In the hyper-competitive landscape of global commerce, the efficiency and resilience of a company’s supply chain are no longer just operational details—they are foundational pillars of success. For businesses engaged in international trade, particularly those sourcing products from manufacturing hubs like China, mastering logistics is paramount. The journey of a product from a factory floor to a customer’s doorstep is fraught with complexity, involving transportation, warehousing, customs clearance, and final-mile delivery. Managing this intricate dance requires significant expertise, resources, and technology. This is where logistics partners come into play, offering specialized services that allow businesses to focus on their core competencies.

The two most prominent models for outsourcing logistics are Third-Party Logistics (3PL) and Fourth-Party Logistics (4PL). While often used interchangeably, they represent fundamentally different approaches to supply chain management. Choosing between 3PL 4PL logistics is a strategic decision that can have a profound impact on a company’s operational efficiency, cost structure, and ability to scale. A third party logistics 3PL provider might be perfect for one business, while a 4PL partnership could be the transformative solution another needs. This comprehensive guide will delve deep into the nuances of both models, exploring their services, benefits, and limitations. We will provide a detailed comparison and analyze how each model fits within the specific context of sourcing from China, helping you determine which strategic approach will best serve your business needs and drive your growth.

The most common form of logistics outsourcing, the 3PL model, has been a cornerstone of supply chain management for decades. It represents a tactical and operational approach where a business outsources specific logistics functions to an external company. Understanding the depth and breadth of 3PL solutions is the first step in evaluating their suitability for your operations.

A Third-Party Logistics (3PL) provider offers outsourced logistics services to client companies. In this model, the business retains overall management and strategic oversight of its supply chain but delegates the day-to-day execution of logistics tasks. Think of a 3PL as a “doer”—a specialized contractor hired to perform specific functions like transportation, warehousing, and order fulfillment. The relationship can range from a simple, transactional agreement for a single service to a more integrated partnership covering multiple functions.

Critically, the client company maintains direct communication and contractual relationships with the 3PL. If a business uses multiple 3PLs for different regions or functions (e.g., one for North American warehousing and another for European freight), it is the client’s responsibility to manage and coordinate these disparate partners. The 3PL executes the plan; the client creates and manages the plan. This distinction is vital; the client company acts as the strategic brain of the supply chain, while the 3PL acts as the muscle, carrying out the necessary physical and administrative tasks.

The appeal of the 3PL model lies in the extensive menu of services that providers offer. Businesses can pick and choose the specific functions they need to outsource, creating a customized logistics solution. Leading 3PL fulfillment companies and service providers typically offer a wide array of options, which can be bundled or contracted individually.

This is often the most fundamental 3PL logistics service. It involves the physical movement of goods from origin to destination.

- Freight Forwarding: This is more than just booking. A 3PL will arrange the entire journey, which could involve a truck from the factory to the port, ocean freight to the destination country, and another truck to the warehouse. They handle all the documentation and coordination between these different legs of the journey.

- Carrier Management: 3PLs have established relationships and significant volume with multiple carriers. This allows them to negotiate preferential rates and secure capacity, especially during peak seasons when it might be difficult for a smaller company to get space on a vessel or aircraft.

- Mode Optimization: A 3PL will analyze a client’s needs based on cost, speed, and volume to recommend the best transport mode. This could mean using air freight for high-value, time-sensitive goods, or ocean freight for bulk, less urgent shipments. For importers, understanding these trade-offs is crucial, which is why knowing why sea freight is cheaper than air freight is a key piece of strategic knowledge. They can also manage intermodal transport, combining rail and truck for cost-effective domestic distribution.

- International Shipping and Consolidation: For smaller shipments that don’t fill a whole container (Less-than-Container Load or LCL), a 3PL can consolidate freight from multiple clients into a single container, significantly reducing shipping costs for each client. They also manage the complexities of Full-Container Load (FCL) shipping, which you can learn more about in this guide to the difference between FCL and LCL.

For businesses that sell physical products, warehousing is a critical function that 3PLs have perfected.

- Storage and Distribution: 3PLs operate vast warehouse networks, allowing clients to store products closer to their end customers, reducing shipping times and costs. They offer shared (multi-client) warehousing, which is cost-effective for businesses with fluctuating inventory, or dedicated warehousing for larger clients with specific needs.

- Inventory Management: Using sophisticated Warehouse Management Systems (WMS), 3PLs track every item with precision. They manage stock rotation using methods like First-In, First-Out (FIFO) or Last-In, First-Out (LIFO) to prevent spoilage or obsolescence, a topic detailed in our article on the advantages and disadvantages of LIFO and FIFO. They provide clients with real-time visibility into stock levels, helping to prevent stockouts or overstocking.

- Value-Added Services: This is a major area of growth for 3PLs. Services can include product assembly, kitting (bundling a shampoo and conditioner into a single retail unit, for example), custom labeling, price tagging, and creating point-of-sale displays. These services help customize products just before they are shipped to retailers or customers.

This is a crucial service for e-commerce and direct-to-consumer businesses, and a core competency of many 3PL fulfillment companies.

- Pick, Pack, and Ship: When an order is received, the WMS directs a warehouse worker to the precise location of the item(s). The items are picked, scanned for accuracy, packed securely in appropriate packaging (with dunnage to prevent damage), and labeled for shipment. The process is optimized for speed and accuracy.

- E-commerce Integration: Modern 3PLs offer seamless, API-based integrations with major e-commerce platforms (like Shopify, BigCommerce, Amazon Seller Central) and marketplaces. This allows orders to flow directly from the sales channel to the 3PL’s WMS without any manual data entry, reducing errors and speeding up fulfillment.

- Shipping and Distribution: After packing, the 3PL’s system will often “rate shop” among various carriers (like FedEx, UPS, DHL, and postal services) to find the cheapest or fastest shipping option that meets the customer’s selected delivery timeframe.

Handling returns efficiently is vital for customer satisfaction and profitability.

- Returns Processing: 3PLs establish a clear process for customers to return products. Upon receipt at the warehouse, each return is scanned and recorded.

- Inspection and Disposition: The 3PL inspects the returned item based on client-defined rules. Is it in new, sellable condition? Can it be refurbished? Or should it be liquidated or disposed of? This systematic process helps recover maximum value from returned goods.

- Customer Communication: The 3PL’s system can trigger communications to the client’s e-commerce platform to issue a refund or send a replacement, closing the loop with the customer.

Significant Cost Reduction: 3PLs achieve economies of scale that are unattainable for most individual companies. Their consolidated shipping volumes command lower rates from carriers, and their shared warehouse space spreads fixed costs over many clients.

Focus on Core Business Competencies: By outsourcing the complex and capital-intensive functions of logistics, companies can redirect their financial and human resources toward innovation, product design, marketing, and customer service.

Access to Expertise and Technology: Clients gain immediate access to a 3PL’s established infrastructure, technology (WMS, TMS), and a workforce trained in logistics best practices, all without the hefty upfront investment.

Enhanced Scalability and Flexibility: A 3PL partner allows a business to be agile. During peak season, a company can use more warehouse space and labor, and then scale back down during slower periods, converting fixed costs into variable costs.

Limited Strategic Oversight: A 3PL is a tactical provider. They are focused on efficiently executing the tasks they are given. They do not typically provide proactive, strategic advice on how to optimize your entire supply chain network.

Coordination Complexity: The responsibility for managing the “big picture” remains with the client. If you use a 3PL for warehousing in the US, a different one for Canada, and a separate freight forwarder for ocean transport, you become the central coordinator responsible for making sure they all work together.

Lack of End-to-End Visibility: Data is often siloed within each 3PL’s system. While you can see your inventory in a specific 3PL’s warehouse, you may not have a single, unified view of all your inventory in transit and across all locations.

Potential Loss of Direct Control: Your 3PL’s performance is a direct reflection of your brand. A late shipment or a packing error by the 3PL is, in the customer’s eyes, a failure by your company. This requires a high degree of trust.

A third party logistics 3PL model is often the ideal solution for:

- Small to Medium-Sized Businesses (SMBs): Companies that need access to professional logistics capabilities without the high cost of building them in-house.

- Startups and E-commerce Brands: Businesses that require the ability to scale fulfillment operations rapidly as their sales volume grows.

- Companies Entering New Markets: A local 3PL can provide the necessary infrastructure and market knowledge to expand into a new geographic region without establishing a physical presence.

- Businesses That Want to Retain Strategic Control: Companies with a strong internal supply chain team that wants to maintain control over strategy while outsourcing the execution.

As supply chains have grown more complex and global, a new model has emerged to address the strategic limitations of the 3PL approach. The Fourth-Party Logistics (4PL) model, also known as a Lead Logistics Provider (LLP), represents a fundamental shift from outsourcing tasks to outsourcing the management of the entire supply chain.

A 4PL is a strategic partner that acts as a single point of contact and accountability for a company’s entire supply chain. A 4PL provider manages the logistics process on a much broader scale. They are supply chain integrators and optimizers. Their role is to design, build, and run a comprehensive supply chain solution for their client.

A key distinction is that 4PLs are often not asset-based. While a 3PL might own its own trucks and warehouses, a 4PL’s primary assets are its people, technology, and expertise. The 4PL’s job is to manage a network of other service providers—including 3PLs, freight forwarders, carriers, and customs agents—to deliver a seamless and optimized solution. They act as the single interface between the client and all these different logistics partners, orchestrating the entire network like a general contractor building a house.

A 4PL’s services are strategic and integrative, going far beyond the operational tasks of a 3PL.

- Supply Chain Strategy and Design: A 4PL begins by conducting a deep analysis of the client’s business, market, and goals. They then design an optimal supply chain network, determining the best locations for warehouses, the most efficient transportation lanes, and the right inventory policies. This can include complex strategies like developing a China +1 supply chain strategy to mitigate geopolitical risks.

- Logistics Provider Management: The 4PL takes on the entire burden of sourcing, vetting, negotiating with, and managing all logistics providers. They use their industry knowledge and leverage to select the best-performing and most cost-effective partners for each specific function, holding them accountable to strict KPIs.

- Technology and Data Integration: This is the heart of the 4PL model. The 4PL provides a single, integrated technology platform (often called a “control tower”) that gives the client end-to-end visibility across the entire supply chain. This platform consolidates data from all partners, enabling advanced analytics, real-time tracking, and comprehensive reporting.

- Business Process Management and Optimization: 4PLs take ownership of managing and continuously improving key supply chain processes. This includes demand planning, inventory optimization, order management, and freight audit and payment. Their goal is not just to run the supply chain but to make it leaner, faster, and more cost-effective over time.

- Consulting and Analytics: A 4PL acts as a strategic advisor. They provide predictive analytics to forecast future disruptions, prescriptive analytics to recommend actions, and ongoing consulting to help the client adapt to changing market conditions.

Single Point of Contact and Accountability: This is the most significant advantage. The client has one partner to manage, one invoice to pay, and one entity to hold accountable for the performance of the entire supply chain. This dramatically simplifies management and communication.

Unparalleled Visibility and Data-Driven Insights: The integrated technology platform provides a “single source of truth,” offering a holistic view of inventory, shipments, and performance. This allows for better forecasting, proactive disruption management, and truly strategic decision-making.

Objective, Strategic Optimization: Because 4PLs are typically non-asset-based, they are neutral. They can select the best possible 3PL or carrier for a specific job based purely on performance and cost, without being biased toward using their own assets. Their success is directly tied to the success and efficiency of the client’s supply chain.

Reduced Operational Burden: The 4PL takes on the full weight of managing logistics, freeing the client to focus on its highest-value activities and strategic growth initiatives.

Significant Trust and Transparency Required: Handing over control of your entire supply chain is a massive leap of faith. The relationship must be a true partnership, with open communication, shared goals, and a high degree of cultural alignment.

Loss of Direct Control: The client gives up direct control over day-to-day logistics operations and provider selection. This can be a difficult cultural shift for some organizations that are used to being hands-on.

Higher Cost and Long-Term Commitment: A 4PL partnership is a significant strategic and financial investment. Contracts are typically multi-year, and the implementation process can be complex and time-consuming, involving deep integration of IT systems and business processes.

Potential for Over-Reliance: A business can become highly dependent on its 4PL partner, making it difficult and disruptive to switch providers or bring functions back in-house if the relationship deteriorates.

A 4PL partnership is best suited for:

- Large, Complex Enterprises: Companies with global supply chains, multiple business units, and a high volume of logistical activity that has become too complex to manage internally.

- Businesses Seeking Transformation: Companies that view their supply chain as a source of competitive advantage and are looking for a strategic partner to drive optimization and innovation.

- Organizations Lacking Internal Expertise: Businesses that do not have a large or experienced internal supply chain team and want to outsource this competency entirely.

- Companies Focused on Growth and Expansion: A 4PL can provide the scalable and sophisticated supply chain infrastructure needed to support rapid growth into new products or markets.

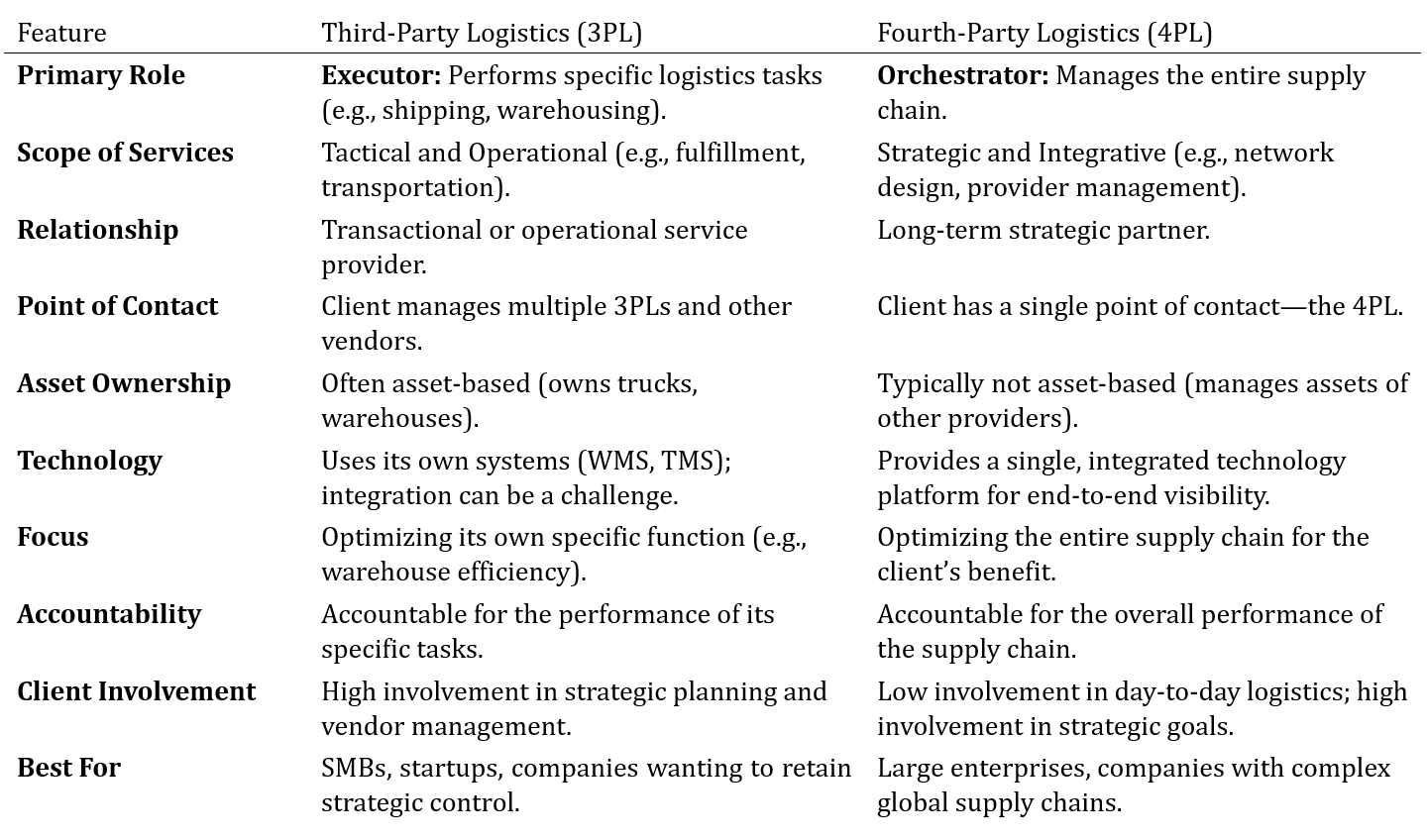

To make an informed decision, it’s helpful to place the two models side-by-side and compare their key attributes directly. The fundamental difference lies in the scope and nature of the relationship: one is a tactical service provider, while the other is a strategic supply chain partner.

Delving deeper into these points reveals the practical differences. In terms of focus, a 3PL is incentivized to fill its own warehouses and trucks. A 4PL, being asset-neutral, is incentivized only to find the most efficient and effective solution for the client, even if it means using multiple, competing 3PLs. Regarding technology, a business using a 3PL might have to log into one portal to track warehouse inventory and another to track freight. A 4PL provides a single dashboard where inventory levels, shipment statuses, and performance analytics are all visible in one place. This difference in visibility directly impacts a company’s ability to be proactive versus reactive. When a disruption occurs, such as a port closure, a business with multiple 3PLs would need to coordinate with each one individually. A 4PL would manage the entire response, rerouting shipments and reallocating inventory across the network seamlessly.

The complexities of sourcing from China add another layer to the 3PL 4PL logistics decision. The journey from a Chinese factory to a warehouse in North America or Europe involves numerous steps: factory pickup, export customs clearance in China, international freight, import customs clearance at the destination, and final-mile delivery. Managing this process effectively is a major challenge.

Supplier Coordination: Managing communication, production schedules, and quality expectations with multiple suppliers across different manufacturing hubs of China is a full-time job, complicated by language barriers and time zone differences.

On-Site Quality Control: Ensuring product quality before the goods are shipped is critical. Once products are on a container ship, it’s too late to fix defects. This requires on-site presence for pre-production, in-line, and final pre-shipment inspections. Effective inspection and quality control is non-negotiable.

Customs and Compliance: Navigating the customs regulations of both China (export) and the destination country (import) requires specialized, up-to-date knowledge. Errors in documentation are a common cause of costly delays and fines.

Fragmented Logistics and Handoffs: The process involves multiple handoffs—from the factory to a local trucker, to a freight forwarder at the port, to a shipping line, to a customs broker, to a drayage carrier, and finally to a destination warehouse. Each handoff is a potential point of failure.

For most businesses importing from China, neither a pure 3PL nor a pure 4PL model perfectly addresses all these challenges. A 4PL might manage the logistics network but won’t handle supplier negotiation or on-site quality control. A 3PL will only handle the specific tasks assigned to it, such as ocean freight or destination warehousing, leaving the client to manage the entire pre-shipment phase in China.

This has given rise to a highly effective hybrid model: combining the expertise of a dedicated sourcing company with a capable logistics partner.

The Role of the Sourcing Partner: A company like Maple Sourcing acts as the client’s on-the-ground team in China. Their role transcends logistics; they are procurement and production management experts. They handle the critical “first mile” of the supply chain, which includes:

- Supplier identification, auditing, and vetting.

- Price and contract negotiation, leveraging local knowledge.

- Managing production schedules and ensuring timelines are met.

- Implementing a rigorous multi-stage quality control plan.

- Consolidating goods from multiple suppliers into a single shipment.

- Ensuring all export documentation is accurate and complete.

The Role of the Logistics Partner (3PL): Once the sourcing partner has approved the goods and prepared them for shipment, they are handed over to a chosen logistics provider. This is typically a freight forwarder or a 3PL that specializes in international transportation. This partner then manages the physical movement of the goods to the destination country.

This hybrid approach offers the best of both worlds. The business gets a dedicated expert managing the immense complexities of procurement and production within China, ensuring quality and reliability at the source. This is a core part of risk management in sourcing. Simultaneously, they can leverage the scale and efficiency of a global 3PL for the transportation and fulfillment aspects. The sourcing agent and the 3PL work in close coordination, but each focuses on their area of core competency. This integrated approach is one of the most effective 3PL solutions for importers.

Selecting between a 3PL, a 4PL, or a hybrid model is a strategic decision with no one-size-fits-all answer. The right choice depends on your company’s unique characteristics, goals, and resources.

Expertise: Do you have an experienced supply chain team in-house? If so, a 3PL model that allows your team to retain strategic control might be best. If not, a 4PL or a sourcing partner who can provide that expertise might be necessary.

Complexity: How complex is your supply chain? If you ship from one location to another, a 3PL is likely sufficient. If you are managing dozens of suppliers, multiple product lines, and several destination markets, the integration and oversight of a 4PL become much more valuable.

Technology: How important is end-to-end visibility? If your team can manage with disparate systems, a multi-3PL approach may work. If a single source of truth is a strategic priority, a 4PL’s integrated technology platform is a significant advantage.

Cost Reduction: If your primary goal is to lower transportation and warehousing costs, a 3PL can provide immediate benefits through its scale and efficiency.

Operational Efficiency: If you are looking to offload time-consuming tasks like order fulfillment to focus on your core business, a 3PL fulfillment company is an excellent choice.

Strategic Transformation: If you believe your supply chain can be a source of competitive advantage and you want a partner to help you re-engineer it for optimal performance, a 4PL is the right direction.

Market Expansion: If you are expanding into a new country, a local 3PL can provide the necessary infrastructure. For a global expansion strategy, a 4PL can design and manage a network that supports your growth.

Startups and SMBs: Typically benefit most from the flexibility and lower entry cost of a 3PL. It allows them to access professional services without a massive upfront investment or long-term commitment.

Mid-Market and Growing Companies: This is often the transition point. As a company’s supply chain becomes more complex, the coordination burden of managing multiple 3PLs can become overwhelming, making a 4PL or a more integrated solution an attractive option.

Large Enterprises: These companies often have the scale and complexity that justify the investment in a 4PL partnership to manage their global logistics networks.

3PL Pricing: Typically transactional, based on volume, space used, or activity (e.g., per order fulfilled, per pallet stored, per shipment moved). This makes costs variable and easy to understand.

4PL Pricing: More complex and often based on a management fee, a percentage of the total logistics spend, or a gain-sharing model where the 4PL is rewarded for achieving specific cost savings or performance improvements. It is a longer-term, more significant financial commitment.

Ultimately, the decision requires a thorough analysis of your needs and a clear understanding of what you want from a logistics partner. Are you looking for a contractor to execute tasks, or a partner to manage your entire supply chain?

The distinction between 3PL 4PL logistics is far more than just a number. It represents a difference in scope, strategy, and the very nature of the partnership. A third party logistics 3PL provider is a tactical ally, an expert executor of specific logistics functions that allows a business to improve efficiency and focus on its core mission. A 4PL, in contrast, is a strategic architect, a master orchestrator that designs, manages, and optimizes the entire supply chain, offering integration and visibility that can transform a company’s competitive standing.

For businesses sourcing from the dynamic and complex market of China, the choice is even more critical. The optimal solution often lies in a hybrid approach—partnering with a specialized sourcing agent to manage the critical first mile of production and quality control, while leveraging a capable 3PL for the global transportation and fulfillment.

The right choice is not determined by which model is “better,” but by which model is best aligned with your company’s size, complexity, and strategic ambition. By carefully evaluating your needs and understanding the distinct value proposition of each model, you can build a logistics framework that is not only efficient and cost-effective but also resilient, scalable, and ready for the challenges of the future. To learn more about how an expert partner can streamline your procurement from Asia, we invite you to explore our comprehensive sourcing services.