In the sprawling, interconnected universe of global commerce, strategic decisions made in the boardroom have a direct and profound impact on the bottom line. Among the most critical of these is the choice of a sourcing strategy. It’s a decision that dictates not just the cost of goods, but the quality of products, the resilience of the supply chain, and the very nature of a company’s relationship with its manufacturing base. For any business looking to import goods, particularly from a manufacturing titan like China, understanding the fundamental difference between direct and indirect sourcing is not just academic—it’s the cornerstone of a successful international trade venture. The debate over direct sourcing vs indirect sourcing represents two divergent philosophies, each with a unique architecture of risks, rewards, and operational demands.

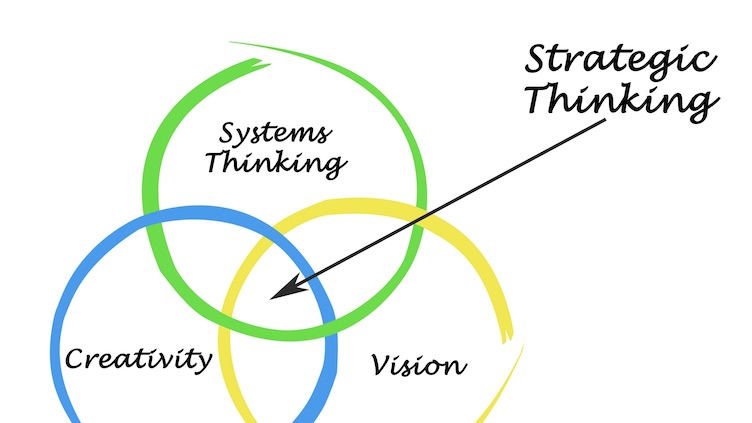

At its core, the choice boils down to a single question: How involved do you want to be in your own supply chain? Do you prefer to take the reins completely, communicating directly with factories and managing every nuance of the production process? This is the world of direct sourcing. Or do you prefer to leverage the expertise and networks of a third party, delegating the complexities of on-the-ground operations to a trusted partner? This is the path of indirect sourcing. This guide will provide a comprehensive deep-dive into the worlds of direct purchase and indirect purchase, meticulously dissecting their mechanisms, advantages, and inherent challenges. Our goal is to equip you with the knowledge to not just choose a path, but to craft a sourcing strategy that is perfectly aligned with your business goals, resources, and vision for growth.

Direct sourcing is the quintessential hands-on approach to procurement. It is the practice of engaging and contracting directly with the manufacturer of your goods, eliminating any intermediaries from the core transaction. When a business opts for a direct purchase vs indirect purchase model, it is choosing to build its own supply chain from the ground up. This means the company’s own team is responsible for every critical step of the journey, from identifying and vetting the factory to negotiating prices, monitoring production, ensuring quality control, and managing the intricate dance of international logistics. It’s a path that offers the ultimate level of control, but also demands a significant investment in resources and expertise.

The Mechanics of the Direct Approach

Embarking on the direct sourcing journey requires a systematic and diligent process. It’s far more than simply finding a supplier on a B2B platform and placing an order.

Factory Identification and Due Diligence: The first step is to find potential manufacturing partners. This can be done through online platforms like Alibaba, attending international trade fairs such as the Canton Fair, or through industry referrals. However, finding a factory is just the start. The critical phase is due diligence. This involves verifying the factory’s legitimacy, checking their business licenses, assessing their certifications (like ISO 9001), and confirming they are a genuine manufacturer, not a trading company masquerading as one.

Direct Communication and Negotiation: Once a shortlist of potential factories is created, the process of direct communication begins. This involves detailed discussions about product specifications, materials, production capacity, and, of course, pricing. Negotiation is a key skill here, as is the ability to navigate potential cultural and language barriers to arrive at a mutually beneficial agreement covering aspects like Minimum Order Quantity (MOQ), payment terms (e.g., 30% upfront, 70% upon completion), and production lead times.

Managing Production and Quality Control: In a direct sourcing model, you are your own quality guarantor. This means establishing clear quality standards and inspection criteria within your contract. It often requires your own staff, or a hired inspector, to be physically present at the factory for key production milestones: a pre-production check to verify materials, an in-line inspection to catch issues mid-process, and a final random inspection before the goods are packaged and shipped.

Handling Logistics and Compliance: With the goods produced and approved, the final step is getting them from the factory floor in China to your warehouse. This involves managing international freight (sea or air), handling customs clearance in both countries, ensuring all documentation is accurate, and navigating a complex web of international trade regulations.

The Strategic Advantages of Going Direct

Companies that successfully master direct sourcing can unlock a host of powerful competitive advantages.

Significant Cost Advantages: The most cited benefit of direct sourcing is the potential for cost savings. By eliminating the commission or markup that would be paid to a sourcing agent or trading company, businesses can achieve a lower per-unit cost, which can either be passed on to the consumer for a more competitive market price or retained to improve profit margins.

Unparalleled Control Over Production and Quality: Direct engagement means you have the final say on every aspect of your product. You can dictate the exact materials used, monitor the production process closely, and implement your own rigorous quality control standards. This level of control is paramount for brands where quality and specific design features are a key part of their value proposition.

Building Strong, Collaborative Supplier Relationships: Working directly with a factory allows you to build a long-term, strategic partnership. Over time, this relationship can evolve from purely transactional to highly collaborative, leading to benefits like prioritized production schedules, better payment terms, and even joint investment in product development and innovation.

Enhanced Intellectual Property (IP) Protection: When you work directly with a factory, you can implement robust, direct legal agreements, such as NDA contracts, that are specifically designed to protect your designs and patents. This direct legal link is often stronger than one filtered through an intermediary.

Full Supply Chain Transparency: The direct model provides a clear line of sight into your supply chain. You know exactly where your products are being made, who is making them, and what components are going into them. This transparency is increasingly important for companies focused on ethical sourcing, social compliance, and environmental standards.

Navigating the Challenges and Risks

While the benefits are compelling, the path of direct sourcing is fraught with challenges that can easily overwhelm the unprepared.

Intensive Resource Commitment: Direct sourcing is not a passive activity. It requires a significant commitment of time, capital, and skilled personnel. Your team needs to have expertise in international sourcing, negotiation, quality control, and logistics.

Navigating High Minimum Order Quantities (MOQs): Factories often impose high MOQs to make a production run profitable for them. For small businesses or those testing a new product, meeting these high volume requirements can be a major financial and logistical hurdle.

Direct Exposure to Risks: Going direct means you assume all the risk. There’s no buffer. If you select the wrong factory, you could fall victim to a scam. If you don’t manage quality control diligently, you could receive a shipment of defective products. Cultural and language barriers can lead to costly misunderstandings regarding product specifications.

Complex Logistics and International Compliance: The world of international shipping and customs is notoriously complex and ever-changing. Managing this process requires specialized knowledge to avoid delays, unexpected fees, and compliance penalties.

If direct sourcing is the hands-on approach, indirect sourcing is the strategic delegation of procurement. It involves engaging a third-party intermediary—such as a sourcing agent, a trading company, or a wholesaler—to manage the process of finding, vetting, and coordinating with manufacturers on your behalf. This is a clear example of the difference between direct and indirect sourcing; instead of building your own supply chain, you are tapping into an existing one. It’s a path chosen by a vast number of importers, from startups to large corporations, who seek to mitigate risk, reduce operational workload, and leverage specialized on-the-ground knowledge, particularly in complex markets like China.

The Indirect Sourcing Ecosystem

Understanding direct sourcing and indirect sourcing requires familiarity with the key players in the intermediary landscape. Each offers a different level of service and engagement.

Sourcing Companies: These are firms or individuals who act as your representative on the ground. Their primary role is to work in your best interest to find and qualify factories, negotiate terms, manage production, and oversee quality control. A good sourcing agent provides a comprehensive service, essentially acting as your remote procurement office. This model offers a high degree of service and alignment with the buyer’s goals.

Trading Companies: Trading companies purchase goods from various factories and then sell them to overseas buyers. Unlike sourcing agents, their primary customer is you, the buyer, but their relationship with the factory is that of a client. They often have established product catalogs and can be a good option for buyers looking for standard products from multiple categories. However, transparency can be a challenge, as they may not always disclose the actual factory of origin.

Wholesalers on B2B Platforms: This represents the most hands-off form of indirect sourcing. Platforms like Alibaba connect buyers with millions of sellers, many of whom are trading companies or wholesalers. While these platforms offer immense choice, the onus of vetting the supplier and managing the entire process falls almost entirely on the buyer, blending the lines between direct and indirect sourcing and carrying significant risk if not managed carefully.

The Strategic Advantages of the Indirect Path

Opting for an indirect sourcing strategy offers a compelling set of benefits, especially for businesses that are new to importing or lack extensive internal resources.

Immediate Access to a Vetted Supplier Base: Established sourcing companies and trading companies have spent years building and vetting their networks of factories. By partnering with them, you can bypass the long and risky process of finding and qualifying reliable suppliers on your own.

Reduced Workload and Operational Burden: Indirect sourcing allows you to outsource the most time-consuming and complex aspects of procurement. Your team is freed from the daily grind of factory communication, production monitoring, and troubleshooting, allowing them to focus on core business activities like marketing, sales, and product development.

Expert Negotiation and Communication: Experienced intermediaries are skilled negotiators who understand the local market and cultural nuances. They can often secure better pricing and terms than a foreign buyer might on their own. Crucially, they bridge the language barrier, ensuring your product specifications and quality standards are communicated with perfect clarity.

Flexibility with Lower Order Volumes: Intermediaries often have relationships with multiple factories and can place orders for various clients simultaneously. This leverage allows them to negotiate lower MOQs, making it possible for smaller businesses to access top-tier factories that would otherwise be out of reach.

Streamlined Quality Control and Logistics Management: Professional sourcing partners provide robust quality control services, with inspectors on the ground to monitor production and ensure standards are met before final payment. They are also experts in logistics, able to consolidate shipments, optimize shipping routes, and manage all the necessary documentation for a smooth customs clearance process.

The Caveats and Considerations

Despite its advantages, the indirect approach is not without its own set of potential drawbacks that must be carefully considered.

Higher Per-Unit Costs: Intermediaries provide a valuable service, and they are compensated for it, typically through a commission or a markup on the product cost. This means the per-unit cost in an indirect model will almost always be higher than the price you could get by going directly to the factory.

Reduced Transparency and Control: When you work through a third party, you often lose a degree of transparency. You may not know the exact identity of the factory producing your goods, making it harder to build a direct relationship or ensure specific ethical standards are being met. Your control over the production process is also filtered through the intermediary.

Risk of Dependence on the Intermediary: Relying heavily on one sourcing partner can create dependency. If that partner’s performance falters or their business priorities change, it can cause significant disruption to your supply chain.

Potential for Communication Lapses: While a good intermediary is a great communicator, a poor one can be a bottleneck. If your instructions are not relayed accurately and promptly to the factory, it can lead to production errors and delays. The quality of your sourcing partner is paramount.

The decision between a direct and indirect sourcing strategy is one of the most consequential a business can make. There is no universal “best” choice; the optimal path is deeply contextual, hinging on a company’s unique DNA—its size, resources, product complexity, and appetite for risk. The direct purchase vs indirect purchase decision is not merely operational, but deeply strategic. Choosing the right framework requires an honest assessment of your organization’s capabilities and goals.

Making the Right Choice for Your Business

To navigate this decision, consider the following key factors:

Company Size and Resources: Large enterprises with dedicated procurement teams, in-house engineers, and significant capital are often well-equipped to handle the demands of direct sourcing. Conversely, startups and small to medium-sized enterprises (SMEs) may find that the expertise and reduced workload offered by indirect sourcing provide a more efficient and less risky path to market.

Order Volume and Scale: Direct sourcing is a volume game. If you can meet the high MOQs demanded by factories, you can unlock significant cost advantages. If your orders are smaller, more frequent, or for a wide variety of products, the ability of an indirect sourcing partner to consolidate orders and negotiate lower MOQs is a powerful advantage.

Product Complexity and IP Sensitivity: If your product is highly technical, requires precise engineering, or involves sensitive intellectual property, the control and direct legal oversight of a direct sourcing model can be critical. However, if the product is simpler, or if you are working with an exceptionally trustworthy and specialized sourcing agent, the indirect model can still be highly effective.

Team Experience and Market Knowledge: Does your team have experience in international trade, quality control, and logistics? Do you understand the cultural and business nuances of the country you are sourcing from? If not, the learning curve for direct sourcing can be steep and costly. Indirect sourcing allows you to essentially “rent” this experience.

Risk Tolerance: How much risk are you willing to assume? Direct sourcing places all the risk—of scams, quality issues, shipping delays—squarely on your shoulders. Indirect sourcing, while not risk-free, provides a buffer, as a good partner will have processes in place to mitigate these risks.

Sourcing Strategies by Product Category

To make this framework more tangible, let’s analyze the direct sourcing vs indirect sourcing decision across several popular product categories sourced from China:

Sourcing Custom Electronics: This category is defined by high complexity, rapid technological change, and significant IP risk. For an established company like Apple, direct sourcing is the only viable option; they need absolute control over every component and a deep, integrated relationship with assemblers like Foxconn. For a startup launching a new gadget, however, going direct could be disastrous. The risk of design theft and the complexity of managing a multi-component supply chain are immense. Here, a specialized indirect sourcing agent who can vet secure factories and manage the intricate assembly process is invaluable.

Sourcing Fashion & Apparel: The fashion industry is driven by fast-moving trends and the need for flexibility. A large brand like Zara or H&M will use a hybrid approach. They’ll go direct for their core, high-volume items to maximize cost savings. For smaller, trend-driven collections, they may use a network of trusted trading companies and agents (direct sourcing and indirect sourcing in tandem) who can offer speed and access to a diverse range of fabric mills and garment factories. A small boutique brand, on the other hand, would almost certainly benefit from an indirect approach to avoid being burdened by high MOQs for each style and color.

Sourcing Standardized Consumer Goods (e.g., Kitchenware, Pet Supplies): For these items, quality is important, but the designs are often not highly proprietary. The decision here often comes down to a classic cost-benefit analysis. A large retailer like Walmart will go direct to the factory to source millions of units, negotiating fiercely to get the lowest possible price. A smaller online seller, however, can thrive using an indirect model. A sourcing agent can find a reliable factory, ensure consistent quality, and even consolidate shipments of different products (e.g., spatulas, bowls, and whisks) into a single container, a logistical feat that would be difficult to manage directly.

Sourcing Promotional Items: This category is characterized by high customization, relatively low order volumes, and tight deadlines for events or marketing campaigns. It is almost always best suited for indirect sourcing. A sourcing agent can quickly find a factory that specializes in custom printing on a wide array of products (pens, T-shirts, USB drives), manage the proofing process, and ensure the goods are delivered on time for the trade show or product launch. The hassle and risk of trying to manage this directly for a one-off, small-batch order would far outweigh any potential cost savings.

In the contemporary global trade environment, the traditional view of a “middleman” is becoming obsolete. The conversation is evolving beyond a simple binary choice between direct and indirect sourcing. A new model has emerged, that of the modern sourcing partner, a firm that operates not as a mere intermediary, but as a strategic, integrated extension of its client’s own team. These companies, like Maple Sourcing, effectively bridge the gap, offering the control and transparency benefits of a direct approach while providing the expertise, risk mitigation, and on-the-ground presence of an indirect one.

This evolution is critical for businesses looking to professionalize their procurement from China. A strategic partner does more than just find factories; they build and manage resilient supply chains. They bring a level of sophistication and professionalism that can transform a company’s entire sourcing operation. When you engage such a partner, you are not just outsourcing tasks; you are insourcing expertise. This allows you to leverage deep local knowledge and established networks without the immense overhead and risk of setting up your own overseas office. For many businesses, this hybrid approach represents the best of both worlds.

The Value-Added Services of a Strategic Partner

The true value of a modern sourcing partner lies in the comprehensive suite of services they provide, each designed to address a critical pain point in the international procurement process.

In-Depth Factory Auditing and Vetting: A strategic partner goes far beyond a basic background check. They conduct rigorous, on-site factory audits that assess not just production capacity, but also quality management systems, social compliance standards, financial stability, and technical expertise. This in-depth vetting process ensures you are partnered with a reliable, ethical, and capable manufacturer, a cornerstone of effective procurement. To truly understand this meticulous process, you can explore our detailed guide on sourcing products from China.

Professional Negotiation and Contract Management: Armed with local market knowledge and extensive experience, a sourcing partner can negotiate more effectively on your behalf. They secure not only competitive pricing but also favorable terms for MOQs, payment, and lead times. Furthermore, they help draft robust, bilingual purchase contracts that clearly define product specifications, quality standards, and penalties, providing you with crucial legal protection.

On-the-Ground Quality Control: This is perhaps the most critical service. A modern sourcing partner deploys their own team of professional inspectors to the factory floor. They monitor your production run at key stages, from raw material inspection to in-process checks and a final, pre-shipment inspection. This ensures that quality issues are caught and corrected before your goods ever leave China, saving you from the disastrous financial and reputational cost of receiving a defective shipment.

Managing Complex Logistics and Shipment Consolidation: Navigating international logistics is a full-time job. A sourcing partner manages this entire process, from coordinating factory pickup to booking freight, handling customs documentation, and tracking the shipment to your door. For businesses sourcing multiple products, they can offer shipment consolidation, combining goods from different factories into a single container, dramatically reducing shipping costs. These vital functions are part of the comprehensive sourcing services that form the backbone of a secure supply chain.

By handling these complex and critical functions, a strategic partner allows your business to focus on its core competencies: innovation, marketing, and customer service. As you look to build a world-class supply chain, consider the immense value of having a dedicated, expert team on the ground. A partnership with a trusted company like Maple Sourcing can be the key to unlocking your business’s full potential in the global marketplace.

The journey through the landscapes of direct and indirect sourcing reveals a fundamental truth: there is no single, monolithic solution to procurement. The choice between taking full, unmitigated control and leveraging specialized, on-the-ground expertise is not a simple tactical decision—it is a profound strategic one. The difference between direct and indirect sourcing is ultimately a difference in philosophy, resource allocation, and risk management. It’s about honestly assessing your company’s strengths, weaknesses, and ambitions, and then crafting a sourcing architecture that serves those specific needs.

For some, the allure of cost savings and total control offered by the direct path will be irresistible, and they will wisely invest the significant resources required to navigate its challenges. For others, the efficiency, risk mitigation, and market access provided by the indirect path will be the more prudent and effective strategy. And for a growing number, a hybrid approach, facilitated by a modern sourcing partner, will offer the perfect synthesis of control and expertise.

What is certain is that in the dynamic and often turbulent waters of international trade, your sourcing strategy is your rudder. A well-crafted strategy, thoughtfully aligned with your business’s unique context, will steer you towards profitability, quality, and a resilient, competitive supply chain. A poorly considered one can leave you adrift in a sea of unforeseen costs, quality disasters, and logistical nightmares. As you move forward, view this decision not as a one-time choice, but as an ongoing strategic process, constantly refined and adapted to meet the ever-changing demands of the global market. Your long-term success depends on it.

Popular Topics You May Be Interested in: