In the complex global marketplace, the way a company acquires its goods and materials is as crucial as the products it sells. The procurement strategy underpins the entire supply chain, influencing cost structures, product quality, operational efficiency, and ultimately, a company’s competitive standing. At the heart of this strategy lies a fundamental choice: engaging in direct vs indirect sourcing. This decision is not merely an operational tactic; it is a strategic imperative that shapes the very nature of a business’s relationship with its supply base. Understanding the nuances of direct procurement vs indirect procurement is essential for any business, especially those looking to tap into the vast manufacturing landscape of China.

Direct sourcing refers to the practice of procuring materials and components that are directly incorporated into the final product. It is the acquisition of “cost of goods sold” items. Indirect sourcing, on the other hand, involves purchasing goods and services that are necessary for the day-to-day operations of the business but are not part of the final product itself. This is often referred to as “not for resale” procurement. The direct and indirect sourcing difference is stark, with each approach offering a unique set of advantages, challenges, and strategic implications.

Choosing the right path requires a deep analysis of your business model, industry, risk tolerance, and long-term objectives. Is it better to build close, collaborative relationships directly with manufacturers to control every aspect of your product? Or is it more efficient to leverage the expertise and infrastructure of intermediaries to manage the complexities of procurement? This guide will provide a comprehensive exploration of indirect sourcing vs direct sourcing, delving into the core concepts, benefits, and drawbacks of each. We will explore real-world scenarios, provide a framework for making the right choice for your business, and offer specific insights for companies navigating the dynamic world of sourcing from China. By the end, you will have a clear understanding of what is direct vs indirect procurement and be equipped to build a sourcing strategy that fuels your success.

Direct sourcing is the quintessential model of procurement where a company bypasses intermediaries and establishes a direct line of communication and business with the manufacturers or producers of its goods. This is the path taken by companies that wish to have their hands firmly on the steering wheel of their production and supply chain.

At its core, direct sourcing involves the procurement of all the raw materials, components, and parts that are essential for creating a company’s end product. For an apparel brand, this would mean sourcing fabrics, zippers, and buttons directly from textile mills and accessory factories. For a consumer electronics company, it would involve procuring microchips, casings, and screens from specialized component manufacturers.

This model is characterized by several key features:

Direct Relationships: The purchasing company builds and maintains a direct, one-to-one relationship with the factory.

High Level of Control: Companies have maximum control over product specifications, quality standards, production schedules, and raw material selection.

Deep Involvement: It requires significant involvement from the company’s procurement, engineering, and quality assurance teams.

Strategic Partnerships: The most successful direct sourcing models evolve into strategic partnerships, where the buyer and supplier collaborate on design, innovation, and cost-saving initiatives.

For businesses looking to create unique products, the direct approach is often paramount. It’s the foundation of creating a private label brand, so how to find private label manufacturers?

The allure of direct sourcing lies in the significant benefits it can offer to companies with the resources and expertise to manage it effectively.

Enhanced Cost Control and Transparency: By eliminating intermediaries, companies can avoid paying markups and commissions, often leading to a lower per-unit cost. The direct procurement vs indirect procurement cost analysis frequently favors the direct model for large volumes. It also provides complete cost transparency; you know exactly what you are paying for materials, labor, and overhead. This granular understanding allows for more effective cost-saving negotiations and initiatives.

Unparalleled Quality Control: When you work directly with a factory, you have the authority to define and enforce your own quality standards. Your team can conduct on-site inspections at various stages of production, from raw material verification to final product testing. This hands-on approach is critical for complex products or brands where quality is a key differentiator. A deep dive into inspection and quality control in manufacturing is essential for any direct sourcing strategy.

Greater Control Over the Supply Chain: Direct sourcing provides superior visibility and control over the entire production process. You can monitor production progress, manage lead times more effectively, and respond more quickly to potential disruptions. This control is vital for just-in-time manufacturing models and for businesses that need to be agile in response to market changes.

Opportunities for Collaboration and Innovation: A direct relationship fosters a collaborative environment. You can work closely with the manufacturer’s engineering team to optimize product design for manufacturability, explore new materials, and co-develop innovative features. This partnership can lead to a significant competitive advantage in the marketplace.

Stronger IP Protection: While IP risk is always a concern when outsourcing, a direct, legally-binding contract with a single factory can provide a clearer framework for protecting your intellectual property compared to working through intermediaries where your designs may be exposed to more parties. Understanding how to protect your product idea is a critical first step.

Despite its advantages, direct sourcing is a demanding and resource-intensive strategy. It is not without its significant challenges, particularly for small to medium-sized enterprises (SMEs).

High Resource Requirement: It requires a dedicated and experienced procurement team with the skills to identify, vet, negotiate with, and manage overseas suppliers. This includes engineers for technical specifications, quality inspectors, and logistics experts.

Significant Time and Effort: Finding the right factory is a laborious process. It involves extensive research, communication, sample evaluation, and factory audits. Managing the relationship, overseeing production, and resolving issues requires a continuous investment of time.

Higher Risk and Liability: With direct sourcing, you bear the full responsibility for the relationship. If a shipment is delayed, if quality issues arise, or if the supplier fails to comply with regulations, the onus is on you to resolve it. There is no intermediary to act as a buffer or share the liability. Exploring risk management in sourcing becomes a core competency.

Cultural and Language Barriers: When sourcing from a country like China, navigating cultural differences and language barriers can be a major hurdle. Miscommunication can lead to costly errors in production and strained relationships.

Higher Minimum Order Quantities (MOQs): Factories often impose high MOQs, which can be a significant barrier for smaller businesses or for those testing a new product. This can tie up a large amount of capital in inventory. How to negotiate lower MOQ? is a key skill in direct sourcing

Complex Logistics Management: You are responsible for managing the entire logistics process, from factory pickup to international shipping, customs clearance, and final delivery. This requires significant expertise and coordination.

Direct sourcing is a powerful strategy for established companies with the scale, expertise, and resources to build and manage a global supply chain. For these businesses, the benefits of control and cost savings often outweigh the inherent complexities.

If direct sourcing is about taking the wheel, indirect sourcing is about hiring a professional chauffeur. It involves engaging one or more intermediaries, such as sourcing agents, trading companies, or wholesalers, to manage the procurement process on your behalf. This model is focused on leveraging external expertise to navigate the complexities of the global market.

Indirect sourcing is the procurement of goods through a third party. Instead of contracting directly with a factory, you contract with an agent or trading company that, in turn, manages the relationship with the manufacturer. This model is particularly common for businesses that are new to importing, have limited resources, or source a wide variety of products from multiple factories.

Key characteristics of indirect sourcing include:

Use of Intermediaries: The primary relationship is with a sourcing partner, not the end factory.

Reduced Direct Involvement: The intermediary handles many of the time-consuming tasks of procurement, such as supplier identification, negotiation, and logistics.

Access to Networks: Sourcing agents provide access to their established network of vetted factories.

Service-Based Model: You are paying for a service that simplifies the procurement process.

This approach is often seen as a gateway to international trade, providing a lower-risk entry point. A key question for many is what is a sourcing agent and how they can facilitate this process.

The primary benefits of indirect sourcing revolve around efficiency, convenience, and risk reduction, making it an attractive option for many businesses.

Reduced Workload and Time Savings: This is perhaps the most significant advantage. The sourcing partner handles the labor-intensive tasks of finding and vetting suppliers, negotiating prices, managing production, and arranging logistics. This frees up the business to focus on its core competencies, such as sales, marketing, and product development.

Lower Barrier to Entry: Indirect sourcing is far more accessible for SMEs. It does not require a large, dedicated procurement team. The lower MOQs often offered by trading companies also make it easier for smaller businesses to get started. Click to learn How to negotiate lower MOQ?

Access to Expertise and Networks: Professional sourcing agents possess deep knowledge of their local market. They understand the manufacturing landscape, have established relationships with reliable factories, and can navigate cultural and language barriers effectively. This local expertise is invaluable, especially in a market as complex as China.

Consolidation and Flexibility: An intermediary can consolidate orders for multiple products from different factories into a single shipment, simplifying logistics and potentially reducing shipping costs. They can provide greater flexibility, allowing you to source a wide variety of items without having to manage dozens of individual factory relationships.

Risk Mitigation: A good sourcing agent acts as a risk buffer. They are responsible for ensuring the factory meets quality standards and production deadlines. If a problem arises, they are your first line of defense and are responsible for finding a solution. They can help you avoid common scams and pitfalls associated with sourcing from unknown overseas suppliers.

Simplified Communication: You have a single point of contact, which streamlines communication. The agent is responsible for translating your requirements to the factory and ensuring they are clearly understood, minimizing the risk of miscommunication.

While convenient, the indirect model is not without its trade-offs. The indirect sourcing vs direct sourcing debate often highlights these potential disadvantages.

Higher Per-Unit Cost: Intermediaries are businesses that need to make a profit. Their fees or markups are added to the cost of the goods, resulting in a higher per-unit price compared to what you might achieve through direct negotiation.

Lack of Transparency: It can be difficult to get a clear picture of the true factory price. The intermediary may not disclose their margin, leaving you unsure of the actual cost breakdown. This lack of transparency can hinder your ability to conduct effective cost analysis.

Less Control Over the Supply Chain: You are one step removed from the production process. This can lead to less control over quality, production schedules, and material selection. You are reliant on the agent’s ability to enforce your standards.

Potential for Communication Gaps: While the agent simplifies communication, they also represent an extra layer in the communication chain. There is always a risk that nuances or critical details of your requirements could be “lost in translation” between you, the agent, and the factory.

Limited Relationship with the Manufacturer: You do not build a direct relationship with the factory. This can limit opportunities for deep collaboration, joint innovation, and building long-term strategic partnerships. The factory’s primary loyalty is to the agent, not to you.

Indirect sourcing is an excellent choice for businesses that prioritize convenience, risk reduction, and speed to market over having absolute control and achieving the lowest possible unit cost. It is a strategic enabler for companies that want to leverage global manufacturing without building a massive in-house procurement infrastructure.

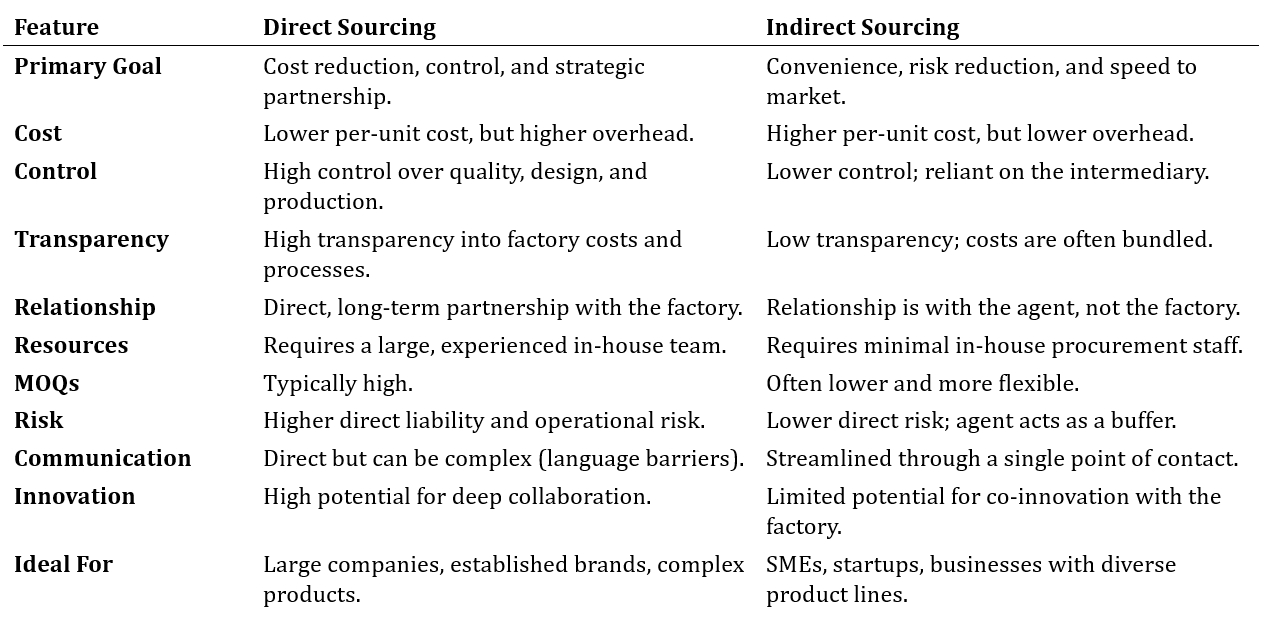

To truly grasp the direct and indirect sourcing difference, it’s helpful to place the two models side-by-side and compare them across several critical business dimensions. This comparison will help illuminate what is direct vs indirect procurement and guide you toward the strategy that best aligns with your company’s profile and objectives.

Let’s delve deeper into the most critical points of comparison.

The direct procurement vs indirect procurement cost argument is nuanced. Direct sourcing offers a lower landed cost per unit because it cuts out the intermediary’s margin. However, it demands a higher overhead cost in the form of salaries for a procurement team, travel expenses for factory visits, and investment in management systems.

Indirect sourcing has a higher landed cost per unit but a much lower overhead cost. For a small business, the savings in overhead can far outweigh the agent’s commission. A large corporation with high-volume orders, however, will find that the savings from eliminating the commission quickly justify the investment in an in-house team.

Direct sourcing provides the ultimate control over quality. You set the standards, you conduct the inspections, you approve the final product. This is essential for brands built on a reputation for superior quality.

In indirect sourcing, quality management is outsourced to the agent. The quality of your product is therefore only as good as the quality of your agent’s inspection process. This requires a high degree of trust in your sourcing partner. Choosing a partner with a robust framework for third-party quality control services is non-negotiable.

The risk profiles of the two models are inverted. With direct sourcing, you assume all the operational and financial risks. You are directly liable for contracts, payments, and any disputes that arise.

Indirect sourcing transfers a significant portion of this operational risk to the agent. They are contractually obligated to deliver the goods as specified. This can be particularly valuable when navigating unfamiliar legal and commercial environments. However, it introduces a new risk: agent risk. If your agent is unreliable or unethical, your entire supply chain is compromised. Therefore, the most critical step in indirect sourcing is the rigorous vetting of the agent themselves.

For businesses with a simple, high-volume product line, direct sourcing is highly scalable. As your volume increases, your per-unit cost decreases, and the benefits of control become more pronounced.

For businesses with a wide and frequently changing product mix, indirect sourcing is often more scalable. An agent can efficiently source a variety of different products from their network of factories, a task that would be incredibly time-consuming for an in-house team to manage from scratch for each new product. They can help you buy in bulk from China across a diverse range of items.

China remains the world’s factory, a dominant force in global manufacturing offering unparalleled production capacity, a highly developed supply chain, and competitive pricing. However, it is also a market with unique complexities. Applying the direct vs indirect sourcing models here requires a special understanding of the landscape.

Whether you choose the direct or indirect path, several factors are critical for success in China:

Guanxi: The concept of relationships and networks is deeply embedded in Chinese business culture. Building strong “guanxi” is crucial. In a direct model, this means investing years in building trust with a factory. In an indirect model, you are leveraging the agent’s existing “guanxi.”

Manufacturing Clusters: China’s manufacturing is highly specialized by region. For example, Shenzhen is the hub for consumer electronics, Foshan for furniture, and the Yangtze River Delta for textiles. Knowing manufacturing hubs in China is essential. A sourcing agent will have this knowledge inherently.

Supplier Verification: The risk of scams and encountering unqualified suppliers is real. Rigorous verification is a must. This includes verifying business licenses, certifications, and, most importantly, conducting on-site factory audits. Understanding the importance of China factory audits can save you from costly mistakes.

A large, established electronics brand wants to manufacture its new line of smart home devices. They have a team of engineers and a mature global supply chain department.

Why Direct is Suitable: They need absolute control over the highly complex technical specifications and software integration. Quality is paramount to their brand reputation. Their high-volume production means that even a small percentage saved per unit by cutting out an agent translates into millions of dollars.

Their Process:

1. Their team spends months researching and shortlisting top-tier electronics manufacturers in Shenzhen and Dongguan.

2. They conduct extensive, multi-day audits of the top 3 factories, evaluating not just production lines but also R&D capabilities and social compliance.

3. They negotiate a detailed, multi-year contract directly with the chosen factory, including strict IP protection clauses.

4. They embed their own quality engineers at the factory during the New Product Introduction (NPI) phase to oversee production ramp-up.

5. They manage the complex logistics of shipping millions of units globally, leveraging their existing contracts with major freight carriers.

A new e-commerce startup wants to sell a curated collection of 20 different home decor items, from ceramic vases to wall art and small furniture.

Why Indirect is Suitable: They have a small team of 5 people and limited capital. Their expertise is in digital marketing and brand building, not international procurement. Managing 20 different factory relationships would be impossible.

Their Process:

1. They research and vet several China-based sourcing companies, choosing one with a strong track record in the home decor category.

2. They provide their sourcing partner, like Maple Sourcing, with detailed product briefs for all 20 items.

3. The sourcing partner leverages its network to find suitable factories for each item, negotiating prices and MOQs. For some items, they may source from the famous Yiwu Market.

4. The partner’s team handles all communication, sample consolidation, and quality inspections for each of the 20 product lines.

5. They consolidate all the finished goods from the various factories into a single container shipment, simplifying logistics and customs for the startup.

6. The startup has one point of contact and receives one consolidated invoice, allowing them to focus on launching their website and marketing campaigns. Their partner essentially provides a full suite of sourcing services China.

Many companies are realizing that the choice isn’t always binary. A hybrid approach to the indirect sourcing vs direct sourcing dilemma is often the most strategic path.

A company might use direct sourcing for its core, high-volume “A” products where control and cost are paramount. For its “B” and “C” products, which may be lower volume or more commoditized, it might use an indirect sourcing model to save time and administrative effort. This allows the company to focus its valuable in-house resources on the relationships that matter most, while still benefiting from the efficiency and flexibility of the indirect model for less critical parts of its portfolio.

The decision between direct vs indirect sourcing is a strategic one with long-term consequences. There is no single correct answer; the optimal choice depends entirely on your company’s specific context. To make an informed decision, you need to conduct a thorough self-assessment of your business’s capabilities, priorities, and goals.

Ask yourself the following questions, and answer them honestly. Your answers will point you toward the most suitable sourcing model.

1. What is the Nature of Your Product?

* Is it technically complex or require proprietary technology? (e.g., medical devices, high-end electronics). If yes, the need for control pushes you toward direct sourcing.

* Is quality a critical brand differentiator? (e.g., luxury goods, children’s products). If yes, the hands-on quality management of direct sourcing is preferable.

* Are you sourcing a standard, off-the-shelf product? (e.g., promotional items, standard components). If yes, the convenience of indirect sourcing is highly attractive.

* Are you sourcing a wide variety of different products? If yes, the consolidation benefits of indirect sourcing are a major advantage.

2. What is Your Business Scale and Volume?

* Are your order volumes very large? If yes, the per-unit cost savings of direct sourcing will likely justify the overhead.

* Are you a startup or SME with limited order volumes? If yes, the lower MOQs and minimal overhead of indirect sourcing make it the more viable option.

3. What are Your In-House Resources and Expertise?

* Do you have an experienced procurement team? Do they have experience in international trade, contract law, and logistics? If yes, you are well-equipped for direct sourcing.

* Do you have team members who can travel internationally for factory audits and relationship management? If yes, you can support a direct sourcing model.

* Is your team small and focused on other areas like marketing and sales? If yes, you should strongly consider indirect sourcing to avoid stretching your team too thin.

4. What is Your Risk Tolerance?

* Are you comfortable assuming direct legal and financial liability for your supply chain? If yes, direct sourcing is a possibility.

* Do you want to minimize your direct exposure to the risks of overseas manufacturing? If yes, the risk-buffering role of an intermediary in indirect sourcing is a significant benefit.

5. What are Your Strategic Priorities?

* Is building long-term, collaborative partnerships with manufacturers a key part of your strategy for innovation? If yes, direct sourcing is the only way to achieve this.

* Is speed to market and operational agility your top priority? If yes, leveraging the existing infrastructure of a sourcing agent via indirect sourcing can get you there faster.

* Is minimizing upfront investment and fixed overhead your main financial goal? If yes, indirect sourcing is the clear winner.

It’s important to recognize that choosing indirect sourcing is not an admission of weakness; it is a strategic decision to leverage external expertise. A high-quality sourcing partner like Maple Sourcing is not just a middleman; they are a strategic enabler. They provide the on-the-ground infrastructure, market intelligence, and operational excellence that can level the playing field for businesses of all sizes. They allow you to access the benefits of sourcing from China without having to build a procurement empire from scratch.

Even for companies pursuing a direct sourcing model for their main products, a sourcing agent can be an invaluable partner for specific tasks, such as conducting an independent, third-party factory audit or managing the logistics for a particularly complex shipment.

The direct vs indirect sourcing debate is not about choosing a “better” model in the absolute sense, but about selecting the “right” model for your specific business context. The direct and indirect sourcing difference lies in a trade-off between control and convenience, cost and complexity, risk and resources.

Direct sourcing offers unparalleled control, the potential for the lowest unit costs, and the opportunity for deep, innovative partnerships. It is the realm of large, established companies with the scale and expertise to manage a global supply chain directly. It is a resource-intensive path that, when executed well, can create a formidable and lasting competitive advantage.

Indirect sourcing provides a streamlined, lower-risk, and highly efficient pathway to global manufacturing. By leveraging the networks and expertise of intermediaries like sourcing agents, it makes sourcing from powerhouse nations like China accessible to businesses of all sizes. It is the ideal choice for startups, SMEs, and companies that prioritize agility and wish to focus their internal resources on their core competencies rather than on the complexities of procurement.

Ultimately, your sourcing strategy must be a living part of your business plan. It should be reviewed and adapted as your company grows, as your product lines evolve, and as the global market shifts. Whether you embark on the direct path, the indirect path, or a strategic hybrid of the two, the goal remains the same: to build a resilient, reliable, and cost-effective supply chain that supports your business objectives. The key is a clear-eyed assessment of your own capabilities and a strategic vision for how your procurement practices will help you win in the marketplace. For those looking to explore their options further, a great place to start is by understanding the good practices for importing products from China.