sourcing partner. To learn more about how we can help, we encourage you to explore our sourcing services.

In the final analysis, the question for ambitious businesses is not whether to engage in global sourcing, but how to do so strategically and effectively. What is global sourcing is a paradigm shift—a move from the confines of local markets to the boundless opportunities of a globalized economy. It is a powerful engine for growth, innovation, and profitability. The benefits—from substantial cost reductions and access to a world of talent and technology to enhanced product quality and a more resilient supply chain—are too significant to ignore. By leveraging the comparative advantages of different regions around the world, companies can build a formidable competitive edge that is difficult for domestically focused rivals to replicate.

However, the path to successful global sourcing is paved with complexity. Navigating cultural barriers, ensuring consistent quality, managing intricate logistics, and mitigating a host of risks requires a deliberate, informed, and systematic approach. The principles and processes outlined in this guide provide a roadmap for this journey. From meticulous strategic planning and rigorous supplier qualification to diligent performance management and proactive risk mitigation, each step is crucial for building a sourcing operation that is not just profitable, but sustainable.

For many businesses, the key to unlocking the full potential of this strategy lies in collaboration. Partnering with a dedicated global sourcing partner can demystify the process, converting daunting challenges into manageable, streamlined operations. A partner acts as your trusted guide and on-the-ground team, providing the expertise and presence needed to protect your interests and optimize your results.

The world of commerce is undeniably global. The businesses that will lead the future will be those that embrace this reality, building intelligent, agile, and robust supply chains that span the globe. By adopting a strategic approach to global sourcing, you are not just buying products; you are building a foundation for long-term success in the interconnected marketplace of the 21st century.