In the modern marketplace, particularly in the booming world of e-commerce where the digital shelf is infinite and competition is just a click away, the first physical interaction a customer has with a brand is no longer the product itself, but the box it arrives in. This initial moment of contact, the “unboxing,” has evolved from a simple logistical function into a powerful marketing and brand-building opportunity. The front porch has become the new retail shelf, and the shipping box is the new storefront, serving as a tangible ambassador for an otherwise digital brand. Fueled by social media and a rising consumer expectation for personalized and delightful experiences, the unboxing phenomenon has fundamentally shifted the conversation around packaging from a pure cost-center to a critical marketing function. Yet, for many businesses, the decision to invest in custom packaging boxes is fraught with tension, pitting the immediate, tangible expense against a host of long-term, often intangible, benefits. This creates a critical business dilemma: is custom packaging a necessary investment in brand value and customer experience, or is it an unjustifiable cost that eats into profit margins?

The answer is not simple, and it requires a strategic mindset that looks beyond line items on an expense report. It demands a comprehensive analysis that goes far beyond the per-unit price of a box. The true “cost” of packaging includes not only materials and manufacturing but also its impact on the entire supply chain, from the freight shipping cost of getting goods from the factory to the last-mile delivery charge. Similarly, the “value” extends beyond aesthetics to include superior product protection, enhanced brand loyalty, and even logistical efficiencies that can lead to significant savings. This guide will provide a deep and thorough analysis of the cost-versus-value equation of custom packaging boxes, with a special focus on corrugated packaging boxes and the strategic considerations for businesses sourcing their products and packaging from global manufacturing hubs like China.

Before diving into the financial costs, it’s crucial to understand the psychological value that custom packaging creates. In a digital world, the physical delivery of a product is one of the few tangible touchpoints a brand has with its customers. A well-executed unboxing experience leverages this moment to create a lasting emotional connection, turning a simple transaction into a memorable event.

The Endowment Effect: This is a powerful psychological principle where people ascribe more value to things simply because they own them. A premium unboxing experience can kickstart this effect before the customer even uses the product. The care and quality invested in the packaging are transferred to the product itself in the customer’s mind, making them feel they have made a high-value purchase and increasing their satisfaction. A product in a beautifully designed box with a magnetic closure and a custom insert feels more valuable than the exact same product in a plastic bag inside a standard brown box. This effect can be further heightened through personalization; even a simple digitally printed “Thank you, [Customer Name]” on an inner flap can make the experience feel unique and personal, strengthening the sense of ownership and brand affinity, making it feel less like a mass-produced item and more like a gift.

Sensory Experience: Humans are multi-sensory creatures. Custom packaging allows a brand to engage more than just the sense of sight. A generic box is a missed opportunity, engaging only one sense. A custom box, however, can be a symphony for the senses. Consider the tactile feel of a soft-touch lamination that feels like velvet, the satisfyingly deep sound of a well-fitted rigid box lid sliding off, or the crisp rustle of custom-printed tissue paper. Even a subtle, pleasant scent embedded in the packaging can create a rich sensory experience that is far more memorable and impactful than simply seeing a product. This deep sensory engagement creates stronger neurological pathways, literally making the brand more memorable and the experience more pleasurable.

The Peak-End Rule: This well-documented theory of behavioral psychology states that people judge an experience largely based on how they felt at its peak (its most intense point) and at its end. In an e-commerce journey, the “end” is the moment the customer receives and opens the package. A frustrating, difficult-to-open package sealed with excessive tape creates a negative final impression that can sour the entire purchase experience, regardless of how great the product is. Conversely, a delightful, easy, and beautiful unboxing—perhaps with a tear-strip for easy opening and a thoughtful presentation of the contents inside—creates a strong, positive peak-end memory. This positive final touchpoint dramatically increases the likelihood of a repeat purchase and a glowing positive review. Brands that master this create a “delightful finish” that customers remember and talk about.

Investing in custom packaging boxes is, therefore, a direct investment in managing these psychological principles to build a stronger, more resilient, and more beloved brand.

When businesses first explore custom packaging, their primary focus is often the per-unit price. However, this price is the culmination of numerous interconnected factors. Understanding these cost components is the first step in making an informed decision and finding opportunities for optimization.

The material selected is the most significant driver of the base cost.

* Corrugated Cardboard: The undisputed king of e-commerce and shipping packaging. Corrugated cardboard boxes are made by gluing a fluted, wavy sheet of paper between two flat linerboards. The cost is influenced by the paper type. Kraft linerboard, made from virgin wood pulp, is stronger, more durable, and provides a better printing surface. Test linerboard, made from recycled paper, is more cost-effective and environmentally friendly but offers less strength and can have a more mottled appearance. The paper’s weight, measured in grams per square meter (GSM), also directly impacts cost and durability. Specialty coatings, such as water-resistant or anti-static coatings, can also be applied for specific applications, adding to the material cost. The environmental impact of these choices can also be a “cost” to the brand’s reputation if not aligned with customer values, making sustainable, certified materials a worthwhile investment for many brands.

* Paperboard (Folding Cartons): This is a thinner, single-ply paper-based material, often used for the primary retail packaging that you see on a store shelf (e.g., a box for cosmetics or a phone). It is less protective than corrugated but offers a much smoother surface for high-quality printing.

* Rigid Board (Greyboard): For luxury products like high-end electronics, jewelry, or spirits, rigid boxes provide a premium, heavyweight feel. They are constructed from thick, condensed paperboard and are significantly more expensive and labor-intensive to produce, as they are often hand-finished.

Creating a box that is not a standard, off-the-shelf size or shape requires custom tooling, which represents a one-time setup cost.

* Die-Cutting Costs: A “die” is essentially a custom-made cookie cutter for cardboard. It is a wooden board with sharp steel rules embedded in it that are bent into the shape of the flattened box pattern. The process of making a die involves a skilled technician using specialized equipment to precisely bend the steel rules and hammer them into laser-cut slots in the wood. The choice of machine also affects tooling. Flatbed die-cutters press the die onto a stationary sheet, allowing for very complex shapes but at a slower pace, making them ideal for shorter runs. Rotary die-cutters use a cylindrical die and cut the cardboard as it rolls through at high speed, making them efficient for high-volume runs of simpler shapes. The cost of creating a custom die can range from a few hundred to several thousand dollars, depending on its size and complexity. This is a one-time cost (a Non-Recurring Expense, or NRE), but it is a significant upfront investment for a new box design.

* Printing Plate Costs: For high-volume printing methods like flexography and offset lithography, custom printing plates must be created for each color in the design. Like the cutting die, this is another NRE. The more colors you have, the more plates are needed, and the higher the initial setup cost.

The visual appeal of a box is driven by the printing and finishing, and each additional process adds to the per-unit cost.

Printing Methods & Color Management:

- Flexographic Printing: This method uses flexible rubber-like plates and is akin to a sophisticated stamping process. It is very fast and cost-effective for high volumes but is best suited for simpler designs with one or two colors (e.g., using Pantone spot colors). It is the standard for printing logos on standard corrugated packaging boxes.

- Offset Lithography: This method produces very high-quality, photo-realistic images using the CMYK color model. The design is transferred from a metal plate to a rubber blanket and then onto the packaging material. It has high setup costs (for the plates) but becomes very cost-effective at very high volumes.

- Digital Printing: This is like using a giant inkjet or laser printer. It requires no custom plates, making it ideal for low-volume runs, prototypes, or designs with many colors and complex graphics. It’s also the only method that allows for variable data printing (e.g., printing a unique serial number or customer name on each box).

- Color Management: A critical cost and quality factor is the choice between CMYK and Pantone (PMS) spot colors. CMYK is a four-color process that can create a wide spectrum of colors, but the final color can vary slightly from run to run. PMS colors are pre-mixed inks that produce a single, specific color with perfect consistency every time. Using PMS colors is essential for brand consistency but adds cost as each PMS color requires its own printing plate. The pre-press work to ensure artwork has the correct color profiles (e.g., GRACol for North American offset) and high-resolution images is a hidden but crucial step; errors here can force costly reprints.

Finishes and Embellishments: These are the final touches that can elevate a box from a container to a luxury experience.

- Lamination: A thin plastic film (matte, gloss, or even “soft-touch” for a velvety feel) is applied to the box, providing a premium texture and protection against scuffs and moisture.

- Spot UV: A glossy, clear coating is applied to specific areas of the design (like a logo) to make it pop against a matte background.

- Foil Stamping: A metallic foil (gold, silver, etc.) is applied to the box using heat and pressure, creating a high-end, reflective look.

- Embossing/Debossing: The process of pressing a die into the surface of the box to create a raised (embossed) or indented (debossed) effect.

This is perhaps the most critical cost factor for any business to understand. The setup costs for a custom manufacturing run (creating the die and printing plates, setting up the machines) are the same whether you are producing 500 boxes or 50,000 boxes. When that fixed cost is spread over a larger number of units, the per-unit price plummets.

* 500 units: Setup cost ($1,000) + Run cost ($1.50/unit * 500 = $750) = $1,750 total. Per-unit cost: $3.50.

* 5,000 units: Setup cost ($1,000) + Run cost ($0.80/unit * 5,000 = $4,000) = $5,000 total. Per-unit cost: $1.00.

* 50,000 units: Setup cost ($1,000) + Run cost ($0.50/unit * 50,000 = $25,000) = $26,000 total. Per-unit cost: $0.52. This dynamic often creates a challenge for startups and small businesses that cannot meet the high Minimum Order Quantities (MOQs) required to achieve a low per-unit cost.

While the costs of custom packaging are relatively easy to calculate, the value it generates is more complex, touching everything from marketing and brand loyalty to operational efficiency. This value is the return on the initial investment.

In the age of social media, the “unboxing experience” has become a powerful marketing tool. A beautifully designed custom box with thoughtful details turns the simple act of opening a package into a memorable event.

* First Impression and Perceived Value: Custom packaging immediately signals that the product inside is of high quality and that the brand is detail-oriented. This elevates the perceived value of the product before the customer even touches it. A custom insert, made from die-cut corrugated or foam, that presents the product securely and beautifully when the box is opened, further enhances this premium feel. Including “discoverable” elements, like a clever message printed on an inner flap or a custom-printed tissue paper, adds layers to the experience and makes the customer feel like they’ve found a hidden gem.

* Brand Storytelling: The box is a blank canvas to tell your brand’s story. You can use custom graphics, colors, and text to communicate your brand’s mission, values, and personality. This transforms a transactional delivery into a relational brand experience.

* User-Generated Content and LTV: Customers who have a delightful unboxing experience are far more likely to share photos or videos on social media. This is essentially free marketing and a powerful form of social proof that can drive new sales. Furthermore, a positive initial experience is a key driver of customer loyalty and repeat purchases, increasing the overall Customer Lifetime Value (LTV).

One of the most direct and quantifiable value propositions of custom packaging is its ability to protect the product.

* The Problem with Standard Boxes: Using a standard, off-the-shelf box that is too large for the product requires the use of void fill materials like bubble wrap or air pillows. During the violent journey of shipping—where packages are dropped, thrown, and vibrated—the product can still shift inside the box and get damaged.

* The Custom Solution: Custom packaging boxes are designed to the exact dimensions of the product. Custom-designed inserts immobilize the product, providing vastly superior protection.

* The ROI in Action (Example): Imagine a company selling glass bottles of olive oil. Using a standard box with bubble wrap, they experience a 5% damage rate. Each damaged bottle costs them $20 (product cost) + $10 (shipping) + $5 (customer service time) = $35 per incident. For every 1,000 units shipped, they lose 50 units, costing them $1,750. By investing in a custom box with a corrugated insert that drops the damage rate to 0.5%, they now only lose 5 units, for a cost of $175. The saving is $1,575 per 1,000 units shipped. This saving can quickly pay for the upfront tooling costs of the custom box.

This is where custom packaging can generate surprising and substantial value, directly impacting the bottom line.

* The Tyranny of Dimensional Weight (DIM Weight): Shipping carriers like FedEx, UPS, and DHL, as well as LTL freight carriers, do not just charge based on the actual weight of a package. They charge based on DIM weight, which is a calculation of the package’s volume. The formula is typically (Length x Width x Height) / 139 for domestic shipments. The carrier charges for whichever is greater: the actual weight or the DIM weight.

Case Study: Company X’s Journey to Profitability:

* The Product: Company X sells a lightweight electronic device. The product itself weighs 1 lb and has dimensions of 8” x 6” x 2”.

* Scenario 1: The Standard Box. They use a standard 10” x 8” x 4” box. The volume is 320 cubic inches. The DIM weight is 320 / 139 = 2.3 lbs, which rounds up to a 3 lb shipping charge. The cost to ship this 3 lb package is $12.

* Scenario 2: The Custom Box. They invest in a custom packaging box with dimensions 8.5” x 6.5” x 2.5”. The volume is 138 cubic inches. The DIM weight is 138 / 139 = 0.99 lbs. The carrier now bills based on the actual weight of 1 lb. The cost to ship this 1 lb package is only $8.

* Per-Unit Savings: The company saves $4 on every single unit shipped. If they ship 20,000 units a year, this translates into $80,000 in direct annual savings.

* Pallet-Level Savings: The standard box is 320 cubic inches. The custom box is 138 cubic inches. On a standard 40”x48” pallet stacked 48” high, they can fit approximately 288 standard boxes, but they can fit approximately 670 custom boxes. They can ship more than twice the number of units on a single pallet, dramatically cutting their LTL freight shipping cost.

* Container-Level Savings: This effect is magnified at the container level. A 40-foot shipping container has about 2,390 cubic feet of space. By using a box that is less than half the volume, Company X can fit more than double the number of units in a single container. This could cut their per-unit inbound shipping container price from the factory in China in half, from $1.00/unit to less than $0.50/unit. This efficiency also reduces the company’s carbon footprint, a value point that can be used in marketing.

Since corrugated packaging boxes are the most common type used for shipping, it’s worth understanding them in more detail.

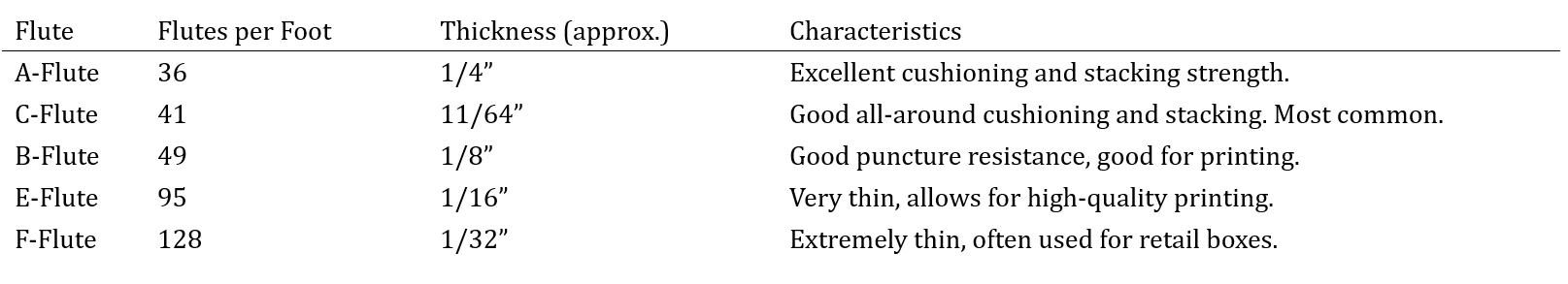

The “flute” refers to the size of the waves in the medium. Different flute profiles offer different properties.

Edge Crush Test (ECT): This measures the stacking strength of the board in pounds per linear inch. An ECT rating of 32 lbs/in is a common standard. This is the most important metric for e-commerce companies who need to know how high their boxes can be stacked on pallets in a warehouse without crushing.

Mullen Test (Bursting Test): This older test measures the force required to burst or puncture the face of the board. It is more relevant for protecting against rough individual package handling.

Beyond the box itself, custom corrugated inserts are a key part of a protective packaging system. These can be simple partitions to separate items, or complex, folded structures that perfectly cradle an irregularly shaped product. They are designed from the same material as the box and are die-cut to shape, providing a cost-effective and recyclable alternative to foam.

While graphics and printing get a lot of attention, the structural design of a box is equally, if not more, important. A well-designed structure can reduce material usage, improve strength, and enhance the unboxing experience.

Common Box Styles:

- Regular Slotted Container (RSC): The most common box style. All flaps are the same length, and the two outer flaps meet in the middle. It’s efficient to manufacture but requires tape to seal. Best for high-volume, automated packing lines.

- Full Overlap (FOL): The outer flaps fully overlap, providing extra thickness and strength on the top and bottom. This is ideal for heavy items and long, thin boxes (like for mirrors) where the flaps might otherwise sag.

- Roll End Tuck Top (RETT): Often called a “mailer box,” this style is cut from a single piece of corrugated and folds together to form a secure box with a lid that tucks in. It requires no tape, offers a fantastic presentation for the unboxing experience, and is very durable, making it a favorite for subscription boxes and e-commerce shipments.

The Structural Design Process: The process begins with a product sample. A structural designer will analyze the product’s size, weight, and fragility. Using specialized CAD software, they will design a box and internal inserts. This digital file is then sent to a cutting table (a plotter with a knife), which automatically cuts a prototype from a sheet of corrugated. This allows the designer and client to test the structure and fit before investing in the expensive cutting die.

For many businesses, sourcing their product and its packaging from the same region is a highly efficient strategy. China’s mature manufacturing ecosystem offers immense opportunities for cost-effective, high-quality custom packaging.

A critical part of sourcing packaging from overseas is the sampling process. This is a multi-step validation that should never be skipped.

1. The “White Sample”: Before any printing plates are made, request an unprinted sample of the box, cut from the correct material. The purpose of this sample is purely to test the structure, fit, and strength. You can assemble it and place your product inside to ensure a perfect fit. This is a low-cost way to validate the expensive die-line.

2. The “Digitally Printed Sample”: Once the structure is approved, provide your artwork. For a small fee, most suppliers can produce a one-off, digitally printed sample. This allows you to check the colors, graphic placement, and overall look of the final design before you invest thousands of dollars in printing plates and dies.

3. The Pre-Production Sample (PPS) or “Golden Sample”: This is the final approval step. The supplier will produce the first box off the actual production line using the final tooling. You must approve this “golden sample” before they are allowed to proceed with the full production run. This sample is then kept by you and the factory’s QC team as the benchmark against which all production units are compared.

Navigating this multi-stage sampling and production process from thousands of miles away is challenging. A sourcing partner is invaluable.

* Vet Suppliers: They can identify packaging suppliers with the right equipment and a proven track record of quality.

* Manage Communication: They handle all technical communication regarding die-lines, artwork, and color matching (using Pantone color codes) to ensure nothing is lost in translation.

* On-Site QC: They can perform on-site quality control during the production run, checking for print defects (hickeys, ghosting), print registration, color accuracy (with a spectrophotometer), and correct assembly. This is a crucial part of inspection and quality control in manufacturing.

* Consolidate Shipments: They coordinate with your product manufacturer to have the products and packaging meet at the same place for final assembly and packing, streamlining the entire process before loading into a shipping container.

In the end, the debate over the cost versus the value of custom packaging boxes is a question of strategic perspective. Viewing packaging as merely a cost to be minimized leads to the use of standard brown corrugated cardboard boxes that do little more than get the product from A to B. While this may seem efficient on a spreadsheet, it ignores the hidden costs of shipping damage, the missed marketing opportunities of a memorable unboxing experience, and the logistical inefficiencies of shipping empty space around the world. This short-sighted view treats the customer’s first physical touchpoint with the brand as an afterthought, a dangerous proposition in a competitive market.

Viewing packaging as a strategic investment, however, opens up a world of value. It becomes a tool to protect your product, enhance your brand, delight your customers, and optimize your supply chain. It is a tangible manifestation of your brand’s promise and a critical component of the overall customer experience. From the psychological benefits of a delightful unboxing to the hard-dollar savings of optimized logistics, the returns are multi-faceted and significant. From reducing your freight shipping cost to turning customers into brand ambassadors, the right packaging pays for itself many times over.

The initial expense is not a cost; it is an investment in a superior customer experience and a more efficient, profitable business. For any company serious about building a lasting brand in today’s competitive market, the value of custom packaging is undeniable. To navigate the complexities of sourcing high-quality, cost-effective packaging, it is wise to partner with experts who can guide you through every step of the process, a core part of our sourcing services.