What if the single biggest risk in your next product launch wasn’t your marketing budget or your sales strategy, but the very first physical sample you receive from your overseas supplier? For many importers and entrepreneurs, this moment of truth—unboxing a prototype that doesn’t match the digital vision—is where timelines derail, budgets inflate, and confidence in the supply chain crumbles.

In today’s fast-paced market, the gap between a brilliant idea and a market-ready product is often bridged by digital prototyping. This isn’t just about creating a 3D model; it’s a comprehensive process of using specialized prototyping tools to simulate, test, and refine a product’s design, function, and manufacturability entirely in the digital realm before a single piece of material is cut. By investing in a robust prototyping digital workflow, you move from hoping your supplier understands your vision to giving them a precise, unambiguous, and tested blueprint for success.

We believe that a reliable supply chain is built on certainty, not chance. Your role is to innovate and bring products to market; ours is to ensure that journey is smooth, efficient, and predictable. The foundation of that partnership starts with clarity. Digital prototypes serve as that universal language, eliminating the costly game of ‘telephone’ that can happen across continents and cultures.

Consider the common pitfalls that digital prototyping directly addresses:

Misinterpretation of Design: A sketch or verbal description leaves too much room for error. A photorealistic 3D render or an interactive simulation does not.

Overlooked Manufacturing Flaws: A good prototyping tool can run simulations for stress, material flow, and assembly long before tooling is commissioned, catching issues that would be catastrophic on the production line.

Inefficient Revision Cycles: Each physical prototype iteration costs money and weeks of time. Digital iterations cost fractions and can be completed in hours or days, allowing for more creative exploration and perfection.

For the US-based entrepreneur, startup, or procurement manager sourcing from overseas, this shift is a game-changer. It aligns with the core values of risk management, cost control, and transparent communication. When you send a fully realized digital prototyping package to a potential supplier, you’re not just sending files; you’re establishing a standard of professionalism, precision, and collaborative partnership from day one.

This article will guide you through the essential elements of an effective prototyping digital strategy. We’ll explore the key stages, the tools that bring ideas to life, and how this process fundamentally de-risks your procurement journey, builds supplier confidence in your project, and paves the way for a smooth transition from a flawless digital model to a perfect physical product. Let’s build that certainty, together.

As we’ve established the critical importance of a solid prototype, the next logical step is to explore the most efficient and powerful method to create one. Welcome to the world of digital prototyping, your first virtual workshop. This isn’t just about creating a 3D model on a screen; it’s a comprehensive, iterative design and testing process that happens entirely in a digital environment before a single physical part is made.

Think of a digital prototype as a living, breathing simulation of your product. It goes far beyond a static 3D image. A true digital prototype incorporates:

· Geometry & Form: The precise 3D shape and dimensions.

· Material Properties: Simulating weight, flexibility, and strength.

· Kinematics & Motion: How parts move and interact with each other.

· Performance Data: Stress analysis, fluid flow, or thermal behavior.

Using a sophisticated prototyping tool like Autodesk Fusion 360, SolidWorks, or Onshape, you can assemble components, test fits, and even simulate real-world forces. This holistic approach allows you to identify and solve functional and manufacturability issues that a simple sketch or physical mock-up might miss.

The journey from idea to tangible product has been revolutionized. It used to be a linear, costly path: sketch > handmade model > functional prototype > production. Each step required new materials, tools, and significant time. Digital prototyping collapses these stages. Your initial concept sketch can be rapidly turned into a 3D model. That model can then be stress-tested, have its aesthetics refined, and be prepared for manufacturing—all within the same digital file. For complex products, you can even step into a Virtual Reality (VR) environment to experience the scale and ergonomics of your design at full size, making adjustments with unparalleled intuition.

For inventors and entrepreneurs, especially those managing overseas production, prototyping digital methods offer decisive advantages:

· Radical Cost Reduction: Eliminate the expense of multiple physical prototype iterations. A study by the National Institute of Standards and Technology (NIST) highlights that catching design errors digitally can reduce development costs by up to 50%.

· Unprecedented Speed: Iterate designs in hours or days, not weeks. Test ten variations of a hinge mechanism before lunch.

· Enhanced Communication: A 3D digital model is a universal language. It provides crystal-clear instructions to your engineering team and potential suppliers in china, minimizing misinterpretation and ensuring everyone is aligned on the exact design intent.

· Risk Mitigation: By simulating performance and identifying potential failure points early, you de-risk the subsequent physical prototyping and mass production phases. This controlled, virtual testing builds confidence before committing to tooling investments.

Investing time in a prototyping course to master these tools is one of the highest-return activities for a modern product developer. It empowers you to enter discussions with manufacturing partners not just with an idea, but with a validated, optimized, and production-ready digital blueprint. This level of preparation signals professionalism, reduces your supplier’s engineering burden, and sets the stage for a smoother, more predictable path to a successful product launch.

As we’ve seen, digital prototyping is far more than a static 3D model; it’s a dynamic, virtual workshop. This power truly shines when we examine how sourcing works compresses the timeline from a raw idea to a market-ready product. Let’s explore the mechanisms that make this acceleration possible.

The core of this speed is the iterative power loop. In the physical world, each prototype iteration means new tooling, materials, and weeks of waiting. With a prototyping tool in the digital realm, you can test, learn, and refine in a matter of hours or days. Imagine adjusting the ergonomics of a handheld device based on virtual user feedback, running a finite element analysis to check stress points, or simulating airflow in a new fan design—all before a single physical part is made. This loop allows you to explore dozens of design variations, fail fast and cheaply, and converge on the optimal solution with unprecedented speed.

Digital prototypes act as a universal language, seamlessly connecting stakeholders who are often siloed. Your industrial designer in California, your mechanical engineer consulting from Texas, and your target user testing the concept in New York can all interact with the same virtual model. This bridge eliminates costly misunderstandings. Engineering can flag manufacturability issues early, while marketing can gather authentic user reactions to the look and feel. By integrating this feedback directly into the digital prototyping process, you ensure the final product is not only innovative but also practical, desirable, and ready for production.

The acceleration isn’t just theoretical; it translates into tangible, bottom-line benefits. While specific savings vary by project, the qualitative impact is clear across industries:

Development Phase | Traditional Physical Prototyping | With Digital Prototyping | Key Benefit |

Design Exploration | Limited by cost and time; few options tested. | Rapid exploration of numerous concepts and variants. | Drives innovation and finds the best design. |

Engineering Validation | Issues often found late, requiring expensive re-tooling. | Simulations (stress, thermal, fluid) identify problems early. | Prevents costly late-stage changes. |

Stakeholder Alignment | Relies on 2D drawings or expensive physical mock-ups. | Interactive 3D models provide a clear, shared reference. | Reduces errors and accelerates decision-making. |

Path to Production | Multiple physical prototype cycles delay tooling and manufacturing. | A highly refined digital model de-risks the transition to production. | Gets your product to market faster. |

By front-loading the problem-solving into the digital space, you avoid the most expensive mistakes—those discovered during tooling or assembly line trials. Investing time in a comprehensive prototyping course or mastering a prototyping digital workflow is one of the highest-return activities for any modern inventor or product team. It’s the strategic shortcut that turns your vision into a viable, market-leading product with greater efficiency and control.

Now that we’ve explored how digital prototyping accelerates development and saves resources, let’s translate that potential into action. This practical guide walks you through the core stages of creating and refining your digital prototypes, turning your concept into a validated, manufacturable design.

Every successful product starts with a clear purpose. Before opening any prototyping tool, define your invention’s primary function and the specific problem it solves. Who is your user? What are their pain points? Create detailed user scenarios or “storyboards” that describe how someone will interact with your product in real life. For example, if you’re designing a new ergonomic kitchen tool, a scenario might detail a home cook with arthritis preparing a meal. This foundational step ensures your digital prototyping efforts remain focused on user needs, not just technical possibilities.

Not all digital prototypes are created equal. The right fidelity depends on your current goal.

· Low-Fidelity (Lo-Fi): Use simple wireframes or basic 3D shapes to map out layout, user flow, and core mechanics. This is ideal for early brainstorming and internal reviews. Tools like sketching software or even presentation slides can work.

· High-Fidelity (Hi-Fi): This involves creating a detailed, visually rich, and often interactive model that closely resembles the final product. Use advanced 3D modeling software to apply materials, textures, and simulate real-world physics. Hi-fi prototypes are perfect for user testing, investor presentations, and final engineering validation.

Choosing the appropriate level of detail prevents wasted effort and keeps the project moving efficiently.

This is where your concept takes digital shape. Using your chosen software, construct the 3D model of your invention. Modern tools allow you to do more than just create a business model static image; you can run simulations. Test for stress points, fluid dynamics, thermal performance, or assembly sequences. For instance, you can simulate how a plastic housing deforms under pressure or how air flows through a new vent design. This phase transforms your prototype from a visual concept into a functionally analyzed model, identifying potential failures long before physical parts are made.

The true power of a digital prototype is its shareability. You can easily distribute interactive models or realistic renderings to a select group of target users or stakeholders. Gather structured feedback on usability, aesthetics, and perceived value. Do users understand how it works? Does the design feel intuitive? Use this critical input to iterate on your digital model. This loop of build > share > learn > refine is the core of agile development, ensuring the final design is not just technically sound but also market-ready.

By following these steps, you systematically de-risk your invention’s journey. Each iteration on a digital model is an investment in certainty, bringing you closer to a product that is desirable, viable, and manufacturable.

Having gathered user feedback on your digital prototype, the next critical step is selecting the right prototyping tool and method to bring those insights to life. This choice directly impacts your efficiency, cost, and the quality of your final design. Let’s compare the key approaches and platforms to help you make an informed decision.

The first decision is choosing the fidelity of your digital prototyping effort. Research from What is Digital Prototyping? shows. This isn’t about quality, but about purpose.

· Low-Fidelity Prototypes are simple, fast, and focus on core functionality and user flow. Think of wireframes, basic 2D sketches, or simple interactive mockups. They are perfect for early-stage brainstorming, validating core concepts, and gathering broad user feedback without getting bogged down in visual details. Tools like Balsamiq or even paper sketches excel here.

· High-Fidelity Prototypes are interactive, visually rich, and closely mimic the final product’s look, feel, and behavior. They are essential for detailed user testing, stakeholder presentations, and finalizing design specifications before engineering begins. This is where advanced 3D CAD software and interactive UI/UX platforms like Figma or Adobe XD come into play.

Actionable Insight: Start with low-fidelity to validate your idea’s foundation cheaply and quickly. Progress to high-fidelity digital prototypes once the core concept is solid, using them to refine details and de-risk the later manufacturing stages.

The market offers a spectrum of tools, each with strengths for different types of inventions. Here’s a comparative overview to guide your selection:

Tool Category | Best For | Popular Examples | Key Consideration |

3D CAD & Parametric Modeling | Mechanical parts, consumer products, enclosures | Fusion 360, SolidWorks, Onshape | Steeper learning curve, but essential for manufacturable designs and engineering analysis. |

UI/UX & Interactive Mockups | Apps, websites, software interfaces | Figma, Adobe XD, Sketch | Excellent for user journey simulation and visual design iteration. |

Conceptual & Freeform 3D | Organic shapes, artistic designs, initial 3D concepts | Blender, ZBrush | Powerful for visualization but may require conversion for engineering. |

Specialized & Simulation | Electronics (PCBs), fluid dynamics, stress analysis | Altium Designer, ANSYS | Critical for specific technical validation beyond basic form. |

Choosing the right platform depends on your invention’s nature, your team’s skills, and the stage of development. See Prototyping Course for Digital Products and UX Design for further details. Many inventors benefit from a prototyping course on a specific platform to accelerate their proficiency.

Effective prototyping digital strategy involves using the right tool at the right time. Think of it as a toolbox where you select a wrench for one job and a screwdriver for another.

1. Concept & Validation Stage: Use low-fidelity tools (sketching apps, wireframing software) to quickly test assumptions.

2. Design & Engineering Stage: Transition to high-fidelity 3D CAD software (like Fusion 360) to create precise, testable virtual models. This is where you run simulations for stress, motion, or heat.

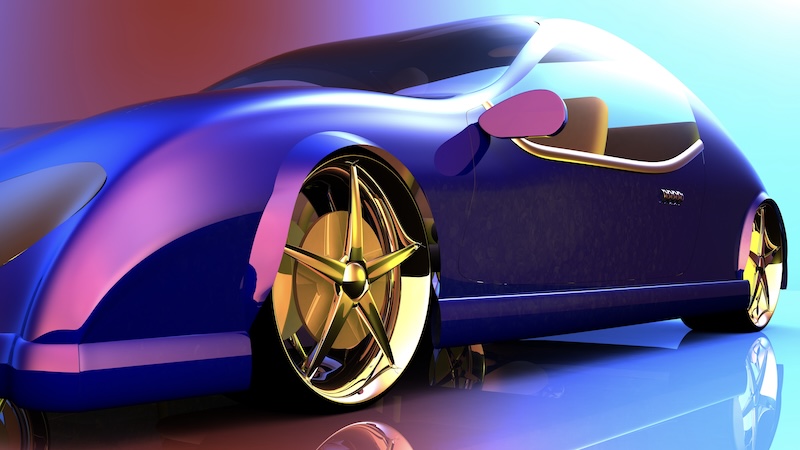

3. Presentation & Refinement Stage: Employ rendering software (Keyshot, V-Ray) or even Virtual Reality (VR) to create immersive, photorealistic presentations for investors, focus groups, or crowdfunding campaigns. VR can be a powerful tool for experiencing scale and ergonomics before any physical part is made.

By strategically matching your prototyping tool to each phase, you maintain momentum, control costs, and build a rock-solid foundation for manufacturing. The goal is to use digital prototyping not as a single step, but as a continuous, adaptable process that de-risks your path from idea to market.

Choosing the right prototyping tool is crucial, but its true power is unlocked when you use it to connect with people. Digital prototyping moves beyond the engineering lab to become your first, most powerful tool for market validation. It allows you to test core assumptions about your invention’s appeal, usability, and market fit long before you commit to costly physical production.

A digital prototype transforms your abstract idea into a tangible experience you can share. It’s a universal communication medium that bridges the gap between your vision and your audience’s understanding. Instead of describing a complex mechanism, you can demonstrate it. This is invaluable for:

· Internal Alignment: Ensuring your entire team—from designers to marketers—shares the same vision.

· Stakeholder Buy-in: Pitching to partners or management with a compelling, interactive demonstration rather than static slides.

· Early Customer Engagement: Gauging initial interest and excitement by showing a “working” model of your future product.

Think of your prototype not just as a technical model, but as the central artifact for all early-stage conversations about your invention’s potential. Digital prototyping: learn and innovate faster provides additional context.

User testing with a digital prototype is a structured way to gather actionable insights. The goal is to observe how real people interact with your concept, identifying points of confusion, delight, or friction.

A simple framework for effective testing:

1. Define Clear Objectives: What do you need to know about a China sourcing agent? Is it about the intuitiveness of a control, the appeal of a form factor, or the clarity of a user workflow?

2. Recruit Representative Users: Find people who match your target demographic. Even a small group of 5-8 users can reveal most major usability issues.

3. Create Realistic Scenarios: Ask users to complete specific tasks using the prototype (e.g., “Show me how you would turn on the device and adjust the settings”).

4. Observe and Listen: Watch where they hesitate or make errors. Ask open-ended questions like, “What are you thinking here?” or “What did you expect to happen?”

5. Iterate Based on Feedback: Use the findings to refine your digital prototype in the next design cycle. This continuous loop of build-test-learn is the core of agile development.

This pre-production validation phase is where digital prototyping delivers immense financial value. Presenting a polished, interactive prototype allows you to solicit strategic feedback from two critical groups:

· Potential Customers & Focus Groups: You can assess purchase intent, perceived value, and feature preferences. This data helps you prioritize development resources and refine your value proposition. You’re not asking, “Do you like my idea?” but rather, “How would you use this product, and what would you pay for it?”

· Investors & Grant Committees: A compelling digital prototype demonstrates far more than a business plan. It shows execution capability, reduces perceived technical risk, and makes the opportunity tangible. Investors can see and interact with your vision, which builds confidence in your team’s ability to deliver.

By integrating user and market feedback into the prototyping digital phase, you de-risk the entire procurement and production journey. More at An Introduction to Digital Prototyping. You move forward with the certainty that you’re building a product people actually want, which is the most reliable foundation for any successful launch.

Gathering user and investor feedback with a digital prototype is a powerful first step. Now, let’s see how this process translates into tangible success for real products. These case studies demonstrate how digital prototyping serves as a critical prototyping tool for managing risk and accelerating time-to-market.

A US-based startup aimed to launch a smart home device. Their initial physical prototype had overheating issues and an awkward form factor, which would have required costly mold retooling. By switching to a high-fidelity prototyping digital approach using thermal and airflow simulation software, the team identified the root cause—poor internal component layout—within the virtual model.

· The Process: They created multiple digital prototypes, iterating on the internal architecture without building a single new physical unit.

· The Result: The final virtual design solved the thermal problem, optimized the ergonomics, and reduced the projected tooling modification costs by over 60%. This virtual validation gave them the confidence to proceed directly to a production-ready prototype, shaving months off their development schedule.

For a novel physical therapy device targeting the US market, regulatory and safety validation is paramount. The inventor needed to prove the device’s mechanical safety and user interaction before engaging with manufacturers and seeking FDA feedback.

· The Process: Using advanced simulation software, the team subjected the digital prototype to stress tests, range-of-motion analyses, and virtual use-case scenarios that mimicked real-world conditions.

· The Result: The simulations revealed a potential pinch point in the mechanism that was not apparent in static CAD models. Addressing this in the digital stage prevented a critical safety failure, de-risked the regulatory pathway, and provided compelling data to secure early-stage investment. This is where a foundational prototyping course in simulation can pay immense dividends.

These cases show that digital prototyping is not just an engineering step; it’s a strategic business tool that builds certainty, controls costs, and transforms a promising idea into a viable, manufacturable product ready for your supply chain. This section presents real-world case studies demonstrating how digital prototyping streamlines product development for consumer electronics and validates critical concepts for regulated devices like medical equipment, highlighting key ROI metrics in cost reduction, speed-to-market, and risk mitigation.

As the real-world case studies demonstrate, digital prototyping is not just a technical step; it’s a strategic business tool that builds certainty. Let’s consolidate the core insights from our exploration of this powerful process, providing you with a clear action plan for your next project.

At its heart, a digital prototyping tool is your first line of defense against costly errors and delays. The primary advantages are clear and consistent:

De-risks Development: By identifying design flaws, material incompatibilities, and manufacturing challenges in a virtual space, you prevent expensive mistakes in physical production.

Accelerates Time-to-Market: Rapid iteration cycles mean you can test ten ideas in the time it takes to build one physical model, compressing your development timeline significantly.

Enhances Communication: A 3D model or simulation is a universal language. It bridges the gap between your vision, your engineering team, potential investors, and end-users, ensuring everyone is aligned.

Controls Costs: The savings are twofold: you avoid the cost of repeated physical builds, and you secure more accurate manufacturing quotes by providing suppliers with a complete digital package.

While selecting the right software is important, success starts with strategy. Your approach should match your project’s stage:

Project Stage | Recommended Fidelity | Primary Goal | Common Tools / Methods |

Concept Validation | Low-Fidelity | Test core functionality & user flow | Basic CAD, wireframes, interactive mockups |

Design Refinement | Medium-Fidelity | Refine ergonomics, aesthetics, and assembly | Advanced CAD (e.g., SolidWorks, Fusion 360), basic simulation |

Engineering & Manufacturing Prep | High-Fidelity | Validate performance and generate production files | High-end CAD/CAE, FEA/CFD analysis, photorealistic rendering |

Remember, the goal isn’t to use the most advanced tool immediately, but to use the right prototyping tool to answer the most critical question at your current stage.

1. Start Early, Start Simple: Don’t wait for a "perfect" idea. Use basic digital sketches or models to give your concept its first tangible form.

2. Define "Done" for Each Stage: Before you begin a prototyping cycle, know what question you need to answer or what decision you need to make.

3. Integrate User Feedback: Use your digital prototypes for early validation with a small, targeted group. Their insights are invaluable for guiding refinement.

4. Iterate with Purpose: Each cycle should have a clear objective—improving strength, reducing part count, enhancing usability—based on data from simulations or tests.

5. Bridge to Procurement: A mature digital prototype, complete with simulations and detailed drawings, is the strongest package you can provide to a manufacturing partner. It demonstrates professionalism, reduces their risk, and leads to more accurate quotes.

For teams new to this process, consider investing in a structured prototyping course to build foundational skills in 3D modeling and design thinking. This knowledge empowers you to better manage the process and collaborate effectively with specialists.

In summary, prototyping digital models transforms invention from a gamble into a managed, evidence-based process. It is the disciplined practice of replacing assumption with analysis, and uncertainty with a clear, visual path forward. By adopting this approach, you don’t just design a product; you architect its successful journey to market.

While selecting the right software is important, success starts with strategy. Your approach should match your project’s stage:

Project Stage | Recommended Fidelity | Primary Goal | Common Tools / Methods |

Concept Validation | Low-Fidelity | Test core functionality & user flow | Basic CAD, wireframes, interactive mockups |

Design Refinement | Medium-Fidelity | Refine ergonomics, aesthetics, and assembly | Advanced CAD (e.g., SolidWorks, Fusion 360), basic simulation |

Engineering & Manufacturing Prep | High-Fidelity | Validate performance and generate production files | High-end CAD/CAE, FEA/CFD analysis, photorealistic rendering |

Remember, the goal isn’t to use the most advanced tool immediately, but to use the right prototyping tool to answer the most critical question at your current stage.

1. Start Early, Start Simple: Don’t wait for a "perfect" idea. Use basic digital sketches or models to give your concept its first tangible form.

2. Define "Done" for Each Stage: Before you begin a prototyping cycle, know what question you need to answer or what decision you need to make.

3. Integrate User Feedback: Use your digital prototypes for early validation with a small, targeted group. Their insights are invaluable for guiding refinement.

4. Iterate with Purpose: Each cycle should have a clear objective—improving strength, reducing part count, enhancing usability—based on data from simulations or tests.

5. Bridge to Procurement: A mature digital prototype, complete with simulations and detailed drawings, is the strongest package you can provide to a manufacturing partner. It demonstrates professionalism, reduces their risk, and leads to more accurate quotes.

For teams new to this process, consider investing in a structured prototyping course to build foundational skills in 3D modeling and design thinking. This knowledge empowers you to better manage the process and collaborate effectively with specialists.

In summary, prototyping digital models transforms invention from a gamble into a managed, evidence-based process. It is the disciplined practice of replacing assumption with analysis, and uncertainty with a clear, visual path forward. By adopting this approach, you don’t just design a product; you architect its successful journey to market.

Having explored the key takeaways, let’s address some of the most common questions we hear from inventors and entrepreneurs about implementing digital prototyping into their workflow.

What is the main difference between a digital prototype and a physical prototype?

A digital prototype is a virtual, computer-generated model of your product. It allows you to test form, fit, function, and user interaction in a simulated environment. A physical prototype is a tangible, manufactured version. The key advantage of starting with a digital prototyping process is that you can test and refine your design countless times at near-zero cost before committing to expensive physical tooling and materials. Think of it as building a perfect blueprint before pouring the foundation.

Do I need to be an engineer or a 3D modeling expert to create a digital prototype?

Not necessarily. The landscape of prototyping tools has evolved dramatically.

· For non-technical founders: Many intuitive platforms allow you to create interactive mockups and wireframes to validate user flows and basic aesthetics without writing a single line of code.

· For technical product development: Creating a high-fidelity, simulation-ready 3D model typically requires skills in CAD (Computer-Aided Design) software. This is where partnering with a professional design engineer or taking a focused prototyping course can provide immense value, ensuring your virtual model is accurate and manufacturable.

How much does digital prototyping typically cost?

Costs can vary widely based on the complexity of your product and the fidelity required.

Fidelity Level | Typical Cost Range (USD) | Primary Tools & Activities |

Low-Fidelity | $0 - $500 | Sketching apps, basic wireframing software, paper prototypes. Focus on concept and user flow. |

Mid-Fidelity | $500 - $5,000 | Advanced UI/UX software (e.g., Figma, Adobe XD), simple 3D modeling. Adds interactivity and more detailed design. |

High-Fidelity | $5,000 - $20,000+ | Professional CAD software (e.g., SolidWorks, Fusion 360), engineering simulation, photorealistic rendering. Includes stress testing, material analysis, and preparing for manufacturing. |

The investment in creating detailed digital prototypes is almost always recouped by avoiding a single costly mistake in physical production.

Can a digital prototype help me secure funding or pre-orders?

Absolutely. A compelling digital prototype is one of the most powerful tools for fundraising and market validation. Instead of a sketch or a verbal description, you can show investors and potential customers a photorealistic rendering, an interactive demo, or simulation data proving your concept works. This tangible proof of progress builds credibility, demonstrates serious commitment, and can be the key to unlocking early capital or generating a waitlist.

What’s the biggest mistake people make when starting with digital prototyping?

The most common pitfall is aiming for perfection in the first iteration. Digital prototyping is an iterative process. Start simple, test your core assumptions, gather feedback, and then refine. Spending months perfecting a virtual model before getting any external input often leads to wasted time. The goal is to fail fast and cheaply in the digital realm to succeed faster and more affordably in the physical world.

How do I choose the right digital prototyping software?

Select your prototyping tool based on your primary goal:

· To validate user experience and app flow: Use UI/UX-focused tools like Figma or InVision.

· To design and engineer a physical product for manufacture: Use industry-standard CAD software like SolidWorks (for complex mechanical parts) or Autodesk Fusion 360 (great for startups and integrated workflows).

· To create a quick 3D visual for presentation: Consider more accessible tools like Tinkercad or SketchUp.

Many platforms offer free trials or community editions, so we recommend experimenting with a couple to see which interface and toolset feel most intuitive for your project.

Having addressed common questions, the core value of digital prototyping is clear: it transforms uncertainty into a manageable, strategic process. This journey from a spark of an idea to a tangible, market-ready product is fraught with risk, especially for overseas buyers navigating complex supply chains. Digital prototyping is not just a technical step; it is the universal language of certainty that bridges continents, disciplines, and expectations.

Think of your digital prototypes as more than just virtual models. They are your most powerful prototyping tool for building trust and de-risking your entire procurement journey. By investing time in this virtual workshop, you achieve several critical outcomes:

· Clarity and Confidence: You move forward with a crystal-clear vision, eliminating costly misunderstandings with manufacturing partners.

· Risk Mitigation: You identify and solve design, engineering, and usability problems before a single physical prototype is built, protecting your budget and timeline.

· Market Validation: You gather invaluable feedback from potential users and investors, ensuring your product meets a real need.

· Efficiency and Speed: You compress the development cycle, accelerating your path from concept to commercial success.

For any entrepreneur, inventor, or procurement manager looking to bring a new product to life, mastering digital prototyping is no longer optional—it’s essential. Whether you’re taking a structured prototyping course or collaborating with experts, the goal is to build a foundation of certainty. This process empowers you to approach manufacturing with confidence, communicate your vision with precision, and ultimately, secure a competitive advantage in the market.

In the world of global sourcing, where distance and complexity can create barriers, digital prototyping is your bridge. It turns abstract ideas into concrete plans, fostering the transparency and reliability that define a successful partnership. By starting with a strong virtual foundation, you ensure that the final physical product not only meets but exceeds expectations, delivering value to your customers and growth to your business.