The trade relationship between China and the United States is one of the most significant economic forces shaping the modern world. For the last decade, a vast and continuous flow of goods from Chinese factories has supplied American consumers and industries, shaping market trends, influencing business strategies, and filling the shelves of countless retail stores. Understanding the landscape of these imports is crucial for any entrepreneur, procurement manager, or business owner looking to tap into the immense potential of global sourcing. The list of top imports from China to US is not merely a collection of products; it represents a complex ecosystem of manufacturing prowess, logistical networks, and strategic business opportunities.

This article provides a comprehensive exploration of the highest imported products from China over the past ten years. However, this is not just a list. It is a strategic guide for businesses aiming to navigate this lucrative yet complex market. We will delve into the specific categories that dominate the import statistics, but more importantly, we will uncover the practical “how-to” of sourcing these goods. We will outline the essential steps to import goods from China, from identifying reliable suppliers and ensuring stringent quality control to managing logistics and mitigating common risks. Whether you are interested in electronics, furniture, textiles, or any of the other most common products imported from China, this guide will provide the foundational knowledge needed to build a successful and resilient international supply chain. The journey of importing is intricate, but with the right knowledge and strategy, it is a path to significant growth and competitive advantage.

The dominance of China in global manufacturing is most pronounced in the high-tech and industrial sectors. For the last decade, electronics and machinery have consistently ranked as the top items imported from China, forming the financial backbone of the trade relationship. These categories are not just about volume; they represent the pinnacle of China’s advanced manufacturing capabilities and its deeply integrated supply chains.

When analyzing the highest imported products from China, the electronics category stands in a league of its own. From the smartphones in our pockets to the computers on our desks and the smart devices that populate our homes, the “Made in China” label is ubiquitous. This dominance is not accidental but the result of decades of strategic industrial development.

The sheer scale of consumer electronics manufacturing in China is staggering. Key products that have consistently topped the import charts include:

Smartphones and Accessories: While brands like Apple are American, their flagship products are assembled in massive factory complexes in China. This extends to a colossal ecosystem of related accessories, including charging cables, power banks, protective cases, and wireless earbuds. The city of Shenzhen, in particular, is known as the world’s electronics capital.

Computers and Laptops: A significant percentage of the world’s laptops and personal computers from leading brands like Dell, HP, and Lenovo are manufactured and assembled in China. This includes all components, from motherboards and processors to memory and casing.

Televisions and Home Entertainment: The market for large-screen TVs, soundbars, and streaming devices is another area where Chinese manufacturing excels, offering a wide range of options from budget-friendly models to high-end OLED displays.

The reason for China’s leadership is a trifecta of competitive advantages: an unparalleled electronics components ecosystem, a vast pool of skilled labor, and a highly efficient, large-scale manufacturing infrastructure that can be rapidly adapted to new product lines and fluctuating global demand.

For importers, the electronics sector is incredibly lucrative but fraught with risks. The high value of the goods combined with their technical complexity makes sourcing a challenging endeavor.

Quality and Authenticity: The risk of encountering counterfeit components or poorly assembled products is significant. A batch of phones with faulty batteries or laptops with malfunctioning screens can ruin a business’s reputation. This is why a meticulous quality control process is not just recommended; it is essential. For a deeper understanding of ensuring product standards, it is beneficial to learn about manage product quality inspections.

Finding Reliable Suppliers: The market is flooded with thousands of potential suppliers, from massive, vertically integrated factories to small trading companies operating out of a single office. Differentiating between them is a critical first step. An experienced sourcing partner can conduct on-site factory audits to verify a supplier’s true manufacturing capabilities, quality control systems, and certifications (such as ISO 9001).

Non-Negotiable Quality Control: QC for electronics is a multi-stage process. It should include pre-production checks of key components (like chipsets and screens), in-process inspections to catch assembly errors early, and a final, thorough inspection of the finished goods. This final check must include functional testing, battery life analysis, port and button checks, and verification of all required safety certifications like FCC, CE, and UL.

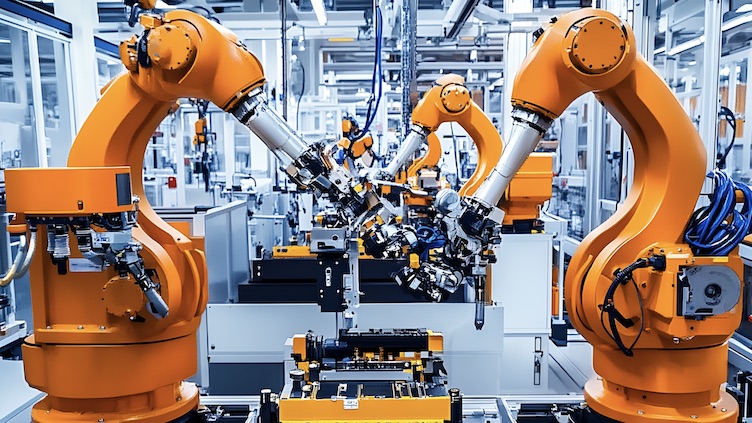

While less visible to the average consumer, the importation of industrial machinery and electrical equipment from China is a pillar of the American industrial and commercial sectors. These goods are essential for manufacturing, construction, energy, and agriculture, making them one of the top imports from China to US.

The category is incredibly diverse, encompassing everything from small workshop tools to massive industrial installations.

Industrial and Manufacturing Machinery: This includes a vast array of equipment such as CNC (Computer Numerical Control) machines, injection molding machines, laser cutters, and automated assembly line components.

Power Generation Equipment: Transformers, electric motors, generators, and switchgear are imported on a massive scale to support and expand the US power grid and industrial infrastructure.

Construction and Agricultural Equipment: While major brands dominate the heavy-duty end, a significant volume of smaller equipment, attachments, and components for construction and farming machinery is sourced from China.

Importing heavy machinery is fundamentally different from sourcing consumer goods. The financial investment is higher, the technical specifications are more complex, and the consequences of failure are more severe.

Intensive Supplier Vetting: The first of the steps to import goods from China in this category is an exhaustive supplier vetting process. This goes beyond a standard audit. It requires a technical assessment of the factory’s engineering capabilities, their understanding of US safety standards (like OSHA requirements), and their track record. Case studies and references from other international buyers are invaluable.

Logistical Hurdles: Managing the shipping for oversized or overweight machinery is a specialized field. It requires expertise in flat-rack or open-top containers, secure lashing and crating, and inland transportation. Customs clearance can also be more complex, often requiring detailed technical documentation and potentially higher import duties.

After-Sales Support and Spare Parts: What happens if a critical machine breaks down? Before placing an order, a clear agreement on warranty, after-sales technical support, and the long-term availability of spare parts is absolutely critical. This should be a key point of negotiation and clearly stipulated in the purchase contract. A reliable supplier will have a clear process for providing support and shipping replacement parts promptly.

Navigating this sector often requires specialized expertise. A sourcing partner with experience in industrial procurement can be instrumental in verifying technical specifications, auditing factories, and structuring a purchase agreement that protects the buyer’s long-term interests. Learn more about our specialized sourcing services.

While electronics and machinery represent the high-value end of the import spectrum, the sheer volume of everyday consumer goods imported from China is what truly demonstrates the depth of its manufacturing integration into American life. These are the most common products imported from China, found in virtually every home and retail store across the country.

From the chairs we sit on to the beds we sleep in, Chinese-made furniture and bedding have become a staple in the American home. The industry’s ability to produce a vast range of styles at competitive price points has made it a go-to for everyone from mass-market retailers to boutique design firms.

The diversity within this category is immense. It includes:

Ready-to-Assemble (RTA) Furniture: Often called flat-pack furniture, this segment is enormous, supplying major retailers with affordable and stylish options for every room in the house.

Upholstered Goods: Sofas, armchairs, and ottomans in a wide variety of fabrics and leathers are produced in massive quantities.

Case Goods: This includes wooden and composite furniture like dressers, nightstands, bookcases, and entertainment centers.

Mattresses and Bedding: From memory foam mattresses in a box to traditional innerspring models, along with pillows, duvets, and linens, China is a dominant supplier.

Outdoor and Patio Furniture: A seasonal but significant market for tables, chairs, and lounges made from materials like aluminum, wicker, and treated wood.

Importing furniture presents a unique set of challenges related to quality, safety, and logistics.

Material Verification: It is crucial to verify the materials being used. If you are paying for solid oak, you need to ensure you are not receiving rubberwood or a composite with a thin veneer. Fabric quality, foam density in cushions, and the grade of leather must all be clearly specified and inspected.

Quality Control in Production: Structural integrity is paramount. Inspections should focus on the quality of joints, the stability of the piece, the smoothness of the finish, and the absence of defects like scratches, dents, or misaligned parts. For any upholstered items, stitch quality and consistency are key.

Compliance with US Safety Standards: This is non-negotiable. Furniture sold in the US must comply with various safety regulations. For example, a chest of drawers must meet anti-tipping standards to prevent accidents. Upholstered furniture and mattresses must meet stringent flammability standards regulated by the CPSC. Verifying these certifications is a critical part of the sourcing process.

The Art of Container Consolidation: Furniture is bulky. Maximizing the space in a 40-foot shipping container is key to reducing per-unit shipping costs. An experienced logistics partner can help plan container loads, often consolidating orders from multiple suppliers into a single shipment (LCL - Less than Container Load), which is a core part of effective warehousing and logistics.

China is, without a doubt, the world’s toy factory. It is also a massive producer of sporting goods and games, making this one of the top imports from China to US by volume. The industry is fast-paced, trend-driven, and, most importantly, subject to some of the strictest safety regulations of any consumer product category.

The product range is as vast as a child’s imagination:

Dolls and Action Figures: Including all major licensed characters and generic dolls.

Construction Toys: Plastic building blocks and other construction sets.

Educational Toys: STEM-focused toys, puzzles, and learning aids.

Outdoor and Sporting Goods: Bicycles, scooters, helmets, basketballs, and home fitness equipment like yoga mats and resistance bands.

While the market is huge, the responsibility for importers is even bigger. Product safety is the number one priority.

Safety is Everything: The Consumer Product Safety Commission (CPSC) heavily regulates imported toys. Products intended for children 12 and under must have a Children’s Product Certificate (CPC) and undergo third-party testing at a CPSC-accepted lab. Key safety concerns include:

Lead and Heavy Metals: Strict limits on lead paint and other harmful metals.

Phthalates: Chemicals used to soften plastics that are restricted in children’s products.

Small Parts: Toys for young children must not contain small parts that could pose a choking hazard.

Mechanical Hazards: Sharp points, edges, and pinch points must be eliminated.

Ethical Sourcing and Supplier Audits: The toy industry is under intense scrutiny for labor practices. Many US retailers require suppliers to pass a social compliance audit, such as those conducted by the ICTI Ethical Toy Program. This ensures that the factory provides safe working conditions and fair wages.

Intellectual Property (IP) Protection: The toy industry is driven by creativity and unique designs. Protecting your IP is vital. This involves having a clear contract that states your ownership of the design and mold, and working with reputable suppliers who will not sell your product to competitors. Navigating the world of OEM and ODM manufacturing is key to understanding how to structure these relationships.

For any business looking to import toys, partnering with a sourcing agent who deeply understands safety compliance and can manage the required testing and certification is the only way to operate responsibly and avoid the catastrophic risk of a product recall.

The “Made in China” label has been synonymous with clothing and textiles for decades. This sector is a foundational element of China’s export economy and remains one of the top items imported from China. Alongside textiles, a less glamorous but equally massive category is plastics, a material that finds its way into an incredible variety of consumer and industrial goods.

From fast fashion retailers to luxury brands and workwear suppliers, a vast portion of the clothing and footwear sold in the US originates in China. The country’s textile industry is mature, sophisticated, and capable of producing an enormous range of products with varying levels of quality and cost.

The production landscape for textiles is highly segmented.

Apparel: This is the largest segment, including everything from t-shirts, jeans, and dresses to intricate outerwear and formalwear.

Footwear: Athletic shoes, casual sneakers, leather dress shoes, and boots are all produced on a massive scale.

Home Textiles: This includes bed linens, towels, curtains, and upholstery fabrics.

Technical Textiles: A growing segment that includes performance fabrics for sportswear, protective textiles for industrial use, and medical textiles.

China’s strength lies in its ability to manage the entire supply chain, from spinning yarn and weaving fabric to dyeing, printing, and final garment construction.

The fashion industry moves quickly, and importers need to be agile and detail oriented.

Minimum Order Quantities (MOQs): MOQs can be a significant hurdle for smaller brands. While large factories may require thousands of pieces per style, many smaller to medium-sized workshops are more flexible. A sourcing agent can often find suppliers willing to work with lower MOQs, making it possible for emerging brands to get started. Understanding the difference between various types of suppliers is important, as detailed in our guide on different types of supplier relationships.

The Critical Role of Samples: In fashion, samples are everything. The process typically involves multiple stages:

1. Proto Sample: The first attempt to create the garment based on a tech pack.

2. Fit Sample: To check the sizing and fit on a live model or mannequin.

3. Pre-Production Sample (PPS): A sample made with the final, bulk materials and trims. This must be approved before mass production begins.

4. Top of Production (TOP) Sample: A sample pulled from the first production run to ensure it matches the approved PPS.

- Stringent Quality Control: QC for apparel is incredibly detailed. Inspections must cover:

* Fabric Quality: Checking for flaws, correct weight, and feel.

* Colorfastness: Ensuring the dye does not bleed or fade after washing.

* Stitching: Checking for consistent stitches-per-inch, no loose threads, and secure seams.

* Sizing and Measurements: Measuring garments against the approved spec sheet to ensure sizing is consistent across the entire production run.

This is a broad, catch-all category that includes an almost infinite list of products. It’s one of the highest imported products from China by sheer volume and diversity. Plastic is cheap, versatile, and durable, making it an essential component in countless industries.

Packaging: Bottles, containers, films, and bags used to package food, cosmetics, and other consumer goods.

Household Goods: Kitchenware, storage containers, cleaning tools, and bathroom accessories.

Industrial Components: Custom-molded parts for the automotive, electronics, and medical industries.

Building Materials: Pipes, fittings, flooring, and insulation.

The key to sourcing plastics is precision. The process is highly technical, and small variations can have a big impact on the final product.

Mold Ownership and Costs: For any custom-designed product, the injection mold is the most significant upfront investment. It is absolutely critical that the purchase contract clearly states that you, the buyer, own the mold. The cost of a mold can range from a few thousand to tens of thousands of dollars, depending on its complexity and the type of steel used.

Precise Material Specification: There are hundreds of types of plastics, each with different properties. The difference between polypropylene (PP), polyethylene (PE), and acrylonitrile butadiene styrene (ABS) is immense in terms of strength, temperature resistance, and cost. Your product specifications must be exact.

Consistency is Key: The goal in plastic manufacturing is perfect replication, thousands or millions of time over. Quality control should focus on ensuring dimensional accuracy (using calipers), consistent color (matching against a Pantone reference), and a flawless finish (free from sink marks, flash, or other molding defects). This process is part of the broader strategy of B2B manufacturing sourcing.

Understanding the top imports from China to US is only the first step. The real challenge—and the key to success—lies in mastering the import process itself. For newcomers, this can seem like a daunting journey filled with unfamiliar terms and potential pitfalls. However, by breaking it down into a logical sequence of actions, the process becomes manageable. This section provides a clear framework, outlining the essential steps to import goods from China.

This foundational stage is where success or failure is often determined. Rushing this step is a common mistake.

Define Your Product with Precision: Before you can find a supplier, you need a detailed “tech pack” or specification sheet for your product. This should include materials, dimensions, colors, functions, and packaging requirements. The more detailed you are, the less room there is for error.

Identify Potential Suppliers:

Online Platforms: Sites like Alibaba are a good starting point for casting a wide net but require heavy vetting.

Trade Shows: Attending major fairs like the Canton Fair allows for face-to-face interaction.

Sourcing Agents: For most businesses, this is the most effective route. A professional sourcing partner, like Maple Sourcing, has a pre-vetted network of reliable factories and can match your specific product needs with a proven supplier. This is the core of our product sourcing service.

Conduct Due Diligence: Never take a supplier at their word. You must verify their claims. This includes checking their business license, asking for quality certifications, and, most importantly, arranging for a third-party factory audit to assess their real-world capabilities.

Once you have a shortlist of 2-3 promising suppliers, it’s time to get down to details.

Request for Quotation (RFQ): Send your detailed tech pack to the suppliers and ask for a comprehensive quote. A proper quote should include the unit price, MOQs, production lead time, and sample costs.

Negotiate Terms: The quoted price is often just a starting point. You can negotiate on price, but also on other critical terms like MOQs and payment structures. A standard payment term is 30% upfront to cover materials and 70% upon completion, after a successful pre-shipment inspection.

Order Samples: Never proceed to a bulk order without first getting a production sample. This is your chance to physically hold, test, and approve the product. Be prepared to pay for samples and the associated express shipping costs. It is a necessary investment.

With a supplier selected and a sample approved, you are ready to place your bulk order.

The Purchase Order (PO): This is your formal contract. It should reiterate all the product specifications, quality standards, pricing, payment terms, lead times, and shipping terms (Incoterms). It should be signed and stamped by both parties.

Initial Payment: Transfer the initial deposit (commonly 30%) so the supplier can purchase raw materials and begin production.

Production Monitoring: For large or complex orders, it is wise to have someone monitor the production process. This can include in-line inspections to catch problems early, rather than waiting until the entire order is complete.

This is your last chance to catch any issues before the goods are shipped and the final payment is made.

Hire a Third-Party Inspector: It is industry best practice to hire an independent inspection company or use your sourcing agent’s QC team. Do not rely on the factory’s internal QC. The inspector acts as your eyes and ears on the factory floor.

Final Random Inspection: The inspector will use a statistical sampling method (AQL - Acceptance Quality Limit) to randomly select a portion of the finished goods and inspect them against your pre-defined checklist.

Review the Inspection Report: You will receive a detailed report with photos and descriptions of any defects found. If the order passes, you can approve shipment. If it fails, the supplier must rework the defects, and a re-inspection is often necessary.

Once the goods pass inspection, it is time to arrange for shipping.

Work with a Freight Forwarder: A freight forwarder is a logistics expert who will handle the entire shipping process, from booking space on a vessel or aircraft to managing customs clearance at the destination port.

Understand Incoterms: Terms like FOB (Free On Board) and EXW (Ex Works) define who is responsible for the goods at each stage of the shipping process. Your freight forwarder can help you choose the best option.

Prepare Required Documents: Your supplier must provide a Commercial Invoice, a Packing List, and the Bill of Lading (for sea freight) or Air Waybill (for air freight). Your freight forwarder will use these, along with other required forms, to clear your goods through US Customs.

As you can see, the process is multi-faceted. A dedicated sourcing partner simplifies every stage. They find and vet the suppliers, manage negotiations and sampling, oversee production and quality control, and coordinate with the freight forwarder. This integrated approach dramatically reduces risk, saves time, and allows business owners to focus on what they do best: marketing and selling their products.

The story of the top imports from China to US over the last decade is a testament to the deep-seated and resilient nature of global supply chains. From the high-tech electronics and industrial machinery that power our economy to the furniture, toys, and clothing that shape our daily lives, the flow of goods is a constant reminder of this critical economic partnership. For American businesses, China remains an unparalleled resource for manufacturing, offering a combination of scale, skill, and infrastructure that is difficult to replicate elsewhere.

However, this comprehensive review also highlights a crucial truth: successful importing is not merely about identifying the highest imported products from China and placing an order. It is a strategic discipline. The difference between a profitable venture and a costly failure lies in the execution of the fundamental steps to import goods from China. It requires meticulous supplier vetting, unwavering commitment to quality control, astute negotiation, and a deep understanding of the intricacies of international logistics. The most successful importers are those who recognize that managing their supply chain is as important as managing any other aspect of their business.

Navigating this complex but rewarding landscape requires expertise, diligence, and often, a trusted partner on the ground. Whether you are a seasoned importer looking to optimize your supply chain or a new entrepreneur embarking on your first sourcing journey, the principles of strategic sourcing remain the same. By embracing a professional and systematic approach, you can mitigate risks, maximize value, and build a thriving business on the foundation of global trade.