In the globalized marketplace, the ability to bring a unique product vision to life is a cornerstone of competitive advantage. For entrepreneurs and established businesses alike, the journey from a simple concept to a tangible, market-ready item is both thrilling and fraught with challenges. For decades, China has stood as the undisputed global leader in manufacturing, evolving from a producer of mass-market goods to a sophisticated hub for high-quality, bespoke production. Engaging in custom product manufacturing in China offers a powerful pathway to innovation, scalability, and cost-effectiveness that is unparalleled elsewhere in the world. This comprehensive guide will navigate the intricate landscape of creating custom products in China, providing a detailed roadmap for success, from initial design to final delivery.

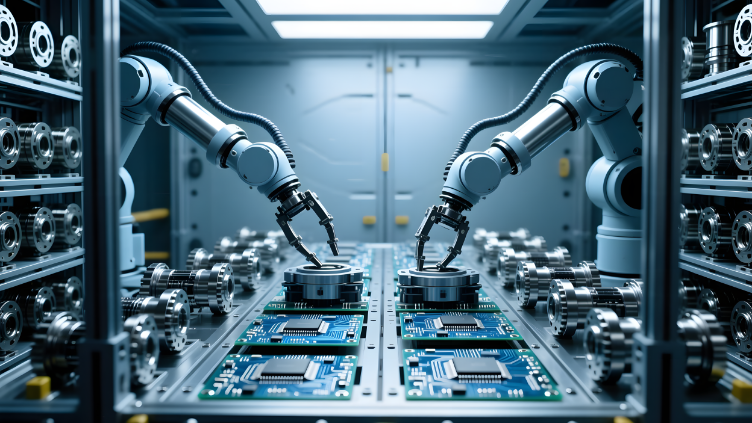

The decision to manufacture a custom product is a significant strategic move. It allows a brand to differentiate itself, control quality down to the smallest detail, and build a unique value proposition that cannot be easily replicated. However, this process demands a deep understanding of the manufacturing ecosystem, a meticulous approach to supplier management, and a robust strategy for mitigating risks. Whether you are looking to create intricate custom plastic parts, undertake complex custom metal fabrication China, or develop specialized components like a custom wire harness, China’s vast industrial network offers a solution. This guide will explore the critical steps, potential pitfalls, and expert strategies required to successfully leverage the power of Chinese manufacturing, turning your unique product ideas into a commercial reality. We will delve into finding the right custom manufacturing companies, managing the development process, ensuring stringent quality control, and navigating the complexities of international logistics.

The phrase “Made in China” has undergone a profound transformation. Once synonymous with low-cost, high-volume production, it now represents a dynamic and highly capable manufacturing ecosystem that excels in customization and technological innovation. The strategic reasons for choosing China for custom product manufacturing extend far beyond simple cost savings.

China’s industrial infrastructure is arguably the most comprehensive in the world. Decades of state-led investment and market-driven growth have created a dense network of factories, suppliers, logistics providers, and skilled labor. This ecosystem is not just vast; it is deeply interconnected. For any given custom product, the raw materials, specialized components, finishing services, and packaging are often located within a close geographical radius. This clustering, particularly in key manufacturing hubs, dramatically reduces lead times and logistical complexities. For a deeper understanding of these industrial zones, it’s helpful to read an introduction to key manufacturing hubs of China. This integrated supply chain is a primary reason why China can take a complex custom design from prototype to mass production faster than almost any other nation.

While labor costs in China have risen, the country maintains a significant advantage when considering the total cost of ownership. This is a result of several factors:

* Economies of Scale: The sheer volume of production allows for lower raw material costs.

* Efficiency: Mature processes and a competitive landscape drive factories to be highly efficient.

* Tooling and Molds: China is exceptionally competitive in the creation of molds and tooling, which are often the most significant upfront investments in custom product manufacturing, particularly for custom plastic parts. The cost to create a high-quality injection mold can be a fraction of what it would be in Europe or North America.

* Logistical Efficiency: The well-developed shipping and port infrastructure ensures that getting products out of the country is streamlined and cost-effective.

When businesses properly analyze all factors, from development to delivery, China often presents the most financially viable option for custom projects.

The depth of manufacturing expertise in China is staggering. For virtually any product category, there are factories that have been specializing in that specific area for years, if not decades. This experience is invaluable in custom product manufacturing. An experienced factory can often provide critical feedback on a design, suggesting modifications for manufacturability that can improve the product’s quality, durability, and cost-effectiveness. This collaborative approach, where the manufacturer becomes a partner in the development process, is a hallmark of successful custom projects. Whether it’s a specific polymer for an injection-molded part or a particular welding technique for custom metal fabrication China, the specialized knowledge resides within these factories.

Chinese manufacturers are renowned for their adaptability. They are accustomed to working with international clients who have a wide range of requirements, from small startups to large multinational corporations. This has fostered a culture of flexibility. While Minimum Order Quantities (MOQs) are a standard part of the business, many factories are willing to negotiate, especially for promising new products. They are often able to quickly scale production up or down in response to market demand, providing a level of agility that is crucial for new product launches. This flexibility is a key advantage when navigating the uncertainties of bringing a novel product to market.

The single most critical factor in the success of your custom product manufacturing project is the partner you choose. The right factory will act as a cornerstone of your business, while the wrong one can lead to endless frustration, financial loss, and potentially the failure of your product. Finding and thoroughly vetting potential custom manufacturing companies is a multi-stage process that requires diligence, skepticism, and a clear strategy.

Your search for a manufacturing partner will likely begin online, but it shouldn’t end there. A multi-pronged approach is most effective.

B2B Online Marketplaces: Platforms like Alibaba, Made-in-China.com, and Global Sources are the default starting point for many. They are vast directories containing millions of supplier profiles.

- Pros: An enormous selection, powerful search filters, and a direct line of communication for initial inquiries.

- Cons: The signal-to-noise ratio can be low. It is filled with trading companies posing as factories, and verifying a supplier’s claims is a significant challenge. It’s important to understand the platform; for instance, knowing what’s the difference between Alibaba and AliExpress is fundamental. Even with verification tiers, you must conduct your own due diligence.

Industry Trade Shows: Attending major trade fairs like the Canton Fair, East China Fair, or industry-specific exhibitions (e.g., for electronics or textiles) offers an invaluable opportunity to meet suppliers face-to-face.

- Pros: You can physically inspect product samples, gauge the professionalism of the sales team, and have in-depth conversations about your project.

- Cons: This approach requires a significant investment in time and travel. Furthermore, some of the best factories, already busy with existing clients, may not exhibit at these shows.

Professional Sourcing Companies: For many businesses, this is the most secure and efficient route. A reputable sourcing company acts as your on-the-ground team. They have an existing network of vetted factories and a deep understanding of the local manufacturing landscape.

- Pros: They bridge language and cultural gaps, handle the entire vetting process, and manage the project from start to finish. They can often find better-quality factories that are not on the major B2B platforms.

- Cons: This service comes at a cost, typically a percentage of the order value. However, this cost is often offset by better pricing, reduced risk, and fewer costly mistakes.

Once you have a shortlist of potential suppliers, the real work begins. Never take a supplier’s claims at face value.

Initial Screening & Communication: Send a detailed Request for Quotation (RFQ) to your shortlisted suppliers. Your RFQ should be as specific as possible, including design files (CAD), material specifications, quantity breaks, packaging requirements, and target pricing. The quality and professionalism of their response is your first filter. Do they ask intelligent questions? Is their pricing breakdown clear? How is their English proficiency?

Background Verification: Ask for copies of their business license, quality certifications (e.g., ISO 9001, IATF 16949 for automotive), and any relevant product test reports. A legitimate factory will provide these without hesitation. A sourcing partner can help verify these documents through official channels.

Factory Audits: For any serious custom product manufacturing project, a factory audit is non-negotiable. An audit provides a real-world assessment of their capabilities and professionalism. If you cannot visit in person, you must hire a third-party inspector or rely on your sourcing partner to conduct it. A comprehensive audit, as detailed in guides on why factory audits are key to your success, should cover:

- Scale and Legitimacy: Is it a real factory or just a small workshop or trading office?

- Quality Management System (QMS): Do they have documented quality control processes? How do they handle incoming materials, in-process checks, and final inspections?

- Production Capabilities: Is their equipment suitable for your product? Is it well-maintained? Do they have the capacity to handle your order volume?

- Social Compliance: Does the factory provide a safe and ethical working environment? This is increasingly important for brand reputation.

Sample and Prototype Evaluation: The ultimate test of a factory’s capability is the quality of their work. Before committing to mass production, you must go through a prototyping and sampling phase. Evaluate the samples not just for aesthetics but for dimensional accuracy, material correctness, and functionality.

Building a strong relationship with your supplier is paramount. It’s wise to understand the different types of supplier relationships you need to know to set the right tone from the beginning. A partnership approach, rather than a purely transactional one, will yield far better results in the long run.

The path from a product idea to a “golden sample”—the final, approved prototype that serves as the benchmark for mass production—is a critical and iterative phase in custom product manufacturing. This is where your vision is translated into a physical object, and it requires close collaboration with your chosen manufacturer.

Before any physical work begins, you must provide the factory with a comprehensive “tech pack.” This is a set of documents that leaves no room for ambiguity. It should include:

3D CAD Files: The universal language of manufacturing. Formats like .STEP, .IGS, or .X_T are standard.

2D Engineering Drawings: These supplement the 3D files with critical information like dimensions, tolerances, material specifications, and required finishes.

Bill of Materials (BOM): A list of all components and raw materials required for the product.

Color & Finish Specifications: Use universal standards like Pantone (for colors) or specify the exact texture and finish required.

Upon receiving your tech pack, a good manufacturer will perform a Design for Manufacturability (DFM) analysis. This is an invaluable service where their engineers review your design and provide feedback on how to optimize it for their production processes. They might suggest minor changes to wall thickness to prevent sink marks in custom plastic parts, or recommend a different alloy for easier machining in custom metal fabrication China. This collaborative step can significantly improve quality and reduce costs.

Before you send your detailed designs to any manufacturer, you must take steps to protect your intellectual property. This is a major concern for anyone outsourcing production. A multi-layered approach is essential, and you can find detailed guidance on how to protect your product idea when you outsource from China.

NDA Agreement: In China, a standard Non-Disclosure Agreement (NDA) is required. This should be drafted by a lawyer specializing in Chinese IP law, written in Chinese, and be enforceable in a Chinese court. It explicitly prevents the factory from using your idea themselves, sharing it with others, or bypassing you to sell to your customers.

Patents and Trademarks: If your product has unique, inventive features, consider filing for a patent in China. At a minimum, you should register your brand name and logo as trademarks in China. This is a defensive measure to prevent others from squatting on your brand name.

For many custom products, especially those involving injection molding or die casting, the creation of tooling (molds) is the most significant upfront investment and the longest part of the lead time.

Ownership: Your contract must clearly state that you are the sole owner of the mold, even though it is housed at the factory.

Material and Lifespan: The type of steel used for the mold (e.g., P20, H13, S136) will determine its lifespan (number of shots) and the quality of the finished parts. Discuss this with your supplier based on your expected production volume.

First Shots (T1 Samples): Once the mold is complete, the factory will produce the first samples, known as T1 samples. These are rarely perfect.

The T1 samples are sent to you for evaluation. You will meticulously inspect them against your tech pack, checking every dimension, feature, and finish. You will then provide detailed feedback to the factory, noting any required modifications. This may involve minor adjustments to the mold (tooling modifications) or changes to the production parameters.

This iterative process of feedback and refinement may require several rounds of samples (T2, T3, etc.). It continues until you receive a sample that perfectly matches your requirements in every aspect. This final, perfect sample is the “golden sample.” You will sign and approve it, and it will serve as the physical standard against which all mass-produced units will be compared during quality control inspections. This process, while sometimes lengthy, is absolutely essential to ensure the final product meets your expectations.

Plastic is one of the most versatile materials in modern manufacturing, and China is the world’s foremost expert in producing high-quality, cost-effective custom plastic parts. From simple enclosures to complex, high-precision components, the possibilities are nearly limitless. Understanding the key processes and materials is crucial for any business looking to source plastic parts.

While there are many ways to form plastic, two processes dominate the landscape for custom product manufacturing:

Injection Molding: This is the most common process for mass-producing plastic parts. It involves injecting molten plastic under high pressure into a custom-made metal mold (the tooling).

- Advantages: Extremely high precision, excellent surface finish, low cost per part at high volumes, and a vast range of available materials.

- Disadvantages: The primary drawback is the high upfront cost of the mold, which can range from a few thousand to tens of thousands of dollars, depending on its complexity and size. The lead time to create the mold is also significant, often taking 4-8 weeks.

- Best for: High-volume production runs (typically thousands to millions of parts) where the cost of the mold can be amortized over many units.

3D Printing (Additive Manufacturing): This process builds a part layer by layer directly from a CAD file. It has revolutionized prototyping and is increasingly used for low-volume production.

- Advantages: No tooling costs, very fast turnaround for prototypes (days instead of weeks), and the ability to create highly complex geometries that are impossible to mold.

- Disadvantages: Higher cost per part compared to injection molding, slower for mass production, and the material properties and surface finish may not be as good as molded parts.

- Best for: Prototyping, very low-volume production runs, and creating parts with extremely complex internal structures.

The choice of material is critical to the functionality, appearance, and cost of your part. Here are a few of the most common plastics used in custom product manufacturing:

ABS (Acrylonitrile Butadiene Styrene): A strong, rigid, and cost-effective thermoplastic. It’s known for its impact resistance and good surface finish. Think of LEGO bricks, keyboard caps, and electronic enclosures.

PC (Polycarbonate): A very tough and transparent plastic with excellent impact strength and heat resistance. Used for things like safety glasses, reusable water bottles, and electronic device screens.

PP (Polypropylene): A flexible, lightweight, and chemically resistant plastic. It’s very common and inexpensive. Used for food containers, living hinges (like on a bottle cap), and automotive parts.

Nylon (PA): A strong, durable plastic with excellent wear resistance. Often used for gears, bearings, and other mechanical parts.

TPE/TPU (Thermoplastic Elastomer/Urethane): A class of rubber-like plastics that can be processed like thermoplastics. They are used for soft-touch grips, flexible phone cases, and seals.

When searching for custom manufacturing companies for plastic parts, specialization is key.

Look for Mold-Making Expertise: A factory that makes its own molds in-house has far more control over the quality and timeline of your project than one that outsources this critical step. Ask to see their tooling workshop during your audit.

Check Their Equipment: The size and tonnage of their injection molding machines will determine the size of the parts they can produce. Ensure their equipment is modern and well-maintained.

Material Handling: How do they store and handle raw plastic resin? Proper drying of the resin before molding is critical to prevent defects in the final parts.

Experience in Your Industry: A factory that specializes in medical devices will have different quality standards and expertise than one that makes toys. Find a supplier with a portfolio of products similar to yours.

The process of creating custom plastic parts is a science. It requires a deep understanding of material properties, mold design, and process parameters. Partnering with an experienced manufacturer is the best way to ensure a high-quality outcome.

For products requiring strength, durability, and precision, metal is the material of choice. China’s capabilities in custom metal fabrication China are world-class, offering a vast array of processes to shape and finish metal parts to exact specifications. From consumer electronics housings to industrial machinery components, Chinese factories can deliver high-quality metal parts at a competitive cost.

“Metal fabrication” is a broad term that encompasses many different technologies. Here are some of the most common processes used in custom product manufacturing:

CNC (Computer Numerical Control) Machining: This is a subtractive process where a block of metal is shaped by a computer-controlled cutting tool. It is known for its extremely high precision and ability to create complex shapes.

- Processes: Includes CNC milling (for complex 3D shapes) and CNC turning (for cylindrical parts).

- Advantages: Very high accuracy and tight tolerances, excellent surface finish, and suitable for a wide range of metals (aluminum, steel, brass, titanium, etc.).

- Best for: High-precision parts, prototypes, and low-to-medium volume production.

Sheet Metal Fabrication: This involves cutting, bending, and assembling parts from flat sheets of metal.

- Processes: Laser cutting or punching (for cutting shapes), press braking (for bending), welding, and assembly.

- Advantages: Cost-effective for producing enclosures, brackets, and chassis. Strong and lightweight parts.

- Best for: Housings for electronics, server racks, automotive body parts, and structural components.

Casting: This process involves pouring molten metal into a mold to create a part.

- Processes: Die casting (for high-volume, high-precision parts, typically from non-ferrous metals like aluminum or zinc) and sand casting (for large, complex parts, often from iron or steel).

- Advantages: Can create very complex internal and external shapes, and is highly efficient for mass production.

- Best for: Engine blocks, gearboxes, and complex housings where machining would be too expensive.

Welding and Assembly: The process of joining multiple metal components together. A factory’s skill in welding is a critical indicator of its quality, especially for structural products.

The final finish of a metal part is crucial for both its appearance and its durability. Common finishing options in China include:

Anodizing: An electrochemical process for aluminum that creates a hard, durable, and corrosion-resistant surface. It can also be used to add color.

Powder Coating: A dry finishing process where a powder is electrostatically applied to a part and then cured with heat. It creates a very durable and uniform finish that is more robust than conventional paint.

Plating: Applying a thin layer of another metal (like chrome, nickel, or zinc) to the surface to improve corrosion resistance or aesthetics.

Polishing and Brushing: Mechanical processes to create a specific surface texture, from a mirror-like polish to a brushed satin finish.

When looking for a partner for custom metal fabrication China, your vetting process should be particularly rigorous.

Process Specialization: Few factories excel at all metal processes. A factory specializing in high-precision CNC machining is very different from a heavy industrial sand casting foundry. Identify the primary process your product requires and find a specialist in that area.

Quality Control and Metrology: How do they measure and verify part dimensions? Look for a dedicated, climate-controlled QC room with advanced measuring equipment like Coordinate Measuring Machines (CMMs), calipers, and micrometers.

Material Certification: The factory must be able to provide material certifications for the specific alloy they are using to ensure it meets your specifications. Material traceability is key.

Review Past Work: Ask to see samples of similar parts they have produced. Pay close attention to the quality of the machining, the consistency of the finish, and the precision of any welded joints.

The world of custom metal fabrication China is diverse. Taking the time to find a true specialist will pay significant dividends in the quality and reliability of your final product.

Often hidden inside a product’s casing, the custom wire harness is the critical nervous system that allows all the electronic components to communicate and receive power. While it may seem like a simple bundle of wires, manufacturing a reliable and safe wire harness is a highly specialized and detail-oriented process. For any electronic product, from consumer gadgets to industrial machinery, the quality of the custom wire harness is paramount to the product’s overall safety and functionality.

A wire harness is an organized set of wires, terminals, and connectors that are bound together to transmit signals or electrical power. A custom wire harness is designed and manufactured to fit the specific geometric and electrical requirements of a particular product. This includes:

Exact Lengths: Each wire is cut to a precise length to run perfectly between two points within the product’s enclosure, eliminating messy, overly long wires or wires that are stretched too tight.

Specific Connectors: The harness is terminated with the exact connectors required to plug into the various printed circuit boards (PCBs), switches, sensors, and other components.

Bundling and Protection: The wires are bundled together using methods like cable ties, tubing, or braided sleeves. This protects the wires from abrasion and vibration, and makes the product assembly process much faster and less prone to error.

This is a field where “close enough” is not good enough. Precision and adherence to standards are everything.

Component Sourcing: The quality of the raw components is critical. This includes:

- Wire: The wire must have the correct gauge (AWG), stranding, insulation material, and color coding to meet the product’s electrical load and safety requirements.

- Terminals and Connectors: These must be from reputable brands (e.g., Molex, JST, TE Connectivity) or high-quality equivalents. Poor quality terminals can lead to loose connections and product failure. The crimping of the terminal to the wire is a critical quality point.

Certifications and Standards: For products sold in North America or Europe, the wire harness often needs to meet specific safety standards.

- UL (Underwriters Laboratories): Many applications require the use of UL-recognized components and that the harness assembly facility itself is a UL-certified wire harness manufacturer. This is a major indicator of a high-quality supplier.

- IPC/WHMA-A-620: This is the global industry standard for the acceptance criteria for cable and wire harness assemblies. A serious manufacturer will build and inspect their products according to this standard.

The Manufacturing Process:

- Cutting and Stripping: Wires are automatically cut to length and the insulation is stripped from the ends with high precision.

- Crimping: Terminals are attached to the wire ends using specialized crimping presses. The crimp height and pull force must be constantly monitored to ensure a secure electrical and mechanical connection.

- Assembly: The terminated wires are laid out on a “harness board,” which is a full-scale diagram of the harness. The wires are then routed and bundled according to the design.

- Testing: Every single custom wire harness must be 100% electrically tested before it leaves the factory. This is typically done with a “cirrus tester” or similar machine that checks for continuity (no open circuits) and isolation (no short circuits).

The search for a custom wire harness supplier is different from finding a general electronics assembler.

Look for UL Certification: This is one of the most important filtering criteria. A UL-certified facility has demonstrated that it has the processes and controls in place to produce safe and reliable harnesses.

In-House Testing is a Must: Ask to see their testing equipment and records. If a supplier does not perform 100% electrical testing on every harness, do not work with them.

Experience and Expertise: This is a niche field. Look for custom manufacturing companies that specialize in wire harnesses. They will have the right equipment, experienced technicians, and a deep understanding of the relevant standards.

Request Samples: Provide them with a drawing and ask for a “first article” sample. Meticulously inspect the crimp quality, the connector assembly, and the overall workmanship.

A faulty wire harness can be a nightmare, leading to intermittent product failures that are difficult to diagnose. Investing time in finding a top-tier custom wire harness supplier is a critical step in ensuring your electronic product is reliable and safe.

In custom product manufacturing, you don’t get what you expect; you get what you inspect. Quality is not something that can be “added” at the end of the production line. It must be built into every step of the process, from raw material sourcing to final packaging. A robust Quality Control (QC) strategy is your insurance policy against defects, delays, and damage to your brand’s reputation.

A comprehensive QC plan involves multiple inspection points throughout the production cycle. Relying on a single final inspection is a common but risky approach. For a detailed overview, it’s useful to understand the different types of inspection in production management.

Pre-Production Inspection (PPI): This inspection occurs after you have placed your order but before mass production begins. The inspector verifies that the factory has sourced the correct raw materials and components as specified in your tech pack. For a custom wire harness, this would mean checking the wire spools and connector boxes. For custom plastic parts, it would involve verifying the grade of the plastic resin. This early check prevents catastrophic errors where the entire production run is made with the wrong materials.

During Production Inspection (DPI): This is conducted when 15-20% of your order has been completed. The inspector goes to the factory floor and pulls a random sample of semi-finished or finished products to check against the golden sample and your specifications. The primary goal of a DPI is to catch any systemic issues early. If a problem is found in the first 20% of the run, it is far easier and cheaper to correct than if it is discovered after 100% of the products have been made.

Pre-Shipment Inspection (PSI): This is the most common type of inspection and the final checkpoint before your products are shipped. When the order is 100% complete and at least 80% packed, an inspector visits the factory to perform a final random inspection. This is a critical step in the process of inspection and quality control in manufacturing.

The PSI is based on a statistical sampling method known as AQL (Acceptance Quality Limit). Understanding what is AQL sampling and how to use it is fundamental for any importer. In essence, the inspector pulls a random sample of units (the sample size is determined by your total order quantity) and inspects them for defects.

Defects are typically categorized into three levels:

* Critical: A defect that poses a safety hazard to the user or violates regulations. (e.g., a sharp edge on a toy, faulty wiring). The acceptable limit for critical defects is always zero.

* Major: A defect that is likely to result in product failure, reduced usability, or is a very obvious visual flaw that would cause a customer to return it. (e.g., a product that doesn’t turn on, a large crack in a plastic housing).

* Minor: A small cosmetic flaw that does not affect the product’s function and is unlikely to be noticed by most users. (e.g., a tiny scratch on an inconspicuous surface).

Your AQL standard (e.g., AQL 2.5 for major defects, 4.0 for minor defects) determines how many of each type of defect are allowed in the sample before the entire shipment “fails” the inspection. If the shipment fails, you have the leverage to require the factory to rework the defective goods or remake the order before you release the final payment.

You have three main options for conducting inspections:

1. Yourself: The best option for control, but impractical and expensive for most businesses.

2. The Factory’s QC Team: All good factories have their own internal QC team. However, they are employed by the factory, so their interests are not perfectly aligned with yours. You should never rely solely on the factory’s internal QC.

3. Third-Party Inspection Company: This is the most common and recommended approach. You hire an independent company (or a sourcing partner that provides this service) to conduct the inspections on your behalf. They act as your unbiased eyes and ears in the factory, providing a detailed report with photos and findings. When considering this route, it’s important to know how to choose third party quality control services.

A rigorous QC strategy is not an expense; it is an investment that protects your capital, your customers, and your brand.

Your custom products have been manufactured, inspected, and approved. The final hurdle is getting them from the factory in China to your warehouse. International logistics is a complex field with its own language of acronyms and regulations. A misunderstanding at this stage can lead to costly delays and unexpected fees.

The first major decision is how to transport your goods.

Sea Freight: This is the backbone of global trade and the most common method for importers.

- Advantages: It is by far the most cost-effective option, especially for large, heavy shipments. As a general rule, why sea freight is cheaper than air freight comes down to the immense volume a container ship can carry.

- Disadvantages: It is slow. A shipment from China to North America or Europe can take 30-45 days or more. It is also more prone to delays due to port congestion or weather.

Air Freight: This involves shipping your goods on a cargo airplane.

- Advantages: It is much faster, with transit times typically ranging from 5-10 days.

- Disadvantages: It is significantly more expensive than sea freight, often 5-10 times the cost for the same volume. The cost is based on volumetric weight, so it is most suitable for small, lightweight, high-value goods.

For most custom product manufacturing projects, the bulk of the shipments will go by sea. Air freight is typically reserved for initial small batches, urgent restocks, or sending replacement parts.

If you are shipping by sea, you will encounter two main options:

FCL (Full Container Load): You rent an entire shipping container (typically 20ft or 40ft) for your exclusive use. You can fill it as much or as little as you like.

LCL (Less than Container Load): Your goods do not fill a whole container, so they are consolidated with other importers’ goods in a shared container.

The difference between FCL and LCL container shipping is a key consideration. FCL is generally cheaper per cubic meter and faster, as the container goes directly from your supplier to you. LCL is better for smaller shipments but involves more handling (and thus a higher risk of damage) and can have longer transit times due to the consolidation and deconsolidation process at the ports.

Incoterms are a set of universal rules that define the responsibilities of the seller (your supplier) and the buyer (you) in an international transaction. The two most common Incoterms for importers are:

EXW (Ex Works): You are responsible for everything. You must arrange to pick up the goods from the factory’s doorstep and handle the entire shipping process, including export customs in China and import customs in your country.

FOB (Free On Board): This is the most common and often recommended term for new importers. The supplier is responsible for all costs and processes to get the goods loaded on board the ship at the designated port in China. From that point forward, you are responsible for the sea freight, insurance, and import process. A detailed comparison can help you decide if FOB vs. EXW is better for importers.

Unless you are an experienced logistics professional, you will need to work with a freight forwarder. A freight forwarder is a company that arranges the entire shipping process on your behalf. They will book space on the ship or plane, handle the customs paperwork, and arrange for the final delivery to your door. They are an essential partner in the import process, helping you find what is the cheapest way to import from China while ensuring a smooth transit.

Navigating the world of custom product manufacturing in China is a complex, full-time job. It requires expertise in sourcing, engineering, quality control, and logistics. For most small and medium-sized businesses, trying to manage this entire process from thousands of miles away is a recipe for costly mistakes and overwhelming stress. This is where a professional sourcing partner, like Maple Sourcing, becomes an invaluable asset.

A sourcing partner is not a mere intermediary; they are an extension of your own team, located on the ground in China, dedicated to protecting your interests.

Finding Elite Suppliers: A sourcing partner goes beyond Alibaba. They have a curated network of trusted, pre-vetted custom manufacturing companies—factories that may not advertise internationally but are known for their quality and reliability. They can match your project’s specific needs, whether it’s for high-precision custom metal fabrication China or UL-certified custom wire harness assembly, with the perfect factory.

Professional Negotiation and Management: They bridge the cultural and language gap, negotiating not just on price but on all critical terms like MOQ, payment schedules, and IP protection. They manage the day-to-day communication with the factory, ensuring your project stays on track and that your instructions are understood perfectly. This level of knowhow about supplier relationship management is a core part of their value.

On-the-Ground Quality Control: A sourcing partner provides a complete quality assurance solution. Their own engineers and inspectors will be on-site at the factory, conducting pre-production, in-process, and final pre-shipment inspections. This ensures that quality standards are maintained throughout the production cycle, not just at the end.

Streamlined Logistics and Consolidation: They can manage the entire shipping process, working with their network of freight forwarders to find the best rates and routes. If you are sourcing multiple products from different factories, they can consolidate your goods into a single shipment, saving you significant money on shipping.

Risk Mitigation: From verifying factory legitimacy and implementing NNN agreements to resolving production issues and handling customs problems, a sourcing partner’s primary role is to mitigate risk. Their presence on the ground allows for rapid problem-solving that is impossible to achieve from overseas.

By handling the operational complexities, a sourcing partner frees you to focus on what you do best: growing your business, marketing your product, and serving your customers. The investment in a professional partner often pays for itself many times over by preventing costly errors, securing better pricing, and ensuring a higher-quality final product. To learn more about how this partnership works, you can explore our sourcing services.

The journey of custom product manufacturing in China is a pathway to creating unique, high-quality products that can define a brand and capture a market. It offers unparalleled opportunities for innovation and cost-effective scaling. However, success is not guaranteed. It is earned through meticulous planning, diligent execution, and a deep respect for the complexities of the process.

From finding and vetting specialized custom manufacturing companies to navigating the iterative design process for custom plastic parts or custom metal fabrication China, every step demands attention to detail. Establishing a robust quality control strategy is not optional; it is the foundation of a reliable product. Finally, understanding the nuances of international logistics is the final, critical link in a long and complex supply chain.

For businesses new to this world, the learning curve can be steep and the potential for error is high. Partnering with a professional sourcing company can transform this daunting challenge into a manageable and successful venture. By leveraging their local expertise, established networks, and on-the-ground presence, you can mitigate risks, ensure quality, and streamline the entire process from concept to customer. With the right strategy and the right partners, the immense manufacturing power of China can be harnessed to bring your unique product vision to life and build a lasting competitive advantage in the global marketplace. To begin your journey, we invite you to learn more about sourcing products from China.