In an era defined by globalization and intense market competition, the ability to source goods and services effectively from a worldwide network of suppliers is no longer a niche strategy but a fundamental pillar of corporate success. Global sourcing management has evolved from a simple cost-reduction tactic into a complex, strategic function that impacts every facet of a business, from product innovation and quality to supply chain resilience and brand reputation. For enterprises looking to thrive in this interconnected economy, mastering the art and science of the international procurement process is paramount. This involves developing a sophisticated global sourcing strategy that goes beyond transactional relationships to build a resilient and competitive global procurement and supply chain.

This comprehensive guide will explore the multifaceted world of global sourcing management. We will dissect the core components of a successful global sourcing strategy, navigate the complexities of the international procurement process, and provide actionable best practices for implementation. From the initial stages of market analysis and supplier identification to the ongoing challenges of quality control, risk management, and relationship building, this article will serve as a definitive resource for businesses aiming to unlock the immense value of sourcing from the global marketplace, with a particular focus on the dynamic landscape of sourcing from China.

Before delving into the operational mechanics, it’s crucial to understand why global sourcing management has become a strategic imperative. The modern business environment is characterized by rapid technological change, shifting consumer demands, and increasing geopolitical volatility. In this context, a well-executed global sourcing strategy provides a powerful competitive advantage.

Historically, the primary driver for global sourcing was labor arbitrage—the pursuit of lower manufacturing costs in developing economies. While cost efficiency remains a significant benefit, the strategic landscape has broadened considerably. Today’s leading companies leverage global sourcing to:

Access Innovation and Technology: Different regions of the world specialize in different technologies and manufacturing techniques. A global approach allows companies to tap into this diverse pool of innovation, accessing cutting-edge materials, components, and production processes that may not be available domestically.

Enhance Product Quality: By searching for suppliers on a global scale, businesses can identify and partner with world-class manufacturers who are leaders in their specific fields. This can lead to a significant improvement in the quality and performance of the final product.

Increase Market Agility and Speed-to-Market: A diverse and well-managed global supply base can increase a company’s agility. When new trends emerge, a business with a network of specialized suppliers can pivot more quickly to develop and launch new products, beating competitors to market.

Mitigate Supply Chain Risks: Over-reliance on a single domestic market or a small number of suppliers creates significant vulnerability. A diversified global procurement and supply chain spreads risk across different geographic regions, making the business more resilient to disruptions caused by natural disasters, political instability, or economic downturns. This concept is central to modern risk management in sourcing.

Drive Growth in New Markets: Establishing a manufacturing presence in a foreign country can often serve as a beachhead for market entry. By producing goods closer to a target consumer base, companies can reduce logistics costs, shorten delivery times, and gain valuable insights into local market preferences.

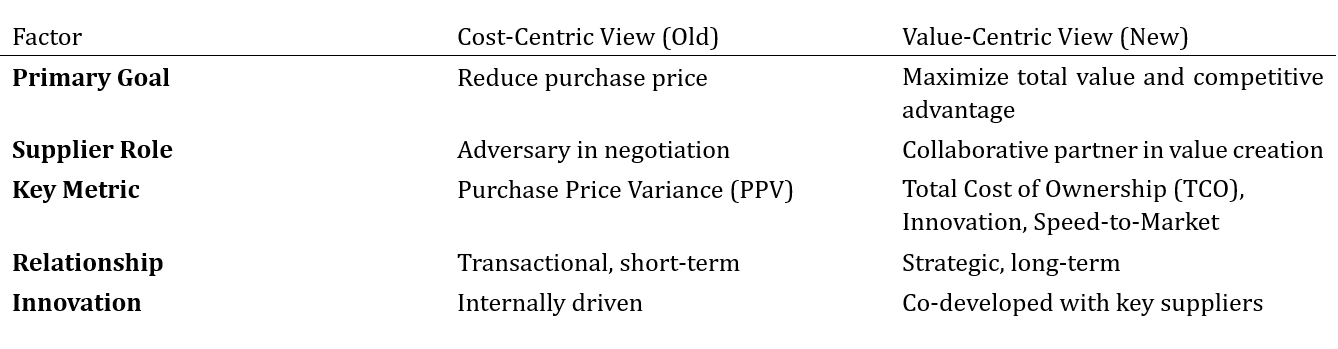

The very definition of a successful sourcing outcome has matured. While the Total Cost of Ownership (TCO) remains a critical metric, it is no longer the sole determinant of a “good” sourcing decision. The new paradigm is Total Value Contribution (TVC), which encompasses a broader set of factors:

This evolution reflects a deeper understanding that the international procurement process is not just about buying things; it’s about building a global ecosystem that enhances the company’s ability to compete and win.

The most effective global sourcing strategy is one that is deeply integrated with the overall objectives of the business. It is not an isolated procurement function but a strategic enabler.

For Businesses Competing on Innovation: The strategy will prioritize sourcing from technology hubs and building collaborative relationships with suppliers who can contribute to the research and development process.

For Businesses Competing on Brand and Quality: The focus will be on partnering with suppliers who have robust quality management systems, a proven track record of excellence, and a commitment to ethical and sustainable practices. Understanding the nuances of quality assurance in business is critical here.

For Businesses Competing on Speed and Customization: The strategic sourcing approach will favor suppliers with flexible manufacturing capabilities and proximity to key markets, enabling a faster response to changing customer needs.

A successful foray into global sourcing is not accidental; it is the result of a meticulously planned and executed global sourcing strategy. This strategy serves as the roadmap that guides every decision within the international procurement process. It’s a formal plan that outlines the objectives, processes, governance, and metrics for managing the company’s global supply base.

Effective global sourcing is a team sport. It requires the expertise and buy-in of multiple departments across the organization. The first step is to create a dedicated cross-functional team, typically including representatives from:

Procurement/Sourcing: To lead the supplier identification, negotiation, and management process.

Engineering/Product Development: To define technical specifications and evaluate supplier capabilities.

Quality Assurance: To establish quality standards and oversee inspection protocols.

Logistics/Supply Chain: To manage transportation, customs, and inventory.

Finance: To analyze costs, manage payments, and assess supplier financial stability.

Legal: To draft and review contracts and ensure compliance.

This team-based approach ensures that all facets of the sourcing decision are considered, leading to more robust and sustainable outcomes. A lack of cross-functional alignment is one of the most common reasons why sourcing initiatives fail to deliver their expected value.

Before looking outward, a company must first look inward. A thorough analysis of the company’s current spending (a “spend analysis”) is critical. This involves aggregating all procurement data, often from disparate systems (accounting, ERP, purchasing cards), into a single, clean database to understand:

- What are we currently buying?

- Who are we buying it from?

- How much are we paying?

- Are we consolidating volume with a few suppliers or is our spend fragmented?

- What are the total volumes for each category of product?

A Practical Example: Spend Analysis in Action

Imagine a mid-sized electronics company. A spend analysis might reveal that they purchase 50 different types of fasteners from 30 different suppliers. While the individual cost of each screw is low, the analysis shows that the total annual spend on fasteners is $500,000. Furthermore, the administrative cost of managing 30 separate vendors (purchase orders, invoices, payments) is significant. This insight immediately highlights an opportunity for “vendor consolidation.” By consolidating this spend with two or three strategic fastener suppliers, the company can leverage its total volume to negotiate much better pricing, simplify its administrative processes, and build stronger relationships, leading to better service and quality. This is a classic first step in any strategic sourcing initiative.

Concurrently, the team must conduct extensive external market research. This goes beyond simple Google searches. It involves:

* Porter’s Five Forces Analysis: Analyzing the bargaining power of buyers and suppliers, the threat of new entrants and substitutes, and the level of competitive rivalry in the supply market for a specific category.

* SWOT Analysis: Assessing the Strengths, Weaknesses, Opportunities, and Threats of sourcing from different regions or specific suppliers.

* Supplier Benchmarking: Comparing the capabilities, cost structures, and performance of leading suppliers in a given market.

This deep analysis provides the factual foundation upon which the entire global sourcing strategy is built.

With a clear understanding of the internal needs and external market, the team can define the specific goals for the global sourcing strategy. These goals must be SMART (Specific, Measurable, Achievable, Relevant, Time-bound). Vague goals like “improve supplier performance” are not actionable.

Examples of strategic goals include:

“Reduce the total cost of ownership for Component X by 15% within 12 months.”

“Qualify two new suppliers in Southeast Asia for Product Category Y by the end of Q3 to reduce our reliance on a single region.”

“Decrease the average production lead time for our flagship product line from 90 days to 60 days by partnering with a more technologically advanced supplier.”

“Increase supplier-led innovation by launching two new products in the next fiscal year based on technology proposed by our strategic partners.”

Alongside these goals, the team must establish the Key Performance Indicators (KPIs) that will be used to measure success. These KPIs should be cascaded down from the high-level goals. For instance, the goal of reducing TCO by 15% might be measured by KPIs such as:

* Purchase Price Variance (PPV)

* Freight & Logistics Costs as a % of Spend

* Quality Rejection Rate (PPM - Parts Per Million)

* Inventory Holding Costs.

These KPIs will form the basis of the supplier performance management system.

The strategy must outline a standardized, repeatable process for identifying, evaluating, and selecting suppliers. This is the core of strategic sourcing. A typical process, often referred to as the 7-step strategic sourcing process, includes:

Profile the Category: Deeply analyze the spend category identified earlier. Understand the technical specifications, the internal stakeholders’ requirements, and the total cost model.

Supply Market Analysis: Research the global supplier landscape. Who are the key players? What are the pricing trends? What are the risks of sourcing from different regions?

Develop the Strategy: Define the approach for sourcing the category. Will it be a competitive tender? A strategic partnership? Will you consolidate suppliers or cultivate new ones?

Select the Sourcing Process: Choose the specific method for engaging suppliers. This could be a multi-stage Request for Proposal (RFP) for a complex service, or a simple Request for Quotation (RFQ) for a standard component.

Negotiate and Select Suppliers: Conduct structured, fact-based negotiations and use a supplier scorecard to select the partners that offer the best overall value, not just the lowest price.

Implement and Integrate: Onboard the new suppliers. This is a critical step that involves communicating the new process to internal stakeholders and integrating the supplier into your systems (e.g., ERP, quality systems). A poor implementation can derail even the best strategy.

Benchmark and Track Results: Continuously monitor performance against the defined KPIs. This data feeds back into the category profile, making the strategic sourcing process a cycle of continuous improvement.

This structured process ensures that supplier selection is based on objective criteria and a comprehensive evaluation, rather than just price alone.

With a robust strategy in place, the focus shifts to execution. The international procurement process is the operational workflow for turning the strategy into reality. It’s a journey fraught with potential pitfalls, especially when sourcing from a market as complex as China.

This is arguably the most critical phase. Selecting the wrong supplier can lead to a cascade of problems, from quality defects and shipping delays to intellectual property theft.

Online B2B Marketplaces: Platforms like Alibaba, Global Sources, and Made-in-China.com are often the first stop. They provide access to millions of potential suppliers but require careful vetting to distinguish between legitimate factories and trading companies. The risks of buying from Alibaba can be significant if proper due diligence is not performed.

Industry Trade Shows: Attending major trade fairs like the Canton Fair allows for face-to-face interaction and the ability to physically inspect product samples. It’s an excellent way to gauge the scale and professionalism of potential partners.

Referrals and Networks: Leveraging your professional network can often lead to high-quality referrals.

Professional Sourcing Agents: Partnering with a sourcing agent or company is often the most efficient and secure method for businesses without a local presence. A local partner, like Maple Sourcing, can leverage their existing network of vetted suppliers, bridging language and cultural gaps. Understanding what a sourcing agent is and why it’s important is key for many importers.

Before you start evaluating, it’s helpful to create an “Ideal Supplier Profile.” This document details the essential and desirable characteristics of a partner for a specific product category.

Example Ideal Supplier Profile (for Consumer Electronics):

Essential (Non-negotiable):

* ISO 9001 certification for quality management.

* BSCI or SA8000 certification for social compliance.

* Minimum 5 years of experience manufacturing similar products.

* Dedicated in-house QC team with specific testing equipment (e.g., RoHS testers, battery cycle testers).

* Accepts 30/70 payment terms.

* English-speaking sales and engineering contact.

Desirable (Preferred):

* Experience exporting to the target market (e.g., North America, EU).

* In-house product design and engineering support.

* Proximity to a major port (e.g., Shenzhen, Shanghai).

* Experience with specific retailers’ compliance requirements (e.g., Walmart, Amazon).

Using this profile as a checklist during the vetting process adds structure and objectivity. The vetting process itself should be multi-layered:

Initial Screening (Request for Information - RFI): Send a formal RFI to potential suppliers to gather basic information. Use your Ideal Supplier Profile to quickly screen out non-compliant candidates.

Detailed Evaluation (Request for Quotation - RFQ): For promising candidates, issue a detailed RFQ. The professionalism, detail, and timeliness of their response are important evaluation criteria in themselves.

Factory Audits: A physical audit of the factory is non-negotiable for any significant partnership. An audit is not just a tour; it’s a deep dive. For an electronics factory, an auditor would check:

- ESD (Electrostatic Discharge) Controls: Are workers grounded? Is flooring and furniture anti-static?

- Component Traceability: Can they trace a specific component on a PCB back to its original reel and supplier?

- Equipment Calibration: Are soldering irons, testing equipment, and torque drivers calibrated regularly?

- Workmanship Standards: Do they have clear, documented standards (e.g., IPC-A-610) for soldering and assembly? A typical supplier quality audit checklist can be customized for your specific industry.

- Sample Evaluation: Request pre-production samples. Don’t just look at them; test them rigorously. For a consumer electronic device, this would involve functional testing, battery life testing, drop tests, and environmental testing. This is a critical step to verify that the supplier can meet your requirements.

Effective negotiation in a global context requires cultural awareness and a focus on building a mutually beneficial agreement.

Price: While important, it should not be the only consideration. Focus on the total cost of ownership.

Payment Terms: A standard arrangement is a 30% down payment and 70% upon completion or after a successful final inspection. Avoid paying 100% upfront.

Minimum Order Quantity (MOQ): Negotiate an MOQ that aligns with your sales forecasts and inventory strategy.

Production Lead Time: Agree on a realistic timeline from order placement to shipment. Be sure to clarify if this includes time for raw material procurement.

Incoterms: Clearly define shipping terms (e.g., FOB, EXW) to establish who is responsible for logistics costs and risks at each stage. Understanding the difference between FOB and EXW is fundamental for importers.

Cultural Considerations in Negotiation: In many Asian cultures, including China, building a relationship (guanxi) is an important precursor to business. The negotiation process may be less direct and take longer than in Western cultures. Rushing the process or using overly aggressive tactics can be counterproductive. The goal is to achieve a win-win outcome that forms the basis of a long-term partnership.

A detailed, bilingual (English and Chinese) contract is your most important legal protection. It should be enforceable in China. Key clauses to expand upon include:

Detailed Product Specifications: This should be an appendix to the contract, including all CAD drawings, material specifications (with approved manufacturers if necessary), color Pantone numbers, and approved “golden samples.”

Quality Standards and Inspection Criteria: Explicitly reference your quality control checklist and the AQL standards you will use for inspection.

Tooling and Mold Ownership: If you are paying for tooling, the contract must clearly state that you are the sole and exclusive owner of the mold, and it cannot be used for any other customer.

Intellectual Property (IP) Protection: Include a specific NNN (Non-Disclosure, Non-Use, Non-Circumvention) clause that is separate from a Western-style NDA and is enforceable in Chinese courts.

Raw Material Price Fluctuation: In volatile commodity markets, suppliers may want a clause that allows for price changes. This should be tightly controlled, linking any price increase to a specific, verifiable commodity index and only applying to future orders.

Penalties for Delays and Defects: Outline the consequences. For example, a 1% penalty on the order value for each week of delay, and a clear process for how defective goods will be handled (e.g., rework at the supplier’s cost, replacement, or credit).

Dispute Resolution Clause: Specify the governing law and jurisdiction. Often, arbitration in a neutral location like Hong Kong or Singapore is a preferred option.

Once the order is placed, active management of the production process is essential to ensure a successful outcome.

Quality is not something that can be inspected into a product at the end; it must be built in from the beginning. A multi-stage inspection process, managed through a detailed Quality Control Checklist, is a best practice in global procurement and supply chain management.

The Quality Control Checklist: This is a detailed document that you (or your inspector) will use during inspections. It translates your product specifications into a series of concrete checkpoints. For a piece of furniture, it might include:

* Confirming wood species and moisture content.

* Measuring all dimensions against the technical drawing, with specified tolerances.

* Checking the color finish against an approved sample under specific lighting conditions.

* Performing assembly tests to ensure all parts fit together correctly.

* Conducting load bearing and stability tests.

* Checking for any cosmetic defects like scratches, dents, or paint drips.

The inspection itself follows a statistical sampling method known as AQL (Acceptable Quality Limit). The inspector doesn’t check every single unit, but a random sample based on the lot size and pre-agreed AQL levels (e.g., AQL 2.5 for major defects, AQL 4.0 for minor defects). If the number of defects found in the sample is below the threshold, the lot passes.

Pre-Production Inspection (PPI): An inspector visits the factory before production begins to verify that the Quality Control Checklist is understood and that the correct raw materials, components, and tooling are ready for production.

During Production Inspection (DUPRO): The inspector returns when 15-20% of the production run is complete. This is the most effective time to catch systemic problems. If an issue is found on the production line, it can be corrected before thousands of defective units are produced.

Pre-Shipment Inspection (PSI): This is the final and most common inspection. An inspector uses the Quality Control Checklist and AQL standards to conduct a final check of the finished, packaged goods. This is your last chance to catch any issues before the products are shipped and payment is finalized. The different types of inspection in production management each play a vital role.

Many companies choose to work with third-party quality control services to perform these inspections, ensuring an objective and professional assessment.

The modern global procurement and supply chain is a complex ecosystem that is constantly exposed to potential disruptions. Building resilience is a core component of an advanced global sourcing strategy. This means designing a supply chain that can anticipate, withstand, and recover from shocks.

The foundation of a resilient supply chain is strong supplier relationships. Strategic sourcing is not just about finding the cheapest supplier; it’s about identifying the best partners and cultivating long-term, collaborative relationships.

Moving Beyond Transactional: The traditional, adversarial model of squeezing suppliers on price is being replaced by a more collaborative approach. By treating suppliers as partners, companies can unlock significant value in the form of innovation, preferential treatment, and proactive problem-solving.

Segmentation: Not all suppliers require the same level of engagement. A best practice is to segment suppliers (using a model like the Kraljic Matrix) into categories (e.g., Strategic, Leverage, Bottleneck, Non-Critical) and tailor the relationship management approach accordingly. Strategic partners warrant executive-level engagement, joint business planning, and a high degree of transparency. The different types of supplier relationships require different management styles.

Performance Management: A structured supplier performance management program, based on the KPIs defined in the strategy, is essential. Regular business reviews (Quarterly Business Reviews or QBRs for strategic partners) provide a forum for discussing performance, resolving issues, and aligning on future goals. This two-way dialogue is also an opportunity for the supplier to provide feedback to you on how you can be a better customer (e.g., by improving forecast accuracy). For a deeper understanding, one can refer to the knowhow about supplier relationship management.

Supplier Development: The most advanced form of SRM involves actively working to improve a supplier’s capabilities. This can include joint process improvement projects, sharing best practices in lean manufacturing, or providing technical support. A more capable supplier base is a direct competitive advantage.

A proactive approach to risk management is critical. This involves identifying potential risks throughout the global procurement and supply chain and developing mitigation plans. This is not a one-time exercise but a continuous process.

Geopolitical and Trade Risks: The rise of tariffs and trade disputes has highlighted the risks of concentrating sourcing in a single country. Many companies are now adopting a “China Plus One” strategy, diversifying their supply base to include other regions like Vietnam, Mexico, or India. This requires significant long-term investment but is a powerful mitigation strategy.

Supplier Viability Risk: Continuously monitor the financial health of critical suppliers to get early warnings of potential insolvency. For key partners, you might request periodic financial statements. Another warning sign can be a sudden increase in staff turnover.

Logistics and Transportation Risks: Port congestion, container shortages, and shipping route disruptions have become common. Mitigation strategies include:

- Cargo Insurance: Always insure your shipments. Standard carrier liability is very limited.

- Multi-modal Shipping: Explore options that combine sea, air, and land transport to create more resilient routes.

- Working with a reliable freight forwarder: A good freight forwarder can provide visibility and help navigate disruptions. Understanding the trade-offs in logistics and supply chain management is crucial for effective planning.

Intellectual Property Risk: In addition to strong contracts, it’s vital to protect your product idea when you outsource from China by registering trademarks and patents in the local market. Another practical strategy is the “black box” approach, where critical components are sourced from a separate, trusted supplier and only delivered to the final assembly factory, so no single supplier has the complete design.

Technology is a powerful enabler of a more efficient and resilient global procurement and supply chain. It transforms manual, error-prone processes into streamlined, data-driven workflows.

Supply Chain Visibility Platforms: These tools provide real-time tracking of shipments, allowing for more proactive management of logistics and better communication with customers.

Procure-to-Pay (P2P) Systems: These platforms (often part of a larger ERP system like SAP or Oracle) automate the procurement workflow, from purchase order creation and approval to invoice matching and payment, reducing administrative overhead and improving data accuracy.

Quality Management Systems (QMS): Digital QMS platforms (like Veeva or MasterControl) allow companies to centralize quality data, manage supplier compliance documentation, track inspection results, and manage corrective action plans with suppliers in real-time.

Supplier Relationship Management Platforms: Specialized SRM software helps manage supplier information, track performance scorecards, and oversee relationship management activities, providing a “single source of truth” for all supplier-related data.

AI in Procurement: Artificial intelligence in procurement is being used to analyze spend data to identify new savings opportunities, monitor external data sources (like news and social media) to predict supply chain disruptions, and even automate negotiations for non-critical items.

The landscape of global sourcing management is in a state of constant evolution. The simple labor-cost-driven model of the past is giving way to a more nuanced and strategic sourcing approach. The future of the international procurement process will be defined by several key trends: an increased focus on resilience and agility, a greater emphasis on sustainability and ethical sourcing (ESG), and the pervasive impact of digitalization and automation. Companies that fail to adapt to this new reality risk being left with a brittle, opaque, and uncompetitive supply chain.

Successfully navigating this complex environment requires a sophisticated global sourcing strategy that is both comprehensive in its planning and flexible in its execution. It demands a shift in mindset from viewing procurement as a purely cost-focused function to seeing it as a powerful driver of competitive advantage. The ability to build a truly integrated global procurement and supply chain, founded on strong supplier partnerships and enabled by technology, will be the hallmark of the most successful companies in the years to come.

For businesses looking to embark on or optimize their global sourcing journey, the path can seem daunting. The challenges are real, but the rewards are immense. By adhering to the principles of strategic sourcing, investing in rigorous processes, and cultivating collaborative relationships, companies can unlock a world of opportunity. Partnering with experts can significantly de-risk and accelerate this journey. To learn more about how a dedicated sourcing partner can help you build a world-class supply chain, explore our comprehensive sourcing services.